Photon Design to exhibit QD simulation tool

Photon Design, a UK developer of photonic simulation CAD tools, is showing the results from its upcoming quantum dot software module at SPIE Photonics West in San Fransisco (28th to 30th January 2025).

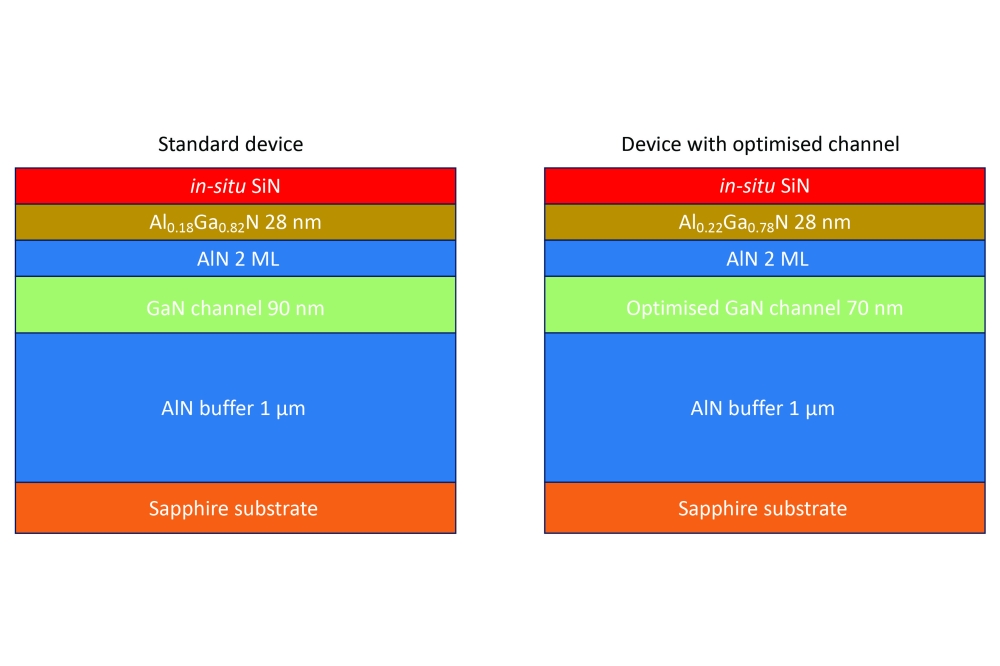

The module, which is being added to the company's HAROLD laser simulator, will allow simulation of gain and absorption spectra from epitaxy structures with multiple quantum dot layers using an eight band k.p model and a full 3D stress-strain model.

The module was developed and validated in collaboration with Cardiff University, one of the UK’s leaders in compound semiconductor photonics.

Dominic Gallagher, CEO and founder of Photon Design said: “HAROLD is a design tool for modelling the epitaxy layer composition of Fabry-Perot and VCSEL quantum well lasers. The new HAROLD quantum dot module enables rapid, virtual prototyping and performance verification of the absorption and gain spectra of the quantum dot layers, down to the sizes and distribution of the dots in the epitaxy. This will help inform and improve the supplier’s manufacturing process, linking real test results with the simulation model.”

HAROLD and the quantum dot module sit within Photon Design’s CAD environment; a library of simulation tools for designing passive components (such as ring resonators, surface grating vouplers and AWGs) up to entire active photonic integrated circuits.