Building Brighter, More Powerful Lasers Diodes

Laser diodes can be more powerful when they employ facets with equal reflectivity, and brighter when they features an architecture that trims the number of lateral modes

RICHARD STEVENSON REPORTS

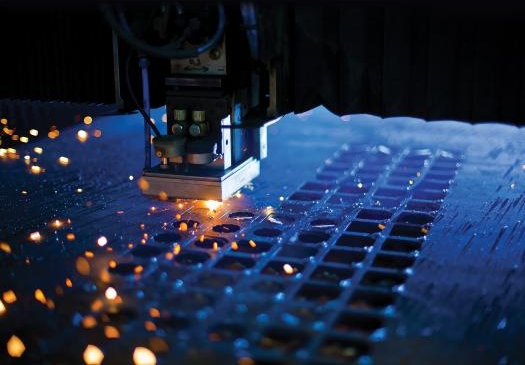

The GaAs-based laser is one of the longest selling, most established products within our industry. Invented in 1962, it had its first "˜killer application' in the late 1980s, when this infrared source started to read the binary data off of countless CDs. And more recently, further success has followed, with high-power versions of this chip cutting and drilling metals, and providing a pump source for various lasers.

Given this level of maturity, one might expect that today's improvements in performance are incremental. But judging by the papers on high-power near-infrared lasers at this year's Photonics West, that is certainly not the case. Significant advances in brightness, efficiency and output power have been reported by researchers from JDSU, nLight, FBH and Jenoptik, during a well-attended conference held in San Francisco from 7-12 February. These performance gains will help to improve the competitiveness of the high-power laser, while accelerating its sales as a capable alternative to the carbon dioxide laser, the traditional source for welding and cutting metals.

One of the biggest advances in laser output power has come from JDSU. At Photonics West 2015 a team of engineers announced that they had raised the bar for the output of broad-area lasers, with devices producing up to 33 W "“ it is claimed that typically output powers have been limited to 20-25 W.

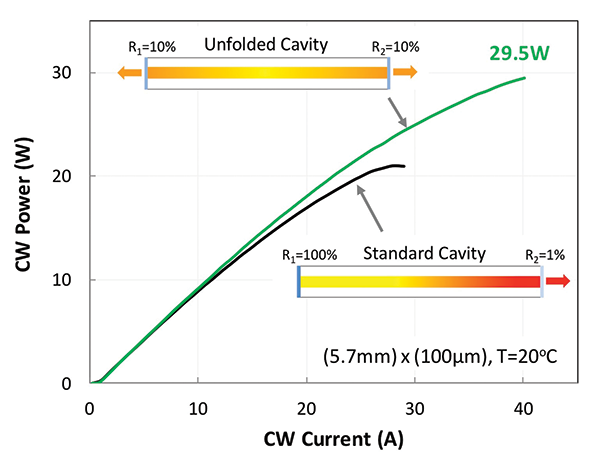

This breakthrough in output power has come from what is described as an unfolded cavity. This is formed from two mirrors with low reflectivity, and it creates a source emitting a similar output power from both facets. With 10 percent reflectivity at the facets, output power is 29.5 W, and this rises to 33 W with a switch to 4 percent facet reflectivity.

Corresponding author of the paper, Abdullah Demir, explains that if this type of laser is to be used in commercial applications requiring a single-fibre output, there may need to be a combining of the beams, while accounting for spatial and polarization characteristics. However, this is not required in applications where power is the only criterion that matters, which makes this device particularly well suited to gesture recognition, heating and illumination.

Demir believes that the most important aspect of the recent work of him and his colleagues has been the revealing of the size of linear and non-linear power-limitation mechanisms for GaAs-based lasers. This has been uncovered through calculations and measurements of a standard cavity, which has one mirror with 100 perfect reflectivity and another with

1 percent reflectivity, and an unfolded design with two mirrors with 10 percent reflectivity. The latter design produces very significant reductions in longitudinal spatial hole-burning and two-photon absorption.

The investigation by these researchers from Milpitas, California, determined that at an output of 20 W, the power penalty for two-photon absorption in a conventional design is four times that for an unfolded cavity with 10 percent reflectivity mirrors, and can hit 2.5 W. This non-linear process can occur when two photons are simultaneously absorbed by the waveguide to create free carriers. This causes losses increasing quadratically with photon density, while free carriers created by two-photon absorption can cause subsequent absorption losses increasing with the third power of photon density.

