Sending CPV into Space

Satellites could be powered by incredibly efficient modules featuring five-junction micro-cells and tiny glass lenses BY MATTHEW LUMB FROM GEORGE WASHINGTON UNIVERSITY

By far the most efficient class of technology for converting sunlight into electrical power is the high concentration photovoltaic (HCPV). Modules that are based on this technology use low cost lenses or mirrors to focus sunlight onto multi-junction cells with three or four junctions, to realise conversion efficiencies at the cell level that are nearing 50 percent. Note that the focusing of sunlight by factors of typically 500 to 1,000 is critical to increasing the bang-per-buck of this technology: it spawns a hike in conversion efficiency, as well as slashing cell costs, due to a dramatic reduction in the amount of compound semiconductor material required to deliver a given output.

The commercial success of HCPV has been thwarted by several factors, limiting this field to a handful of companies. Arguably the most damaging of thorns has been the rampant success of low-cost, large-area solar cell technologies, particularly crystalline silicon. But there are other issues, such as the requirement for precise two-axis tracking, which adds cost and complexity to an installation, while limiting packing density due to shadowing. Another impediment is that it is impossible to focus diffuse light with conventional optics, so utility-scale CPV is restricted to desert-like locations, where the diffuse sunlight fraction is small.

One glimmer of hope is that conventional, large-area silicon solar panels are now beginning to push firmly against their fundamental efficiency limits. So, if a large boost in HCPV efficiency came along at low cost, and were combined with the remarkably high energy yield available from two-axis tracking of the sun, this solar technology could be highly competitive once again.

Further cause for optimism is the emergence of myriad niche applications where the key requirement is maximising the number of watts per square meter, rather than the cost per watt. The former metric is the priority in remote and space-confined applications, such as bicycle and car-charging stations; in temporary DC microgrids, such as those used for disaster response; and in the application we will focus on in this article – space power.

Cell considerations

During the last decade, many CPV companies have closed up shop. But the majority of cell suppliers have not suffered the same fate, thanks to a healthy market for III-V multi-junction solar cells in space. Here they are the established industry leader, with numerous multi-junction solar cells on the market. Success stems from a different set of priorities: cost-per-watt is a secondary consideration, and topping the list is the specific power, judged in watts-per-kilogram, and the volumetric power density, evaluated in terms of watts-per-cubic-metre.

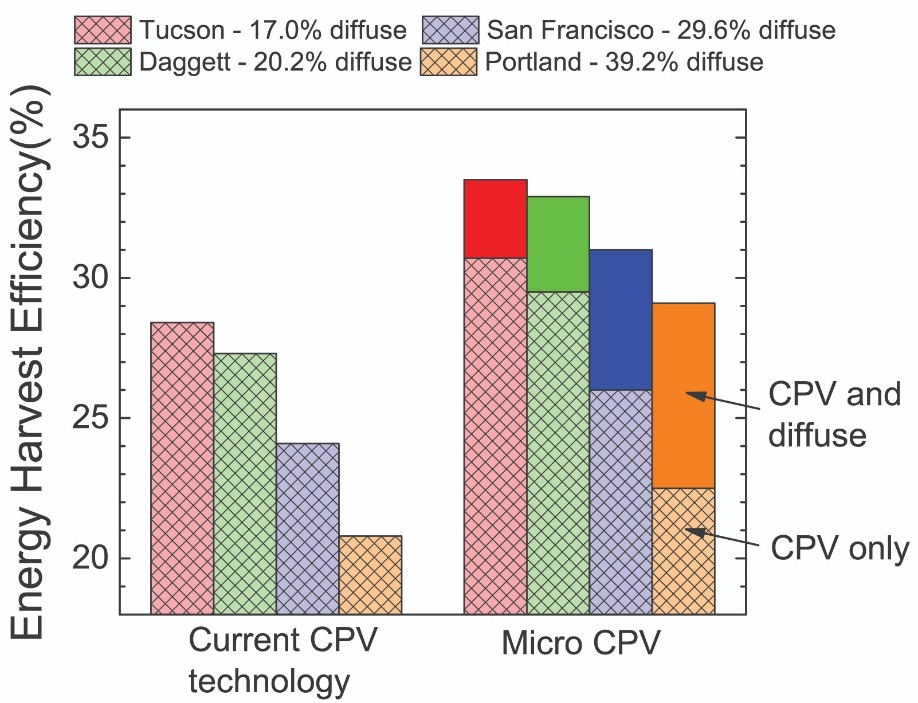

Figure 1. (a)-(e) The main features of the micro CPV design, which has been developed by a team that is led by researchers at George Washington University. Modules incorporating state of the art CPV microcells, all-glass optics and diffuse collection using off-the-shelf crystalline silicon solar panels. (f) A GaAs-based dual-junction microcell transfer printed on to a glass substrate. (g) A hexagonal array of dual-junction microcells under forward bias, operating as LEDs.

