Rice lab turns GFR plastic into SiC

Process upcycles hard-to-dispose-of plastic into potentially usable chip material

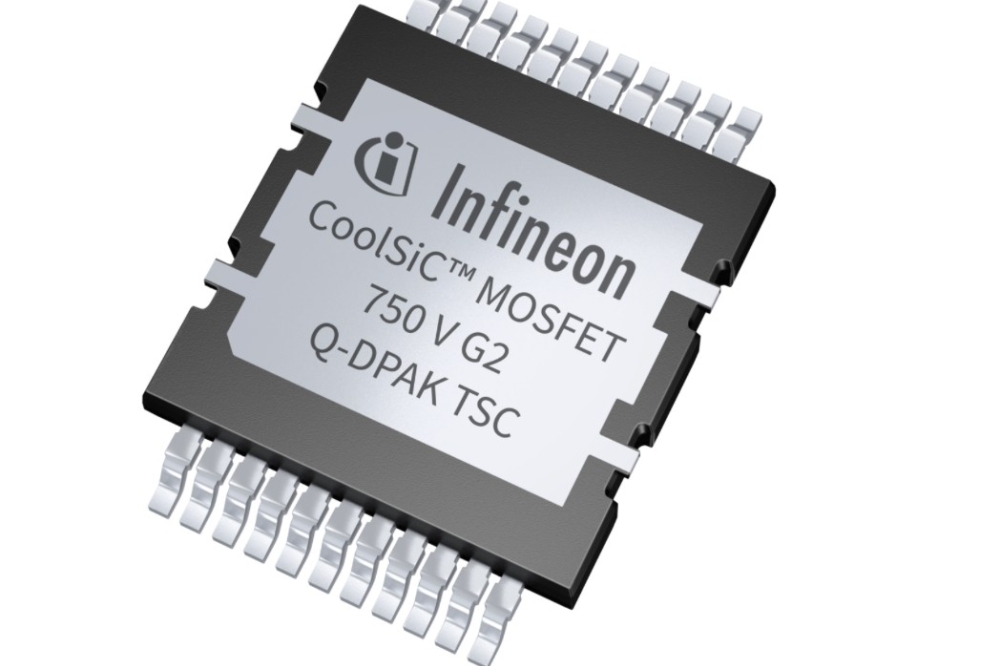

According to a study published in Nature Sustainability, Rice University researchers and collaborators have developed a new, energy-efficient upcycling method to transform glass fibre-reinforced plastic (GFRP) into SiC.

GFRP, a strong and durable composite material, is widely used in everything from aircraft parts to windmill blades. But the qualities that make it robust also make it difficult to dispose of.

