Smartkem says OTFTs are the future of microLEDs

Organic transistor approach eliminates costly mass transfer and laser welding processes

Despite the recent news that Apple has abandoned its in-house microLED display project, Smartkem, a UK-based developer of semiconductor polymer transistors, says its low cost solution highlights the inherent advantages of microLEDs over OLEDs.

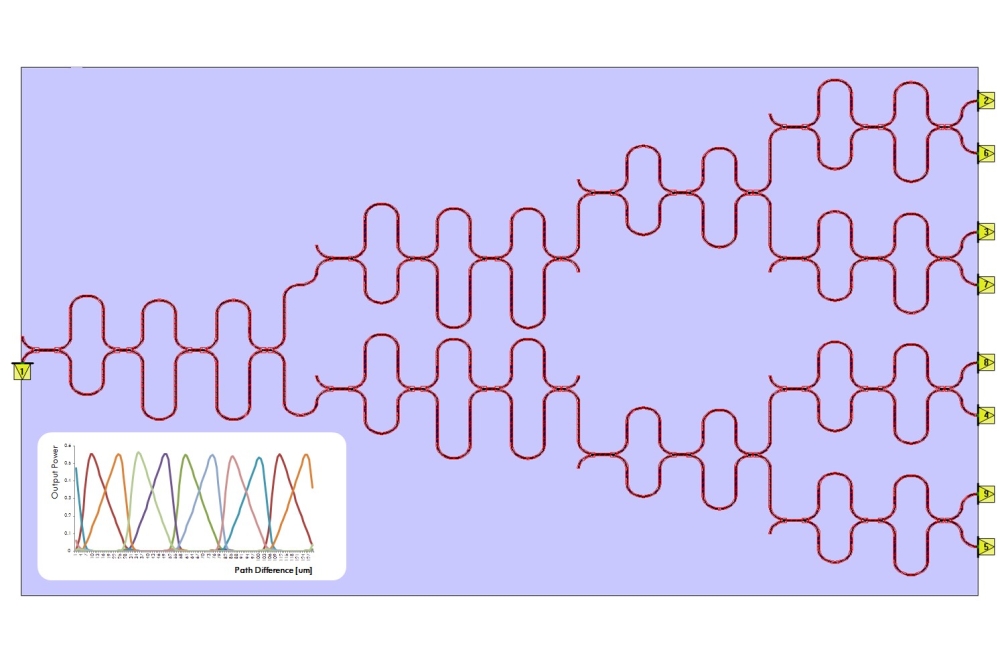

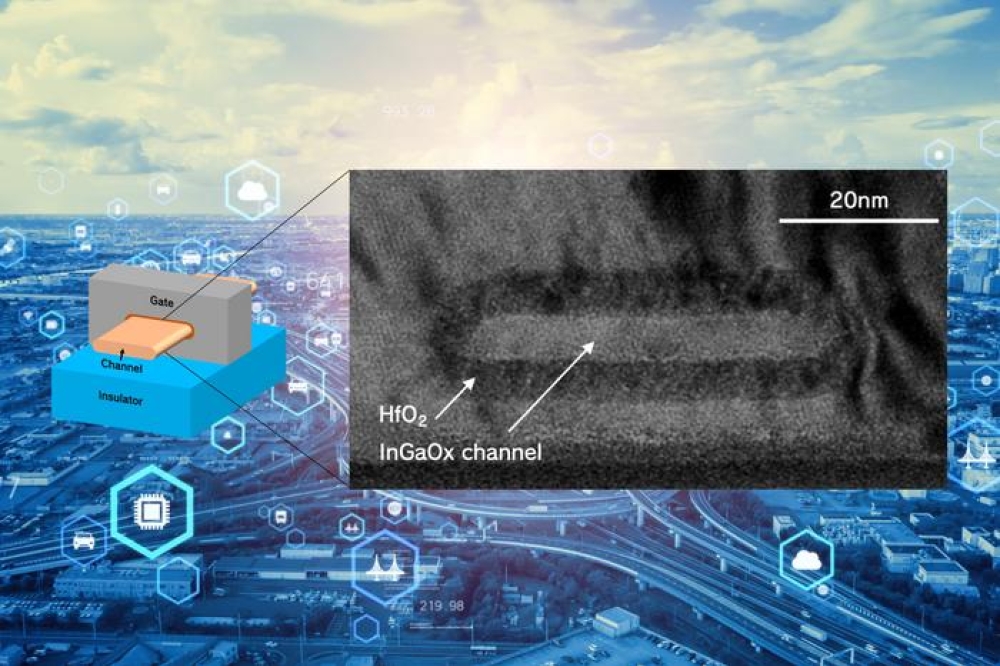

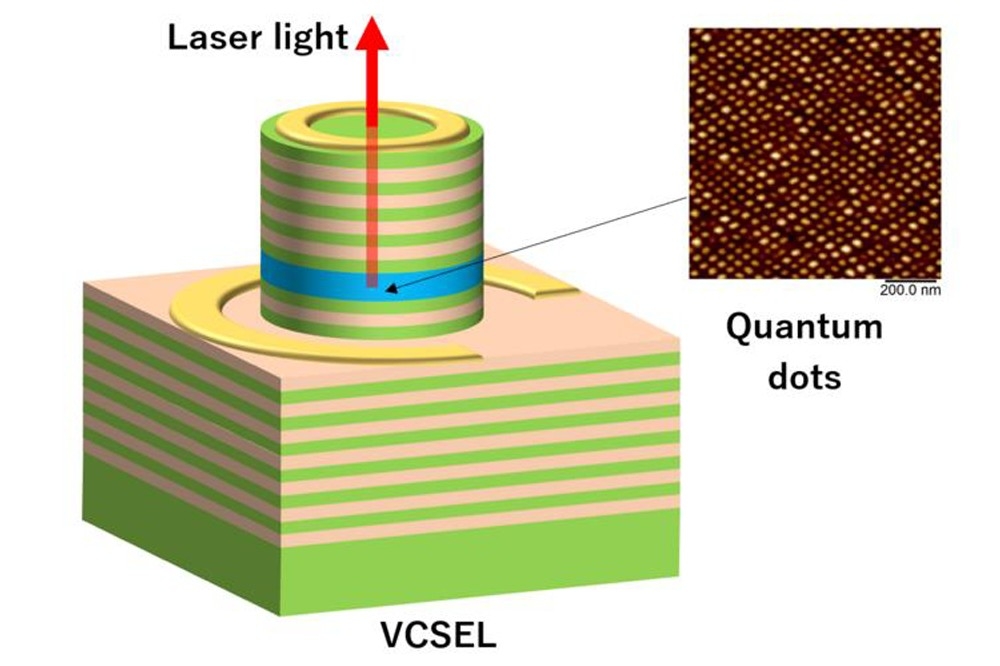

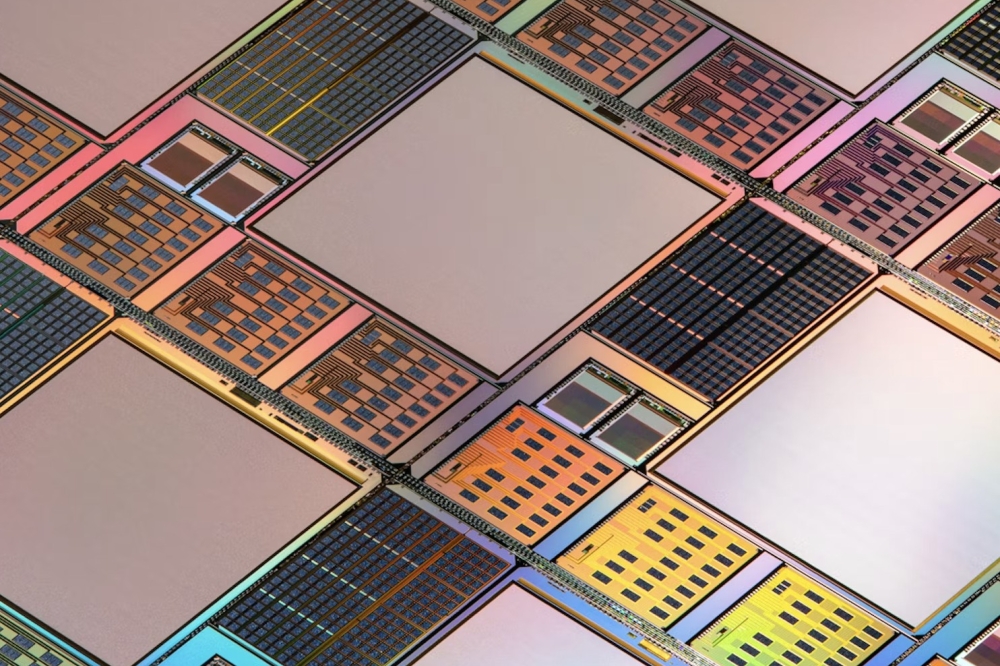

Smartkem has created the first monolithic microLED display using organic transistor technology (OTFTs. The company's semiconductor inks are solution-deposited at low temperature (80°C compared to 300°C industry standard), meaning its transistors can be processed directly on top of microLEDs, eliminating the (costly and imprecise) mass transfer and laser welding processes currently used to manufacture microLED displays.

Smartkem has also recently announced two joint development agreements with Taiwan-based companies to manufacture microLED displays using Smartkem’s OTFTs, as well as announcing a technology transfer agreement with the ITRI in Taiwan. This, says Smartkem, enables display manufacturers access to product prototyping to accelerate product commercialisation.

Smartkem adds that Samsung's recent announcement that it will be launching its first microLED wearable display suggests that industry giants still recognise the inherent advantages of microLEDs over OLEDs. Namely, high durability, extremely strong brightness, a de-coupled production process and high aperture ratio.