The need for a high specific power reflects the very high launch cost for putting anything in space. Regardless of what it is, it costs in the region of $10,000 per kilogram. So, to drive down launch costs, solar cell suppliers try to produce the lightest weight cells possible.

The other key consideration is the volume of the payload. To minimise this, extremely creative and hi-tech photovoltaic panel deployment systems are employed on satellites. They feature low profile modules and large-area, III-V multi-junction solar cells with industry leading performance.

Devices that work well on earth may not do so in space, due to the far higher levels of radiation that degrade material quality and reduce efficiency. To minimise this over the lifetime of the cell, suppliers encapsulate their devices in tens to hundreds of microns of cover glass. This coating shields the semiconductor layers from radiation, but adds significant weight to the final product.

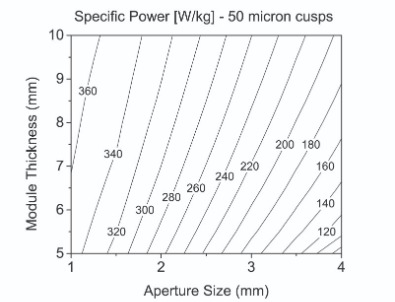

Figure 2. Predicted DC global energy harvest efficiency (annual kWh production / annual global resource on a two-axis tracker) in locations with different diffuse contents for conventional HCPV and a micro-CPV array.

CPV in space?

There have been several notable, successful experiments based on taking CPV panels into space. These efforts, aimed at exploiting the high efficiency of the technology to increase specific power, have focused on low concentration demonstrations that have failed to gain a strong foothold. But this time it could be different, thanks to the advent of a new type of CPV technology – micro CPV. Its timing could not be much better, given that multi-junction cells operating at one sun are reaching practical limits for efficiency and specific power; and the advent of reusable rockets, coupled with large increases in space traffic, could drive down launch costs.

Helping to develop a new generation of CPV technology for space is the US Department of Energy’s Advanced Research Projects Agency-Energy (ARPA-E). Through the programme MOSAIC – Micro-scale Optimized Solar-cell Arrays with Integrated Concentration – it is funding 11 teams with a total of $24 million.

The efforts that ARPA-E are supporting include those by our team at George Washington University, working in partnership with researchers at the US Naval Research Laboratory, Veeco, Northwestern University, MIT and X-Celeprint. Together, our collaboration is aiming to address some of the main obstacles facing conventional HCPV by marrying ground-breaking, ultra-high-performance five-junction cells with all-glass lens arrays and a glass backplane (see Figure 1 for an overview). Our glass lenses feature a novel, bifacial anti-reflection coating that provides an extremely high optical efficiency while concentrating sunlight by a factor of approximately 500.

One of the great strengths of our modules is that they can capture diffuse light, thanks to the incorporation of a bifacial, crystalline silicon solar panel. Attaching this to the CPV module injects a significant boost to the overall power output, especially in locations where a large fraction of the total solar resource arrives as diffuse illumination (see Figure 2).

