Wolfspeed unveils 2300V SiC Module

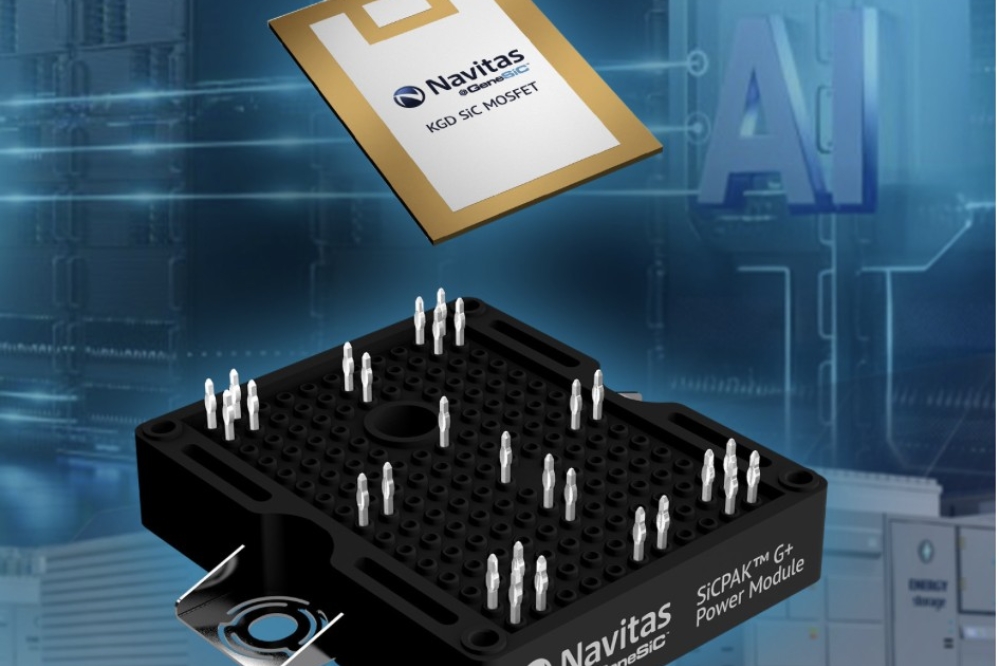

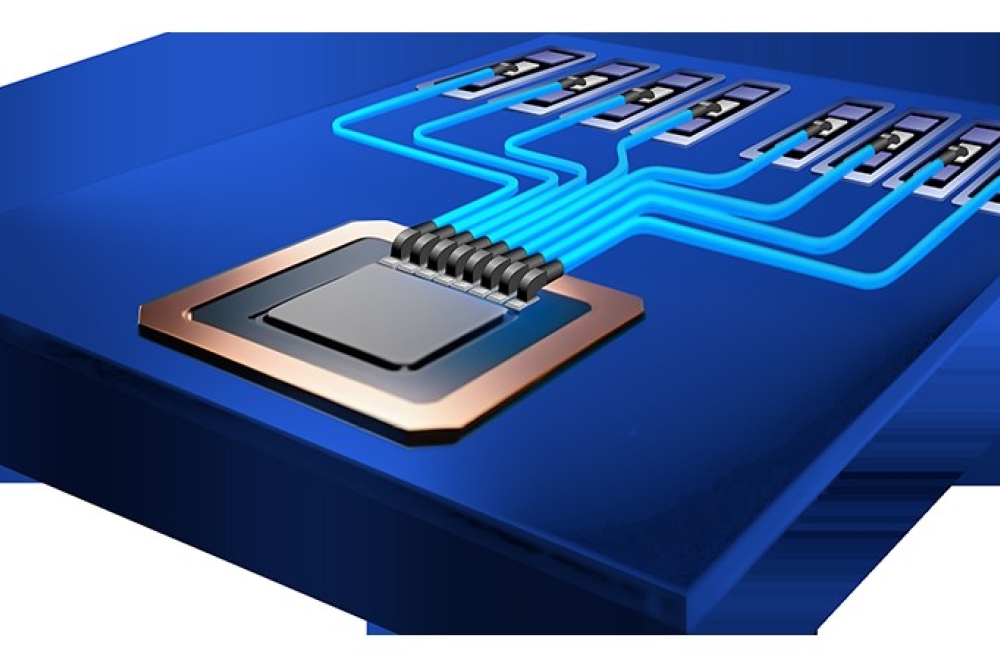

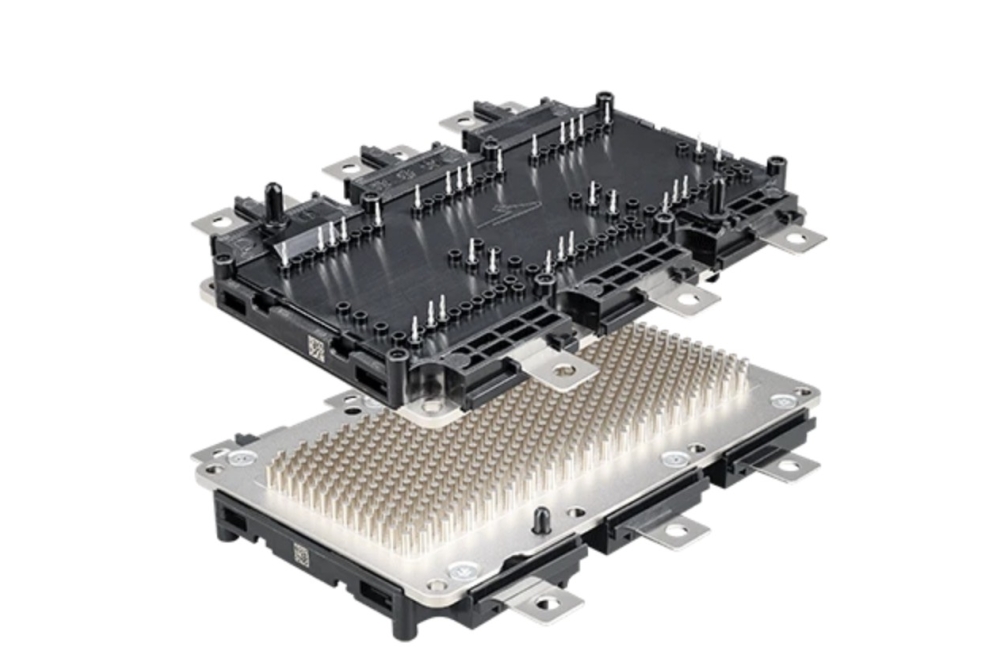

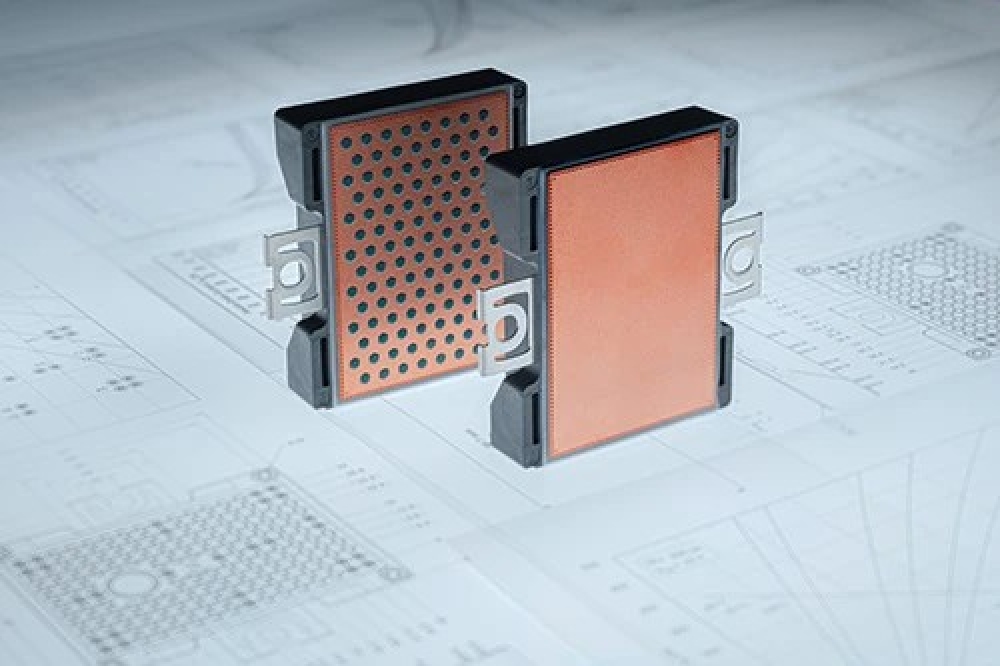

Wolfspeed has unveiled a SiC module, which it claims will transform the renewable energy, energy storage, and high-capacity fast-charging sectors through improved efficiency, durability, reliability, and scalability.

