How to make stable black perovskite

Queen Mary University team develops low temperature, aerosol-based process for creating stable, black-phase formamidinium perovskite

Researchers from Queen Mary University of London have developed a new process for producing stable perovskite materials to create more efficient solar cells.

The team focused on formamidinium perovskite or FAPbI3. This black crystal is more chemically stable than many other perovskites. Its optical properties are also much better suited to absorb light and produce electricity efficiently in a solar cell than existing perovskite materials. However, creating this black, stable form of the material is difficult, and it can often instead form a yellow phase that isn’t suitable for solar cells.

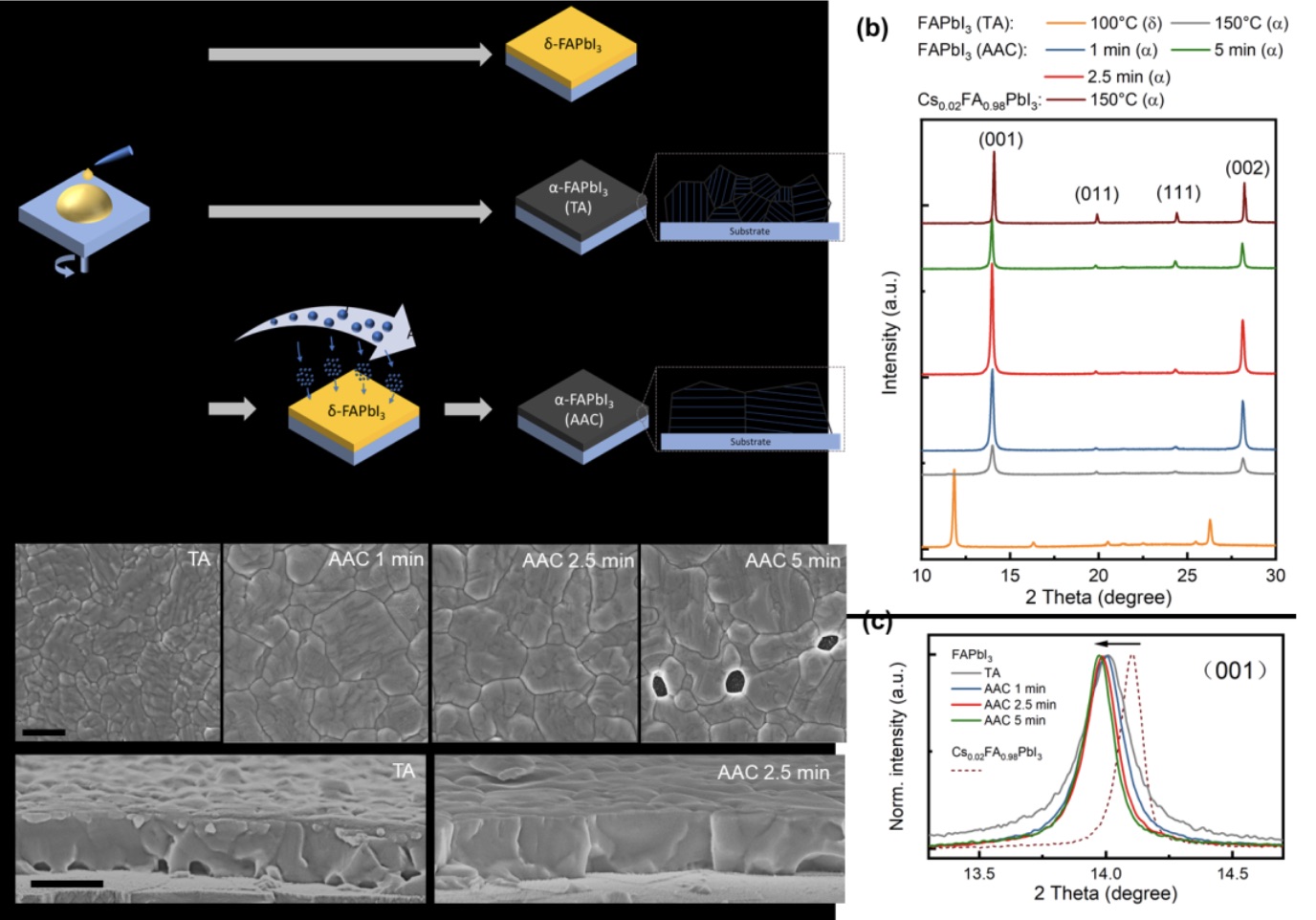

In the study, published in the journal Advanced Materials, researchers describe a new process for creating FAPbI3. One of the challenges with making FAPbI3 is that the high temperatures (150degC) used can cause the crystals within the material to ‘stretch’, making them strained, which favours the yellow phase. And whilst some previous reports have used small amounts of additional chemicals, or ‘additives’ to help form FAPbI3 under these conditions, it can be very hard to control the uniformity and amounts of these additives when making solar cells at a very large scale, and the long-term impact of including them is not yet known.

The novel approach described in the study instead exposes films of FAPbI3 to an aerosol containing a mixture of solvents at a lower temperature (100degC). The researchers found that they could form very stable black-phase FAPbI3 after just one minute, in comparison to other approaches that can take around 20 minutes. They also show that the lower temperatures used help to ‘relax’ the crystals within the material.

The figure above shows the crystallisation of FAPbI3 films; a. Schematic drawing of formation of α-FAPbI3through thermal annealing (TA) and aerosol assisted crystallisation (AAC). b. X-ray diffraction patterns (XRD) of FAPbI3 and Cs0.02FA0.98PbI3 films. c.Zoom-in figure of the (001) peak. d. Top: Surface scanning electron microscopy (SEM) images of FAPbI3films via TA and AAC processing of 1 min, 2.5 min and 5 min. Pinholes can be seen on AAC 5 min film. Scale bar is 1 μm for all images. Bottom: cross-sectional SEM images of FAPbI3 films viaTA and AAC of 2.5 min. Scale bar is 500 nm for both images.

Joe Briscoe, reader in Energy Materials and Devices at Queen Mary, said: “Pure formamidinium perovskite could produce perovskite solar cells that are more efficient and stable that those made with other commonly used hybrid perovskites based on methylammonium. This could be really important for commercialising this technology, particularly as the process can easily be scaled up.”

“In this study, we’ve demonstrated a novel, more efficient approach to create pure and stable black formamidinium perovskite FAPbI3. As our process uses an ‘inverted’ perovskite solar cell structure and lower annealing temperature, this also makes it very suitable for making flexible solar cells on plastic, which could have a lot of applications for example in clothing and vehicles.”

REF

‘Additive-free, Low-temperature Crystallization of Stable α-FAPbI3 Perovskite’ by Du et. Al (2021) Advanced Materials