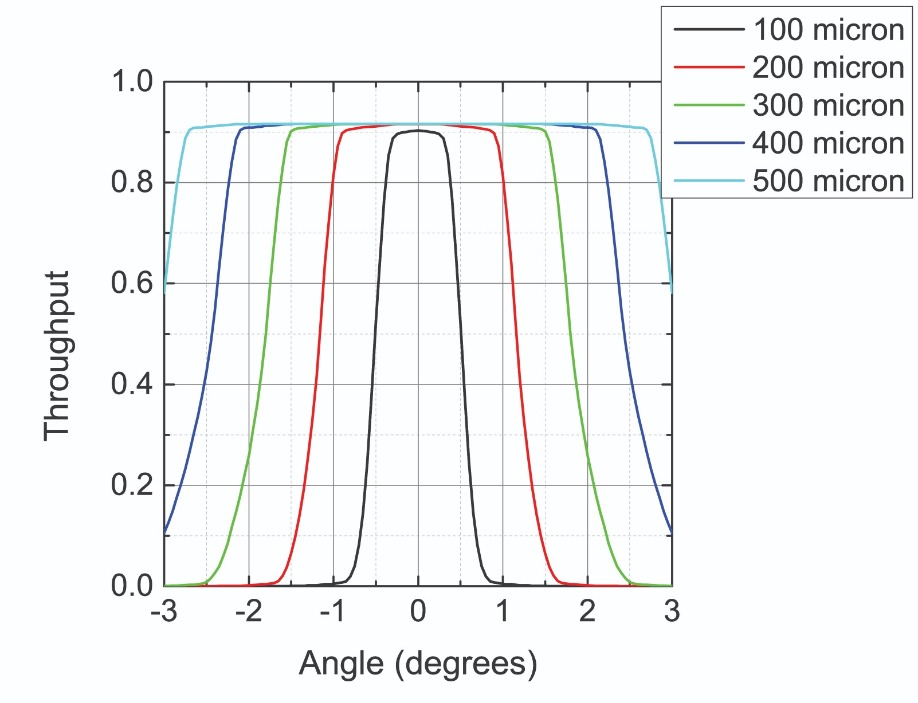

Figure 3. Specific power and volumetric power density for different lens designs for the five-junction CPV cell developed by the team led by researchers at George Washington University.

Our micro CPV module is also able to excel in efficiency. The apertures for our CPV cells are just 170 μm by 170 μm, so the devices are small enough to avoid the use of metal grid fingers when efficiently extracting current from the cell. Instead, a single metal contact is employed at the edge of the aperture, eliminating shadowing loss. Another benefit of using microscale cells is that they simplify thermal management. Thanks to this, cells can operate at lower temperatures, thereby churning out power at higher efficiencies.

We assemble our microcells with a micro-transfer printing process, a technology commercialized for PV by former CPV company and team partner Semprius. Note that this is also the core technology of our industry partner, X-Celeprint: it applies micro-transfer printing to a range of micro-optoelectronic applications.

Micro-transfer printing allows precise, parallel assembly of microscale devices that are removed from their native substrate with a wet etch procedure. In addition, we use micro transfer printing to heterogeneously integrate dual-junction, GaAs-based solar cells with triple-junction InP-based solar cells. The five-junction cells that result – featuring high quality, lattice-matched materials – capture a broad range of the solar spectrum. Do this at low cost, and it can be disruptive to conventional PV technology.

Our CPV module is well-suited for use in space. Its merits include: a very high radiation tolerance, thanks to shielding by the glass lens array; a reduced arcing risk between cells, due to their large separation; and a low profile module, enabled by focal lengths of just a few millimetres. Those dimensions allow units to be drop-in replacements for conventional panels, and be compatible with existing deployment techniques.

In missions to deep space, it’s actually an advantage to operate multi-junction cells at high concentration. That’s because this negates many of the difficulties associated with low-temperature, low-intensity environments. These issues, which include complications arising from hetero-barriers and trap states, are encountered on missions to parts of the solar system much farther from the sun.

Yet another strength of our CPV modules is that they have the potential to be far cheaper than large-area III-V solar cells. This benefit will become increasingly important in the future, due to decreasing launch costs.

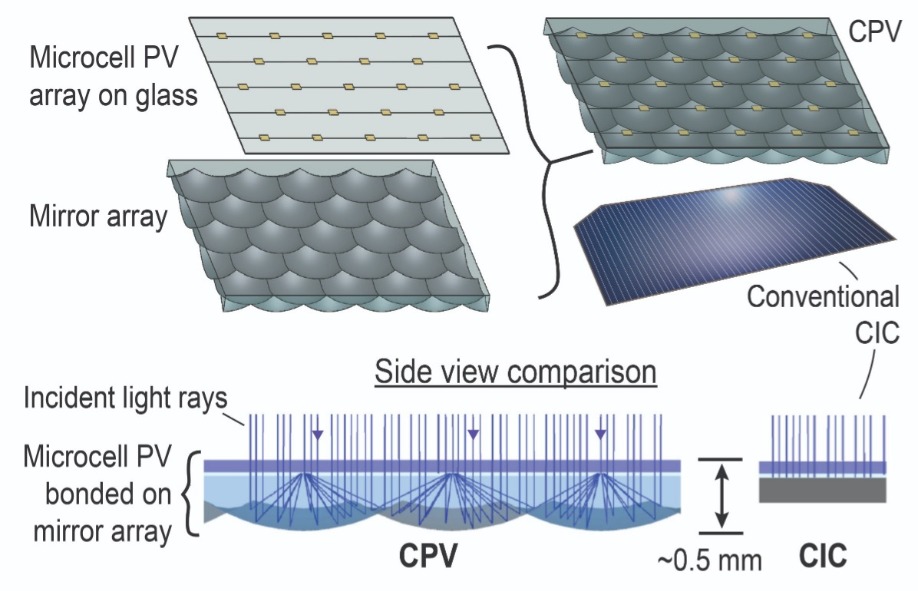

Figure 4. Optical throughput versus incident angle for glass lenses with a 1 mm by 1 mm aperture and 5 mm focal length for different CPV cell dimensions.