When it comes to longitudinal spatial hole-burning, it is calculated that a ten-fold reduction results from the switch to an unfolded cavity. However, the power penalty at 20 W for the conventional design is only around 1 W, so switching to an unfolded design potentially has its biggest impact on overall performance through a reduction in two-photon absorption.

Demir explains that longitudinal spatial hole-burning is caused by the inhomogeneous distribution of the carrier density, due to an inhomogeneous photon density distribution along the cavity. This effect is stronger in lasers with an asymmetric design, which explains why the unfolded design is less affected than the conventional equivalent.

Although the team's lasers are more powerful than conventional devices, calculations suggest even higher output powers should be possible, because the reductions in the power penalties associated with two-photon absorption and longitudinal spatial hole-burning are not as large as they could be.

"We want to understand the reason for the gap between theory and experiment," explains Demir, who will also be working with colleagues to develop more powerful designs with lower linear and non-linear losses.

One of the goals of many manufacturers of laser diodes is to not only improve the power of lasers emitting at around 915 nm to 980 nm, but also their brightness, because this makes them more attractive for many applications: fibre laser pumping, materials processing, solid-state laser pumping, defence applications and consumer electronics manufacturing.

A key consideration in this quest for higher brightness and power is the divergence of the laser, which should be as small as possible. Laser diodes do not produce circular beams, with divergence depending on the geometry of the direction: in the vertical direction, which is also known as the fast-axis and is perpendicular to the plane of the substrate, the divergence is limited by diffraction; but in the lateral direction that is referred to as the slow axis, wider apertures deliver more power at the expense of greater divergence.

Figure 1. Researchers at JDSU have increased the output from their laser by turning to an unfolded cavity that employs two mirrors with a facet reflectivity of 10 percent.

To improve the brightness along the slow axis, nLight of Vancouver, Washington, has developed a technology that breaks the traditional relationship between divergence and aperture width by trimming the number of allowed modes in the slow-axis direction.

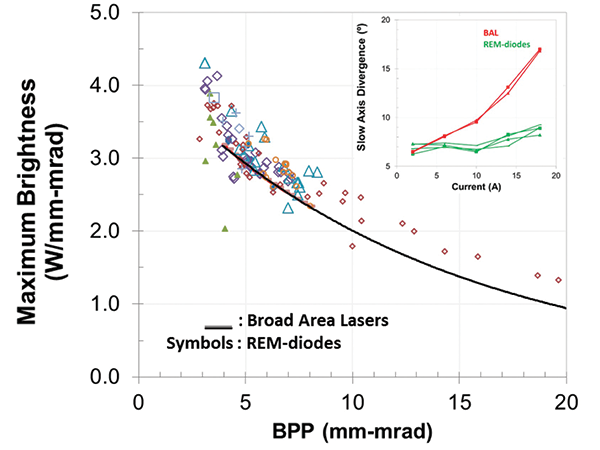

"We have demonstrated the highest slow-axis brightness for a broad-area laser," claims corresponding author Manoj Kanskar, who points out that a maximum brightness of 4.3 W/mm-mrad has been measured for one of the reduced-mode diode designs. "This is 48 percent higher compared to the brightest standard broad-area device we have produced in the past."

Compared to the previous generation of laser, which did not feature a reduced-mode technology, the latest devices that sport a reduced mode technology can exhibit the same beam parameter product (the product of the aperture width of the beam and its divergence), while emitting up to 20 percent more power before roll-over. What's more, they can deliver a higher electrical"“to-optical conversion efficiency.

These attributes strengthen the case for using diodes, rather than bars, to couple to fibres. "We are able to extract more ex-facet power, as well as fit more power into a given fibre diameter, due to the fact that they are higher brightness, and there is no thermal crosstalk," claims Kanskar. A lower part count for the same output power leads to a lowering of the dollars-per-Watt.

Engineers from nLight have placed 12 diodes into a package to create a source that, when driven at 17 A, produces up to 163 W of light that can be coupled into a fibre with a diameter of 105 mm and a numerical aperture of 0.15 (see Figure 2). "We are able to achieve this because we have reduced the slow-axis divergence by a factor of two compared to a standard broad-area laser," says Kanskar.