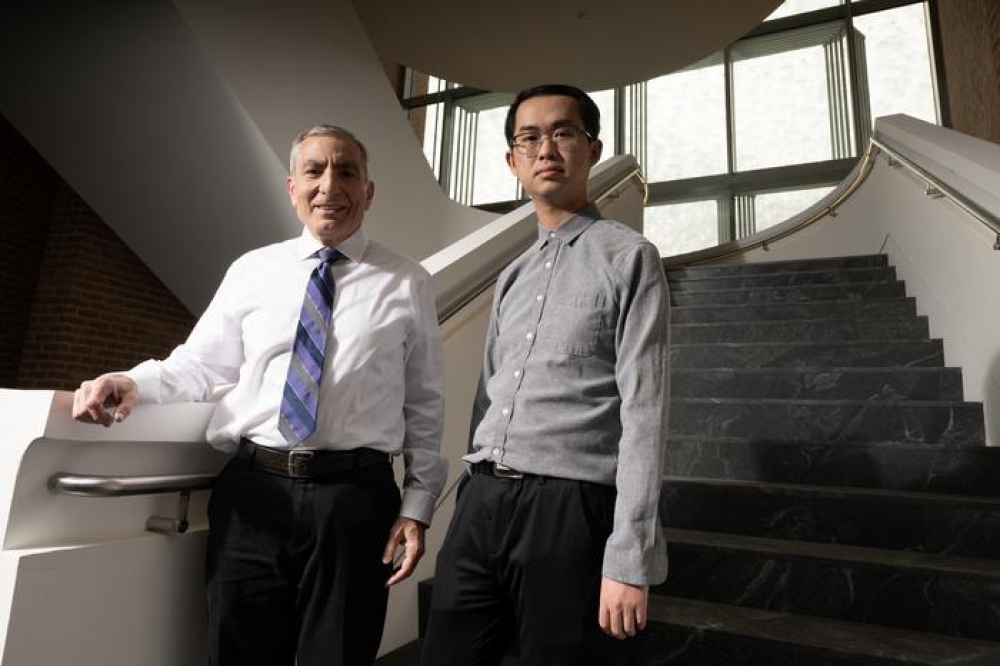

“GFRP is used to make very large things, and for the most part, we end up burying the wing structures of airplanes or windmill blades from a wind turbine whole in a landfill,” said James Tour, a professor of chemistry and of materials science and nanoengineering. “Disposing of GFRP this way is just unsustainable. And until now there has been no good way to recycle it.”

While some have tried to develop approaches using incineration or solvolysis to get rid of GFRP, Yi Cheng, a postdoctoral research associate who works in the Tour lab, said such processes are less than ideal because they are resource-intensive and result in environmental contamination.

“This material has plastic on the surface of glass fibre, and incinerating the plastic can generate a lot of toxic gases,” Cheng said. “Trying to dissolve GFRP is also problematic as it can generate a lot of acid or base waste from the solvents. We wanted to find a more environmentally friendly way to deal with this material.”

