Aluminium treatment boosts efficiency of green miniLEDs

Researchers from China have increased the optical efficiency of green LEDs by employing aluminium treatment during the growth of quantum wells.

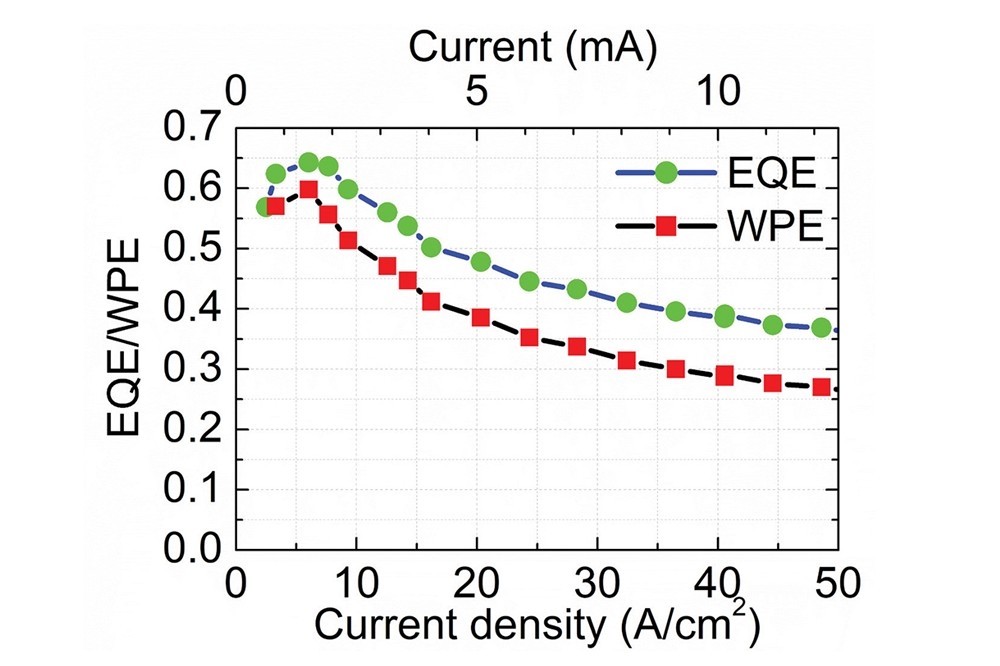

The devices produced by the collaboration – a partnership between Yancheng Teachers University, the Institute of Semiconductors, Xiamen University, and Yangzhou Zhongke Semiconductor Lighting – have a peak external quantum efficiency (EQE) of 65 percent and a wall-plug efficiency of 60 percent.

According to team spokesman Hongjian Li from Xiamen University, these efficiencies enable the team’s miniLEDs to be attractive candidates for deployment in displays.

Green LEDs are not as efficient as their blue cousins, due to: piezoelectric fields, which pull apart electrons and holes and hamper light emission; and the need for a higher indium content in the wells, which leads to a higher density of light-quenching defects.

Due to these drawbacks, visible LEDs suffer from a ‘green gap’. It is a significant issue that the global research community has tried to address with a number of novel approaches, including the use of non-polar and semi-polar structures, nanowires, quantum dots, staggered and graded quantum wells, and shallow quantum-well designs.

Significant successes to date by other Chinese collaborations are a peak EQE of 53.3 percent at 527 nm, as well as a peak EQE of 55.6 percent at 525 nm for a GaN-on-silicon LED.

Li and co-workers have exceeded these EQE values with a device that’s grown on a patterned sapphire substrate and features aluminium-treatment, applied between the growth of the InGaN quantum wells and GaN barriers.

After loading the sapphire substrate into the MOCVD reactor, the team deposited a 30 nm-thick nucleation layer at a low temperature, followed by a stack of epilayers.

After growing each InGaN quantum well at 760 °C, the team introduced trimethylaluminium into the chamber for 10s with a flow rate of 8 mmol min-1 while maintaining ammonia flow and stopping the flow of indium and gallium sources. Growth of GaN barriers followed, after the temperature had been ramped to 940 °C.

Processing epiwafers into flip-chip miniLEDs with a mesa area of 0.025 mm2 involved: inductively coupled plasma etching to expose the n-type contact layer; electron-beam deposition and patterning of ITO and Cr/Al/Cr/Pt/Au layers on the p-GaN and n-GaN surfaces, respectively; addition of a distributed Bragg reflector, formed from alternating layers of Ta2O5 and SiO2; and the formation of Cr/Al/Ni/Al/Ti/Pt/Au contact pads.

X-ray spectroscopy of the epistructure revealed an AlGaN layer around just 0.5 nm-thick on top of the InGaN quantum wells. According to this metrology technique, the gallium mole fraction in this AlGaN layer is a very high, with an aluminium content around just 10 percent, due to atom over-reactions in the MOCVD chamber.

The team also studied its material with high-resolution transmission electron microscopy, finding just three ‘V’ pits in a 3 mm-width area. This observation is claimed to indicate a very low defect density in the active region.

Evidence of superior radiative recombination arising from the aluminium-treatment comes from time-resolved photoluminescence. Exciton lifetime in the LED structure without this treatment is 75 ns, compared with 17 ns for the improved active region. Meanwhile, atomic force microscopy on the surface of the quantum wells has determined that aluminium treatment decreases the size of the pits and reduces surface roughness from 4.8 nm to 1.7 nm, enabling step-flow growth.

Another benefit of the aluminium treatment is that it reduces the blue shift in peak wavelength with current density.

For the device with aluminium treatment, the peak EQE and wall-plug efficiency occur at a current density of around 5 A cm-2, and fall to 47.8 percent and 38.5 percent, respectively, when driven at 20 A cm-2.

“We believe that Auger recombination is the main cause for the efficiency droop in InGaN green LEDs,” says Li, who explains that the collaboration’s next goal is to produce devices operating at longer wavelengths, such as those emitting in the red.

Pictured above: Droop, attributed to Auger recombination, leads to a decline in the efficiency of green LEDs produced with an aluminium treatment.

Reference

Ref: Y. Zhao et al. Appl. Phys. Express 18 082001 (2025)