Flexible perovskite/CIGS tech reaches 23.64% efficiency

The Korea Institute of Energy Research (KIER) has successfully developed ultra-lightweight flexible perovskite/CIGS tandem solar cells and achieved a power conversion efficiency of 23.64 percent. The research was published in the March 2025 issue of the journal Joule.

This is believed to be the world’s highest efficiency for flexible perovskite/CIGS tandem solar cells reported to date.

Currently, perovskite/silicon tandem solar cells have achieved efficiencies as high as 34.6 percent. However, their heavy weight and susceptibility to physical damage limit their application in fields where lightness and adaptability are critical, such as in automobiles, aircraft, and satellites.

Flexible thin-film perovskite/CIGS tandem solar could be a better option being extremely lightweight and flexible, making them well-suited for use on curved surfaces such as buildings, vehicles, and aircraft. However, their lower efficiency and greater manufacturing complexity compared to perovskite/silicon tandem solar cells have posed barriers to commercialisation.

To enhance the manufacturability, flexibility, and lightness of tandem solar cells, the KIER research team developed a simple lift-off process and identified the underlying mechanisms behind the performance improvement. As a result, the fabricated perovskite/CIGS tandem solar cell achieved a power conversion efficiency of 23.64 percent, representing the highest recorded efficiency among flexible perovskite/CIGS tandem solar cells reported to date.

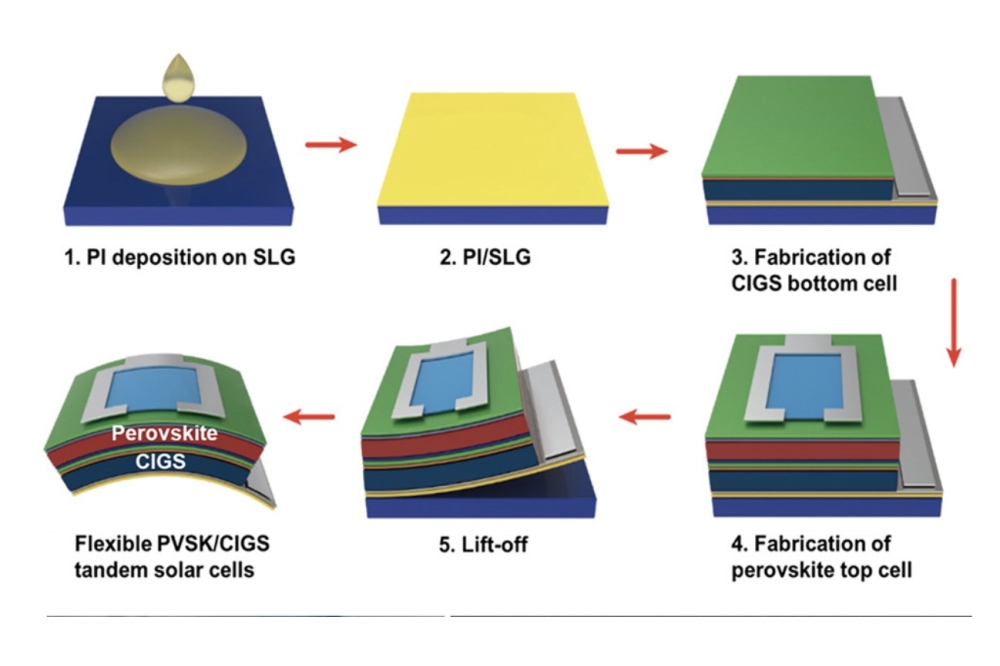

The lift-off process (pictured above) developed by the research team involves coating a polyimide (PI) layer onto a soda lime glass (SLG) substrate, fabricating the perovskite/CIGS tandem solar cell on top of it, and then separating it from the glass. Unlike conventional methods that use flexible polyimide film directly as the substrate, this approach utilises rigid glass as a supporting base, allowing for more stable fabrication of the solar cells. The use of a flat, rigid glass substrate also ensures uniform layer deposition, leading to improved device performance and higher reproducibility.

The research team also identified a method to enhance performance by reducing defects in the solar cell. During the fabrication process, alkali metal elements such as potassium diffuse from the glass substrate into the CIGS light-absorbing layer. Excessive diffusion of potassium can create defects within the absorber layer that hinder charge transport, ultimately degrading the performances of the solar cells. However, until now, no technology had been reported that effectively suppresses the diffusion of potassium to an optimal level.

Using computational science, the research team predicted that the polyimide layer coated on the glass substrate could suppress potassium diffusion. When applied to the solar cell fabrication process, this approach effectively reduced defects in the CIGS light-absorbing layer. As a result, the fabricated device achieved a power conversion efficiency of 23.64 percent, significantly exceeding the previous record of 18.1 percent for flexible perovskite/CIGS tandem solar cells.

In addition, to verify the durability of the fabricated CIGS solar cells, the research team measured the mechanical properties of the materials and analyzed the stress applied during bending through simulations. After conducting 100,000 bending cycles, the solar cells maintained 97.7 percent of their initial efficiency, demonstrating excellent durability.

Inyoung Jeong, who led the study, stated, “This research is a key achievement that demonstrates the commercial potential of next-generation high-efficiency solar cell technology with flexibility and lightness,” adding, “It serves as an important milestone toward realising ultralight, flexible solar cells with 30 percent efficiency in the future.”

Kihwan Kim, principal investigator of the study, stated, “The power-to-weight ratio of the fabricated solar cell is approximately ten times higher than that of perovskite/silicon tandem solar cells, making it highly promising for applications in fields that require ultralight solar modules, such as building exteriors, vehicles, and aerospace.” He added, “By advancing large-area fabrication processes and improving stability, we aim to strengthen the competitiveness of related industries and significantly contribute to the expansion of renewable energy adoption.”