Osram heralds new generation of IR lasers for LiDAR

Special chip design takes wavelength stability of edge emitters to a new level

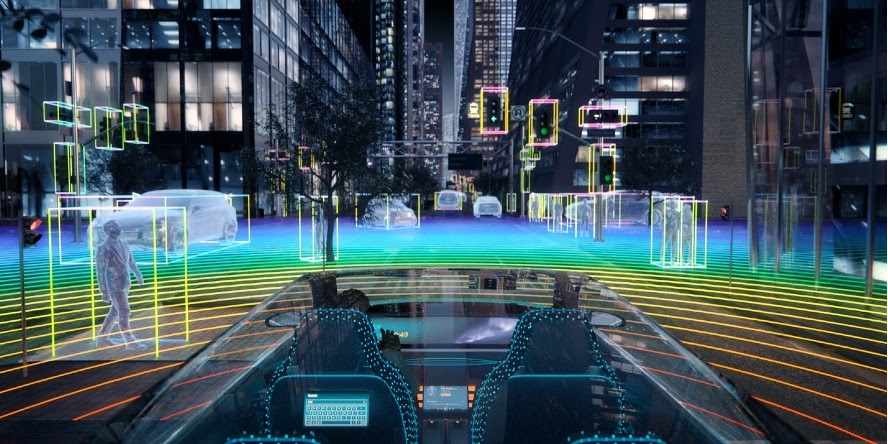

LiDAR is a key technology in the development of autonomous vehicles. In combination with radar and camera systems, it acts as the vision of the car, capturing its surroundings. LiDAR (Light Detection and Ranging) uses infrared light to create a precise, three-dimensional map of the environment. The better this visual information, the easier it is for the downstream systems to use it.

Up to now, the infrared lasers used for this purpose have deviations in wavelength stability of up to 40 nanometers as temperature in the component rises. As a result, the LiDAR system’s 'vision' was a bit blurred. A novel chip design from Osram now reduces the wavelength shift to just ten nanometers, enabling much clearer and sharper images of the surroundings.

Thanks to a newly developed chip design, Osram says that its edge-emitting lasers (EEL) can match and even exceed the wavelength stability of VCSELs at operating temperatures of up to 125degC typical for automotive applications.

This technological milestone in the development of infrared lasers allows the use of a much smaller wavelength filter on the detector, significantly improving the signal-to-noise ratio. This technological advance has been demonstrated in components with 'triple-junctions' such as three light-emitting surfaces stacked one on top of the other. In the future, it will be used in all Osram infrared lasers and offer enormous advantages to LiDAR system manufacturers.