MicroLEDs: Eliminating etching

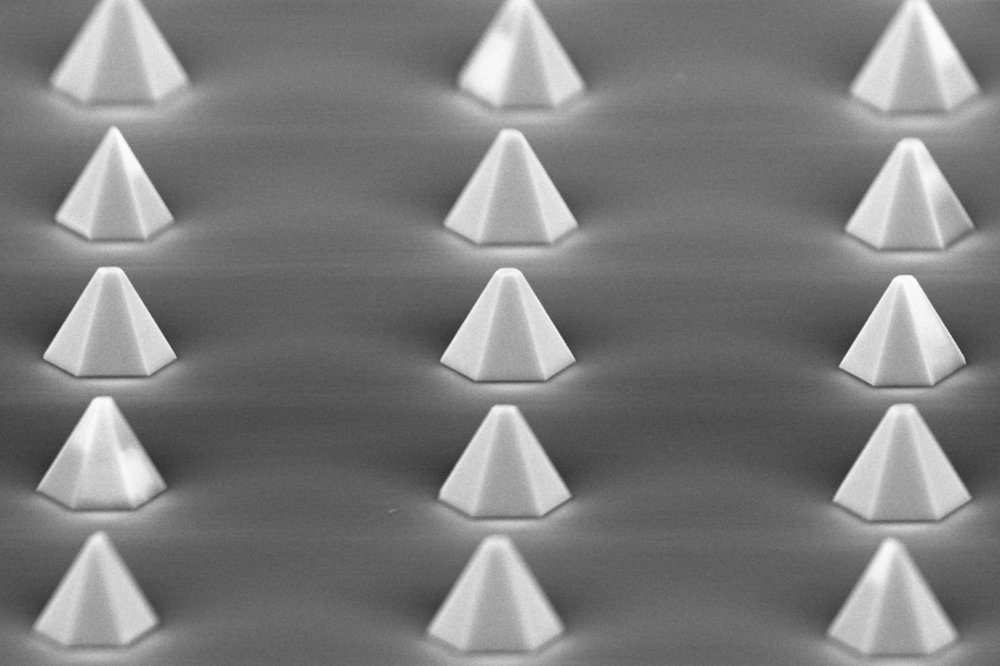

Pyramidal microLEDs on patterned SiC deliver a great performance, even when their dimensions approach the nanoscale.

BY RICHARD STEVENSON, EDITOR, CS MAGAZINE

Ideally, when producing compound semiconductor devices, every process adds functionality without introducing compromise. For example, the addition of an anti-reflection coating should increase the efficiency of a multi-junction solar cell without limiting its lifetime; and when mirrors are added to a laser, they should boost reflectivity without introducing light-quenching defects.

On the whole, processing epiwafers into devices follows this formula, with a succession of positive steps creating a high-performance chip. But there is an exception: the microLED. When crafting such a smaller emitter, its dimensions are typically defined by etching, a step that creates imperfections, including dangling bonds that drag down efficiency. It’s possible to restore this device’s performance through passivation, using techniques such as plasma-enhanced CVD and atomic layer deposition. But wouldn't it be better to never damage these miniature marvels, rather than having to repair them?

Pursuing this attractive approach with vigour is the Swedish start-up Polar Light Technologies. This spin out of Per Olof Holtz’s group at Linköping University has been gathering pace this year as it looks to increase the spectral coverage of its devices, engage with other companies, and win further funding to support its shift from development to production.