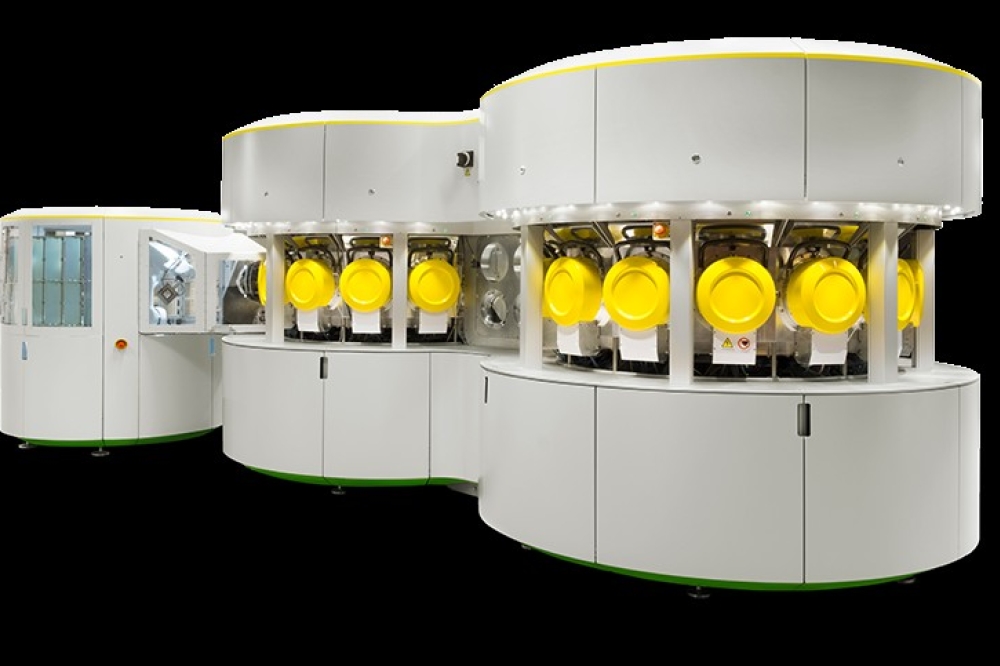

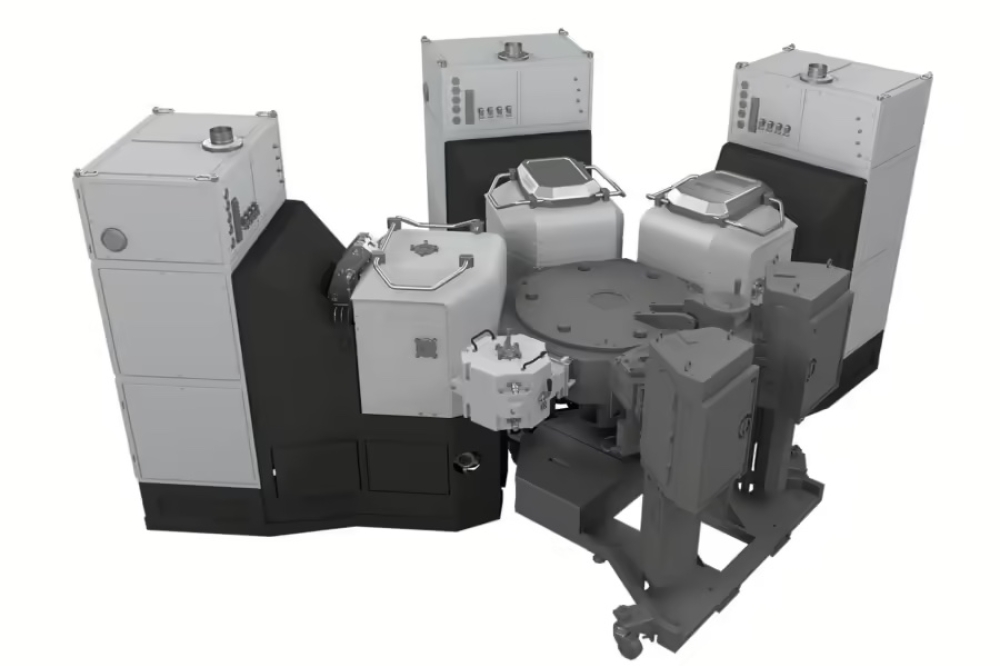

Tour’s lab has already made headlines for developing new waste disposal and recycling applications using flash Joule heating, a technique that passes a current through a moderately resistive material to quickly heat it to exceptionally high temperatures and transform it into other substances. Tour said when he learned of the issues involved with GFRP disposal from colleagues at the Defense Advanced Research Projects Agency, he thought that this kind of turbo-heating could transform GFRP into SiC.

“We already knew that if we heat the mixture of metal chloride and carbon by flash Joule heating, we could get metal carbide ⎯ and in one demonstration, we made SiC,” Tour said. “So we were able to leverage that work to come up with a process to transform GFRP into SiC.”