Reliability tests on the reduced-mode lasers and the previous generation of devices suggest that the latest emitters are more reliable. Kanskar claims that this is to be expected, as the footprints of the reduced-mode lasers are larger, so they will have a lower thermal and series resistance

Shrinking stripes

Reducing the number of lateral modes has also held the key to the high performance of lasers fabricated by scientists from the Ferdinand Braun Institute in Berlin, Germany. By combining advanced epitaxial designs with facet passivation and 30 μm-wide stripes that cut off higher order lateral modes, the team could produce diodes delivering more than 7 W at an efficiency in excess of 50 percent, while realising a beam parameter product of around 1.5 mm-mrad.

"For the first time, this corresponds to a higher brilliance than conventional single-mode lasers, which deliver around a Watt in 0.3 mm-rad" says lead author of the paper, Paul Crump. Brightness is also better, at 4.7 W mm-1 rad-1, rather than around 3 W mm-1 rad-1.

Reducing the lateral beam parameter product potentially allows laser diodes to directly access the majority of materials processing markets for the first time, the largest of which is deep metal cutting. "To cut deep holes, we require a high power density to be delivered within a narrow angle," says Crump.

The scientists have also investigated a tapered laser. These novel emitters combine a single-mode region at the rear facet with a tapered amplifier, restricting the device to one lateral mode that should minimise the beam parameter product. Such a goal has been realised, with around 5 W delivered with a beam parameter product of around 1.5 mm-mrad, but this comes at the expense of inferior efficiency "“ it is around 40 percent. Other weaknesses of these tapered lasers are that they emit more than 1 W of stray light, and they operate with a complicated astigmatic beam.

Figure .2 Engineers at nLight fabricated a range of reduced-mode laser diodes with beam parameter products in the range 915 nm to 980 nm. The solid curve represents the maximum brightness for a particular beam parameter product, while the symbols are the average values for various reduced-mode diodes that have been explored. The inset showcases the lower slow-axis divergence of the reduced mode (REM) diode compared to a broad area laser (BAL).

Another approach that Crump and his co-workers have pursued to trimming the beam parameter product is to introduce lateral anti-guiding structures. These have paid dividends in prototype devices with 90 μm stripes, where the beam parameter product has been cut from 4 mm-mrad to 3 mm-mrad without compromising efficiency.

"However, the devices with narrow stripes do not show comparable improvement in the beam parameter product, even though the number of guided modes is strongly reduced," says Crump. "This indicates that there are other limits than simply the number of modes present."

Designing devices that suppress factors known to limit the beam parameter product is one goal for the team. In addition, the scientists want to gain a better understanding of the remaining limits for the beam parameter product, as well as working to further increase efficiency and power.

Better barsAt Jenoptik, researchers have been improving the performance of high-efficiency laser bars emitting in pulsed mode at around 880 nm and 940 nm. One of the highlights of these efforts are 1.5 mm-long bars emitting 1 kW at 880 nm with a fill factor factor "“ the ratio of pumped bar area to total bar area "“ of 75 percent. The same output was also possible from 940 nm, 4 mm-long bars with a fill-factor of 50 percent that were driven with far longer pulses.

Agnieszka Pietrzak, lead author of the paper, describes these results as "definitely very good and competitive". However, she adds that record-breaking results are not the primary objective for the team: It is to build reliable, powerful devices meeting customer specifications.

The 1 kilowatt bars are still being developed, but at Photonics West the company did launch a lower power product: 500 W bars emitting at 880 nm. To do this, in the last 12 months engineers have increased the output power of 1.5 mm bars from 300 W up to a reliable 500 W. With a spectral width (95 percent power content) of 6 nm or less, and a slow-axis divergence of about 11 degrees, these lasers meet requirements for providing a pump source for Internal Fusion Energy Lasers.

Pietrzak will not discuss the technologies behind the improvements in performance in more detail than that provided in the paper. In that account, it is revealed that increases in carrier confinement and a reduction of the laser structure resistivity have boosted the output power of the devices, and that optical confinement in the lateral direction has been strengthened with an additional waveguiding along the electrical contact.

One of the next targets for the team is to improve the wall-plug efficiency of its 940 nm, 1 kW bars, for reliable operation.

A higher efficiency, which will be targeted initially via an increase in fill-factor, trims the thermal load and should lead to a narrowing of spectral width and beam divergence.

Those attending Photonics West 2016 may get to hear whether the team from Jenoptik have succeeded in that endeavour, and whether the researchers at JDSU, nLight and FBH have also made further progress.

This conference has a great track record in highlighting the progress in high-power laser diodes, and judging from the latest presentations, there is still the opportunity to deliver significant improvements in the performance of these solid-state emitters.