RENA announces single-wafer cleaning and etching tool

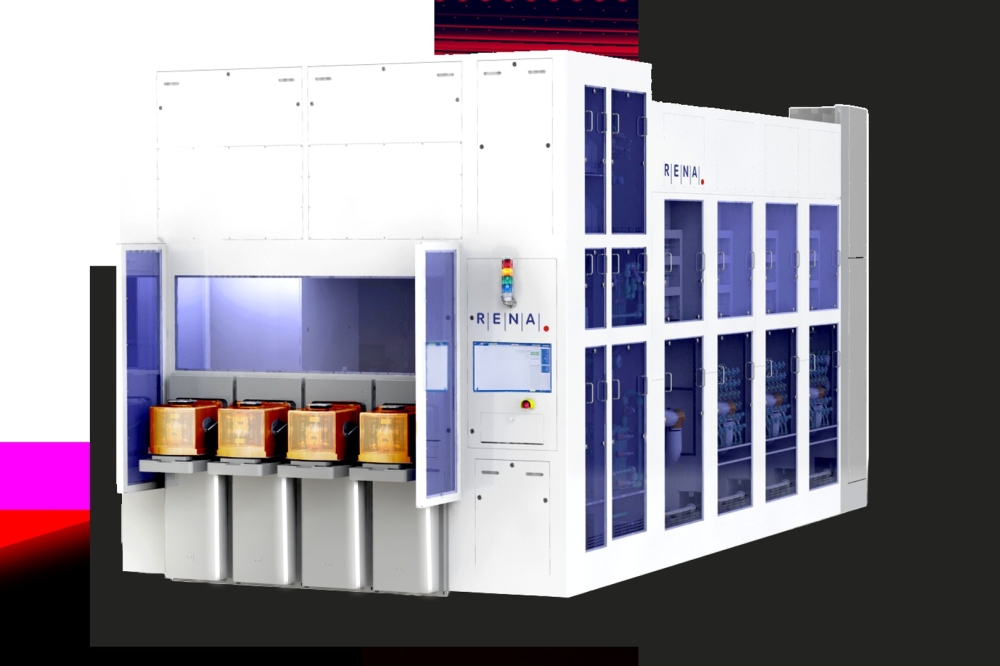

RENA Technologies has launched Vanguard, a fully automated single- wafer platform designed for wet chemical cleaning, etching, and drying of 200mm and 300mm wafers.

Vanguard is purpose-built to address the rising demands of next-generation semiconductor substrates and materials. Supporting 4 to 8 independent processing chambers within a compact footprint, the system is said to deliver high throughput without compromising cleanroom space.

Its features chemical cleaning and double-sided processing — handling up to five distinct chemistries — to minimise contamination, substrate damage, and defects, ensuring wafers meet stringent yield and quality requirements.

"With the launch of our new semiconductor wet processing platform, we are entering a new aera in precision, efficiency, and reliability for advanced chip manufacturing. This machine embodies our commitment to innovation — delivering not only superior process control but also the flexibility our customers need to stay ahead in a rapidly evolving industry. It represents a decisive step in enabling the next generation of semiconductor technologies for both high-volume manufacturing lines and R&D fabs." Said Peter Schneidewind, CEO of RENA Technologies.

Vanguard’s modular architecture grows with customer needs. Fabs can easily adjust chamber count and process configurations to match evolving requirements, from R&D to high-volume production.

The platform integrates internal chemistry preparation for precise formulation control, ensuring consistent process delivery and minimising chemical consumption. This reduces operating costs and environmental impact—key considerations for sustainable fabs.

Serviceability is also built-in: each chamber operates independently, allowing maintenance without halting production. Combined with AI-assisted process control, and the digital service platform RENA Connect Hub, customers gain maximum uptime and efficiency.

With its digital twin simulation, customers can model system integration, test interfaces, and even simulate throughput with real process data—well before installation. Training and upgrades can be conducted seamlessly during live production.