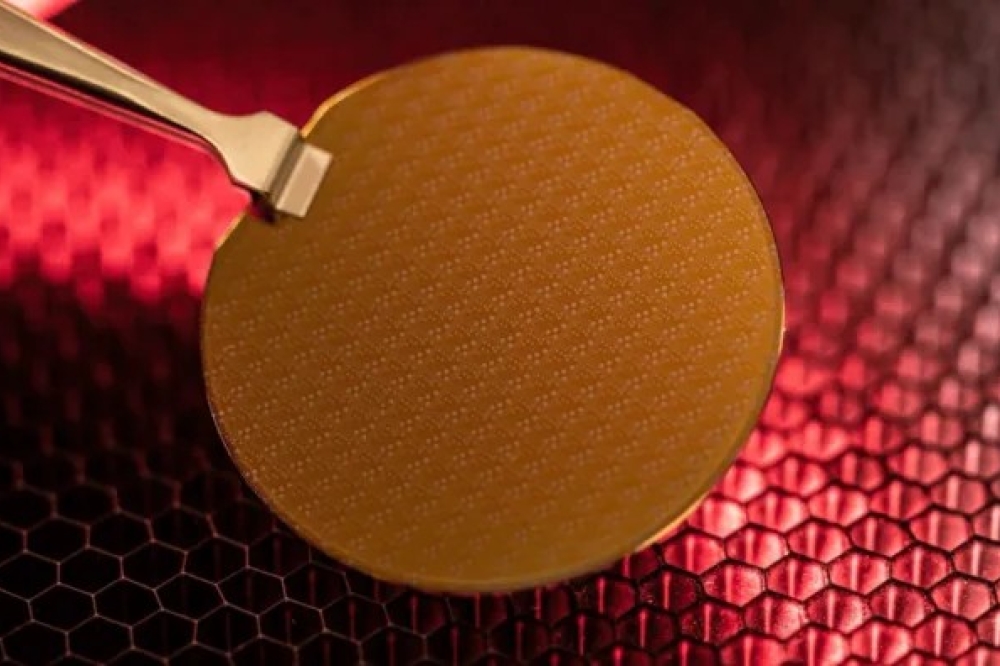

The core technology of Polar Light Technologies is its pyramidal LEDs, formed by growth of GaN-based structures on patterned SiC substrates by MOCVD.

According to the company’s Chief Product Officer and co-founder, Ivan Martinovic, the initial target market for these novel emitters is the light source for augmented-reality headsets. Martinovic views his company’s technology as a competitive candidate for making monochrome panels in products made by the likes of Jade Bird Display, with full-colour images formed with an optical system that combines the output of red, green and blue sources.

Looking further ahead, Martinovic expects microLEDs, including those he is helping to pioneer, to penetrate the automotive industry, due to their high level of robustness. MicroLEDs may also take market share from OLEDs in the smartwatch sector, where they promise to enable a battery life of several days.

For the first of these target markets, augmented-reality headsets, displays should have a pixel size approaching two microns, says Martinovic. “The subpixel should be even smaller, and with the spacing, it's a submicron game at that point.”

As well as increasing the fidelity for the user of the headset, microLEDs that are small enough to meet this requirement deliver cost benefits.

“Whether it's for micro-displays, where you monolithically integrate onto silicon, or mass transfer for large-area displays, you want to have really, really small LEDs,” argues Martinovic. “You can't have five- or ten-micron microLEDs, even for big panel displays. You will use too much epi for your display.”

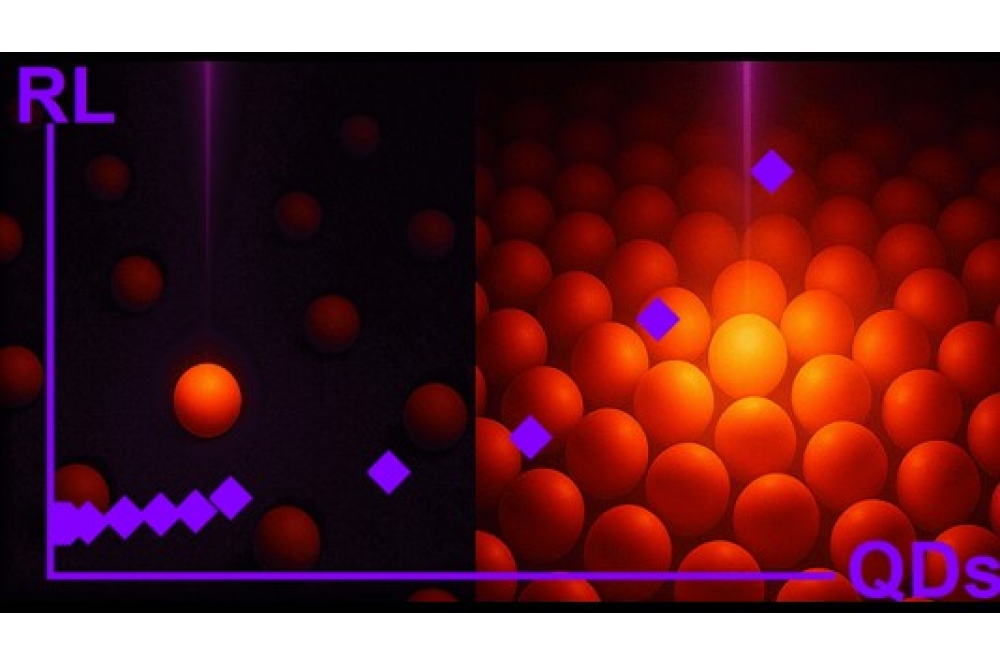

Polar Light Technologies has produced blue and green pyramidal microLEDs, and is working on red-emitting variants

Note that it’s not possible to produce conventional microLEDs as small as this that deliver high performance. “You're in the area where damage caused by the etching is getting so out of hand that it's almost not controllable anymore,” says Martinovic.

