AccuStrata Introduces new In-Situ Monitoring System

AtOMS tool is first to provide in-situ information about concentrations of individual chemical elements on the substrate

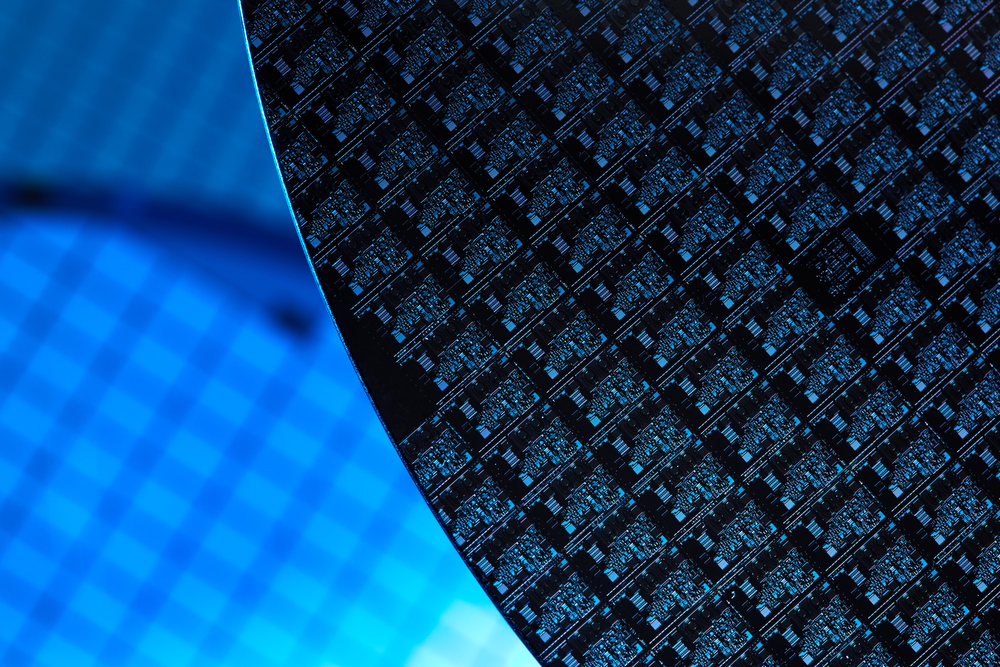

Process control firm Accustrata, based in Rockville, USA, has introduced a new system for in-situ monitoring of thin films during PVD, that is designed to overcome the limitations of existing solutions.

Called AtOMS, it is a combined atomic absorption (AAS) and broadband optical emission system (OES) for monitoring element flux during thin film deposition. It can monitor up to four elements simultaneously and supports up four four probe beams for monitoring different areas over the substrate or separate chambers.

The major pain point for the PVD thin film industry today stems from the inability of current technologies to monitor and control, in real time, critical qualities that are increasingly essential for next generation thin film products. Materials such as compound semiconductors and alloys, optically opaque materials, patterned thin films, films with thickness below 2-3 nm or very thick multilayers represent a significant process control challenge for legacy control systems. As technological innovations require more complex 3D and nanostructures, metamaterials, high entropy alloys, and more, AtOMS is poised to overcome many limitations of legacy process control solutions and enable the manufacturing of next-generation thin films.

Currently, no other technology can provide in situ information about the concentration of the individual chemical elements on the substrate, where the compound material grows during deposition. The resulting film composition and its spatial uniformity over the substrate remains uncontrolled or inaccurately controlled.

According to Accustrata, AtOMS is uniquely capable of monitoring the material flux and deposition rate very close to the substrate of up to four individual chemical elements in the deposition plume, the optical emission of multiple particles and radicals in the plasma, and other parameters needed for in situ control of the chemical composition and uniformity. It uses multiple probe beams to monitor large plasma areas in the vacuum chambers close to the substrate or the source for feedback control. AtOMS is also a simple solution for monitoring non-transparent materials, very thin films (1-10 angstroms), very thick coatings and very high thin film deposition/etching rates.

AtOMS was developed under a US Department of Energy (DoE) Small Business Innovation Research (SBIR) program that is currently in its 5th project year as Phase IIB. It is deployed for deposition control of X-Ray and EUVL mirrors as well as for monitoring and control of epitaxial processes.

The system allows monitoring of momentary deposition rates with accuracy below 0.01A/s and composition accuracy of 0.005 atomic percent (element specific). The fiber-optics based design provides for easy retrofitting to a wide variety of vacuum chambers. It has been successfully beta-tested at two DOE sites and deployed at a large commercial MBE house.

Several improvements are planned for the near future. The combination of multi-element AAS with broadband OES will be validated for predictive end-point detection during ion etching where legacy plasma OES technology lacks accuracy. The system will also be validated for control of film thickness and uniformity over large area substrates, substrates with complex shapes, and monitoring of extremely thin pre-engineered interlayers between individual films in the X-Ray and EUVL mirrors.

More about the system can be found here .