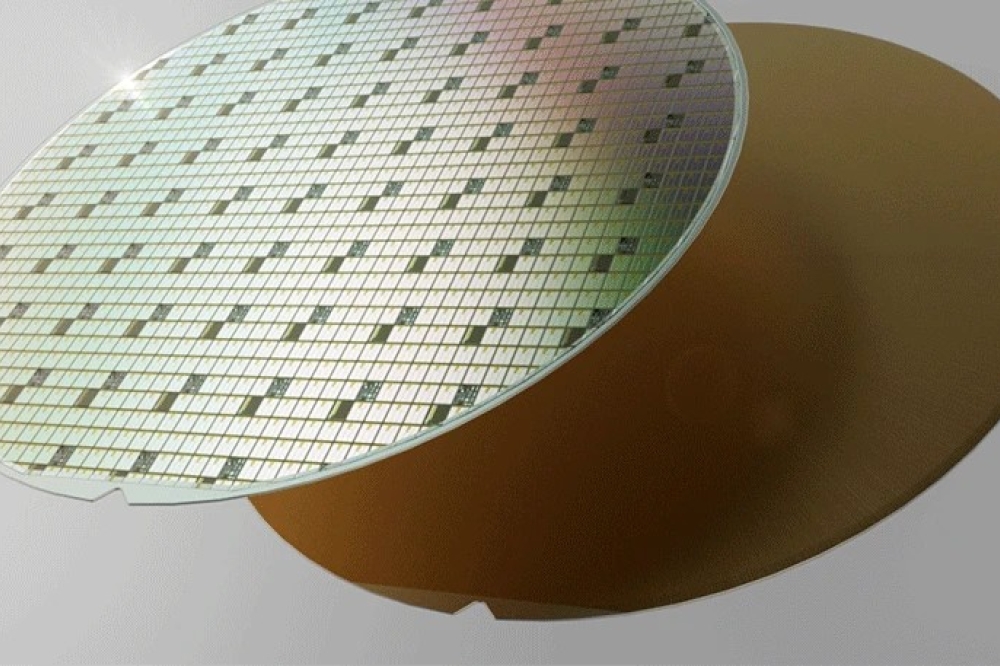

The 2300V baseplate-less SiC power modules for 1500V DC Bus applications were developed and launched using Wolfspeed’s s 200mm SiC wafers.

Wolfspeed also announced that it is partnering with EPC Power, a North American utility-scale inverter manufacturer. EPC Power will be employing the modules in utility-grade solar and energy storage systems, which offer a scalable high-power conversion system and high-performance controls and system redundancy.

“The solar and energy storage market remains among the fastest-growing segments of the renewable energy industry. As the pioneers of SiC, we are driven to create solutions that will open the door to a new era of modern energy,” said Jay Cameron, Wolfspeed SVP and general manager, Power. “Energy efficiency, reliability, and scalability are top of mind for our customers, such as EPC Power, who recognise the substantial advantages Wolfspeed’s SiC brings to the table.”

“SiC devices open the door to a step-change in inverter performance and reliability. With our commitment to extreme reliability, performance, and security in our new ‘M’ inverter while also forging a deep commercial relationship with key suppliers, Wolfspeed was the obvious choice,” said Devin Dilley, president and chief product officer, EPC Power.

Wolfspeed says its 2300V modules will improve system efficiency, while reducing the number of passive components. They offer 15 percent greater voltage headroom compared to similar SiC modules, improved dynamic performance with consistent temperature stability, and a substantial reduction in EMI filter size.

The technology is also said to achieve a 77 percent reduction in switching losses over IGBTs and a 2-3x reduction in switching losses for SiC devices intended for 1500V applications.

The modules feature an optimised Failure in Time rate for continuous 1500V DC operation and improved cosmic ray susceptibility compared to a 2000V design. When used in a two-level implementation, 2300V modules reduce the amount of potential single points of failure across the system.