Beneq ALD GaN tool qualified by Asian chip maker

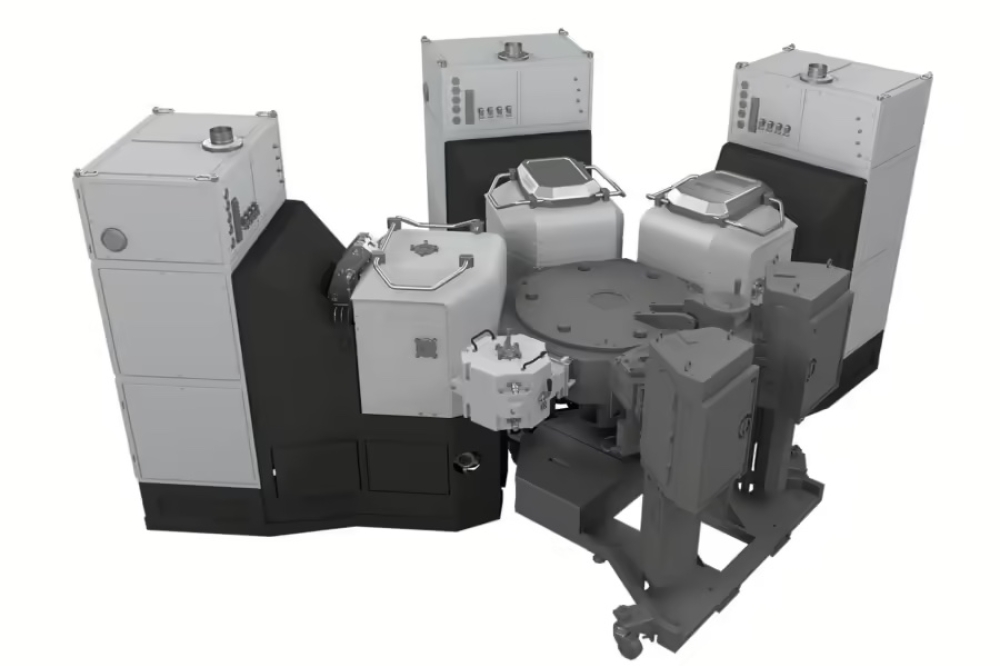

Finland-based Beneq has announced that its Transform ALD cluster tool has been qualified for volume production of GaN-based power devices on 8 inch GaN-on-Si wafers by a Tier 1 GaN power device manufacturer in Asia.

Seventeen Beneq Transform tools are now in operation globally for GaN device production and technology development, according to the company.

"Qualification by a Tier 1 GaN power device manufacturer underscores the strength of our Transform platform and its leading role in GaN manufacturing," said Pasi Meriläinen, VP, semiconductor ALD at Beneq. "We remain focused on enabling our customers' production goals through robust, application-driven ALD solutions."

The system enables a proprietary three-step process - plasma-based surface pre-cleaning, plasma-enhanced ALD (PEALD) of interfacial layers, and thermal ALD of dielectric films—executed under continuous vacuum.

This architecture ensures high-quality interface engineering and process reliability, which is critical for wide-bandgap materials such as GaN and SiC. Additional capabilities include nitride film deposition (e.g., AlN, SiN) and thermal ALD of films such as Al₂O₃, AlN, SiO₂, and HfO₂, offering flexibility across GaN HEMTs, ICs, and vertical devices.

Beneq is further advancing its GaN process capabilities through a collaboration with Imec as a member of its Industrial Affiliation Program (IIAP). A recently commissioned Transform tool at Imec expands the joint R&D in GaN surface treatments and dielectric integration started two years ago.