Sweet spots

Modelling suggest that the efficiency of our CPV cell in space peaks at roughly 200 suns. Go any higher and performances falls due to temperature-related losses and series resistance. Note that lower values of concentration are used in space than on earth, due to the lack of convective cooling, which impairs thermal management. A higher cell efficiency does help thermal management though, as less wasted power is required to be dissipated.

We have evaluated the specific power and volumetric power density of our module for different lens aperture sizes, while assuming all-glass lens arrays with square apertures (see Figure 3). In this study, our 1 mm by 1 mm lens aperture provides a concentration of about 35 suns, while the 4 mm by 4 mm aperture offers a concentration of 550.

The smaller lenses are compromised by a lower optical efficiency, due to a ‘cusp’ region that extends for about 50 μm along the perimeter of each lenslet. This flaw, resulting from the surface tension of glass as it cools in the mould, hampers the focusing of light from the cusp region. However, even with this imperfection and the lower concentration, the smaller lens yields a higher specific power. That’s because these lenses are lighter, thanks to the combination of their smaller apertures, and their lower lens curvature, due to a longer focal length.

Unfortunately, from the perspective of maximising the volumetric power density, it is better to use a lens with a shorter focal length. The highest density values coincide with concentrations that correspond to the peak cell efficiency.

This creates a conundrum that is not faced by the designers of conventional flat panel designs, which produce highest specific power when delivering their highest volumetric power density. However, there is a happy medium for micro-CPV modules in space: small aperture lenses with a short focal length. In future, it may be possible to make even lighter lens arrays using Fresnel lens concepts – this would improve the specific power even more.

Figure 5. A reflective microcell CPV array is hardly any thicker than a conventional coverglass-integrated space PV cell (CIC).

Wherever CPV systems are used, arrays must be pointed directly at the sun to maximise power. This is not as daunting to realise in space as it might first appear, as most satellites can track the sun to within a degree or so, using a variety of attitude control systems. However, the danger is that if the design employs a narrow acceptance angle, a significant pointing inaccuracy runs the risk of a power outage.

The good news is that it is easy to avoid this scenario, because the economics of space are in our favour. To highlight the way forward, we have considered the optical throughput efficiency for broadband illumination at varying incident angles, for a 1 mm square lens, 5 mm module thickness and a variety of CPV cell sizes (see Figure 4). This study shows that by oversizing the cell, a much wider angular acceptance is possible. There are penalties to pay, in the form of a slightly reduced cell performance – solar cells generally work best when uniformly illuminated – and, of course, a higher overall cost, due to an increase in semiconductor content. However, even with those oversized cells, the cost of the panel is still an order of magnitude lower than an equivalent one with no concentration.

The work described so far considers refractive optics for a space concentrator system. But that is not the only promising option: there is also much potential with a reflective concentrator geometry (see Figure 5). Those of us at George Washington University are pursuing this as well, in a partnership with a team at Penn State University, led by Chris Giebink. Modules are formed by printing microcells on a thin sheet of glass, which is subsequently bonded to a reflective lenslet array.

One of the primary merits of CPV modules with reflective optics is that they enable cells to operate near the thermodynamic limit of concentration, while the optics have a far lower aspect ratio – the thickness, divided by the aperture width, may be as low as 0.25. With such a design, mass can reach a new low, while increasing the angular acceptance for a given concentration ratio.

For example, for 170 μm by 170 μm cells operating at a concentration of roughly 35 suns, the total thickness of a practical concentrator can be as low as 0.5 mm – that is comparable to the thickness of existing coverglass-integrated space PV cells – while the angular acceptance can be as high as approximately ±5˚.

A practical challenge with this type of module is the extraction of heat from the cells, because they are embedded in low thermal conductivity glass.

This should be manageable, according to thermal modelling and experimental measurements on a similar, terrestrial microcell CPV. However, we can only be certain of this after we have experimentally tested this design.

We have no doubt that micro CPV offers exciting new opportunities for lightweight, low-cost, low-profile CPV arrays that set a new benchmark for efficiency. Armed with funding from ARPA-E, the new, state of the art CPV modules that we are developing using micro transfer printing promise to have benefits on earth and up in space.