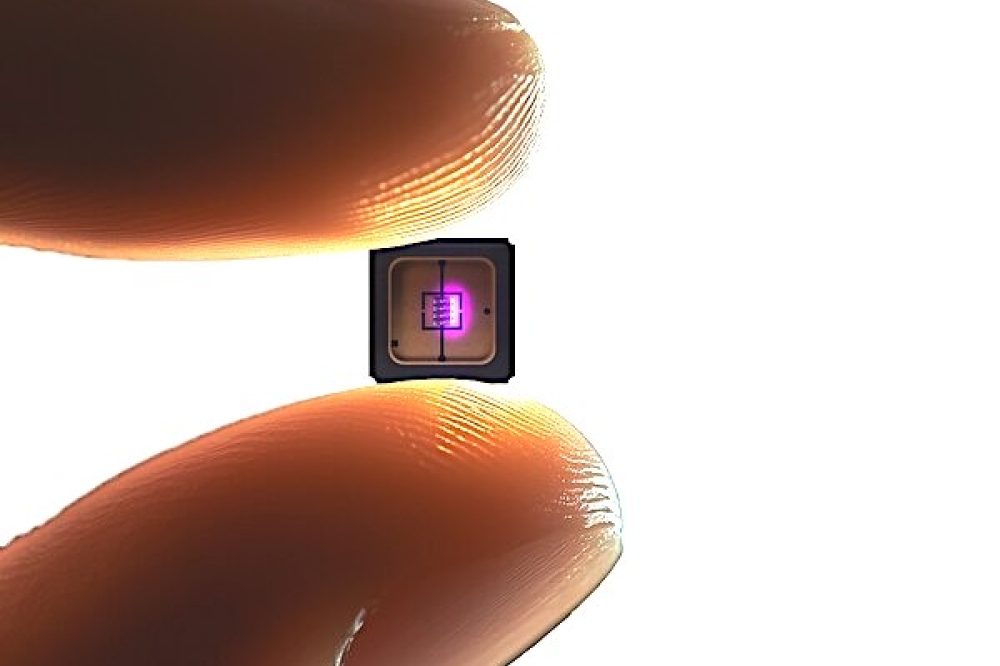

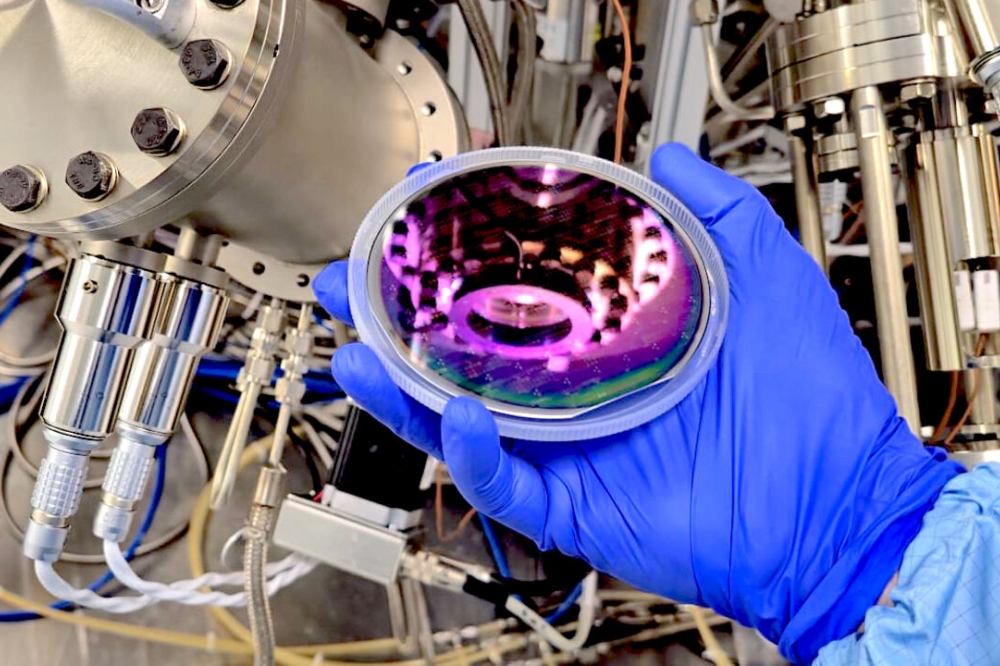

This new process grinds up GFRP into a mixture of plastic and carbon and involves adding more carbon, when necessary, to make the mixture conductive. The researchers then apply high voltage to it using two electrodes, bringing its temperature up to 1,600-2,900 degC .

“That high temperature facilitates the transformation of the plastic and carbon to silicon carbide,” Tour explained. “We can make two different kinds of SiC, which can be used for different applications. In fact, one of these types of SiC shows superior capacity and rate performance as battery anode material.”

While this initial study was a proof-of-concept test on a bench scale in the laboratory, Tour and colleagues are already working with outside companies to scale up the process for wider use. The operating costs to upcycle GFRP are less than $0.05 per kilogram, much cheaper than incineration or solvolysis ⎯ and more environmentally friendly.

It will take time ⎯ and some good engineering ⎯ to appropriately scale up this new flash upcycling method, Tour said.

The research was supported by the US Air Force Office of Scientific Research (FA9550-22-1-0526), the US Army Corps of Engineers (W912HZ-21-20050) and Rice University.