While the pyramidal microLEDs excel at such small dimensions, they do incur a substrate cost penalty compared with their more conventional LEDs, due to the use of SiC. However, this expense is overshadowed by etching-related issues, argues Martinovic, who points out that the size of SiC substrates is increasing while their price is staying the same. “So in that case, you can say that the price is coming down.”

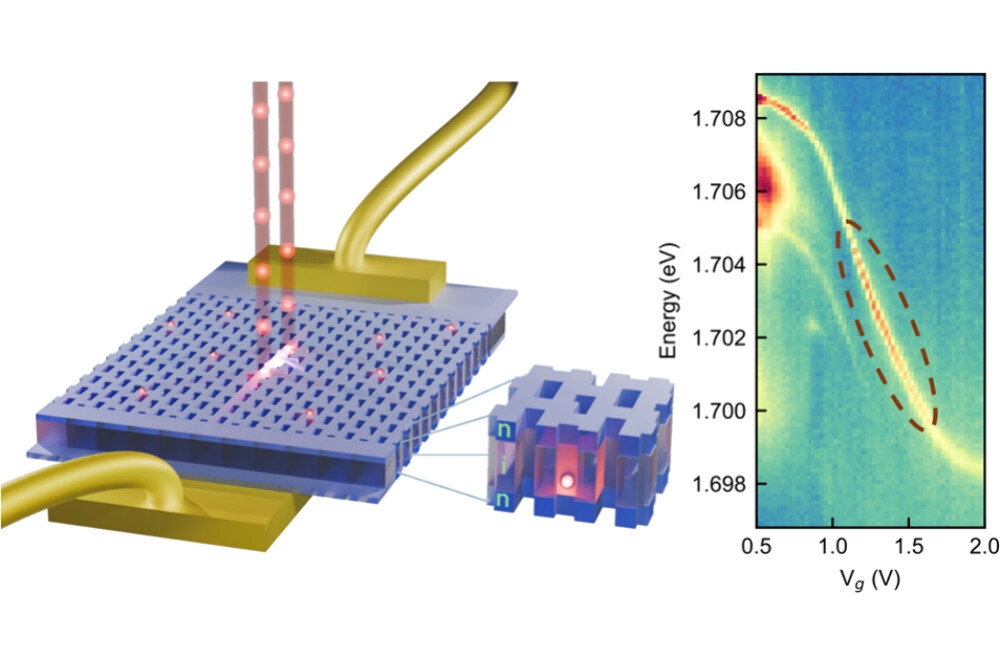

The pyramidal shape of Polar Light Technologies’ microLEDs delivers a number of benefits, including an increase in the light extraction efficiency and an emission profile that leads to better utilisation of light.

So far, demonstrations of the company’s technology have focused on devices emitting in the blue and green, but evidence of capability in the red is in the pipeline.

Propelling the emission of GaN-based LEDs to the red is not easy. Success requires increasing the indium content in the quantum wells, but that leads to significant strain that spawns non-radiative defects. Switching to wider wells can alleviate this strain, but at the expense of a reduction in the recombination efficiency, due to a reduction in overlap of electrons and holes, which are pulled towards opposite edges of the wells by internal electric fields.

These problems diminish with pyramidal LEDs. Due to their geometry, they are semi-polar and thus enjoy a reduction in the strength of the internal electric fields that hamper radiative recombination.

Polar Light Technologies has been honing its pyramidal microLEDs over many years. The company formed in 2014, with much initial effort devoted to research and filing patents.

Funding for the start-up, which comes from a number of local venture capital firms, only began in 2021.

“We've gathered a really nice network of Swedish and Nordic VCs. We've chosen to focus on them. We want to keep it here,” says Martinovic, who is now working on a “medium-sized” round that is slated to close at the end of this year.

“At the end of next year, we're gearing up to bring in a more serious level of funding - let's say the A round for Polar Light.”

So far, the company has carried out all the process steps in house, including the fabrication of the silicon chips that are used to drive the microLEDs.

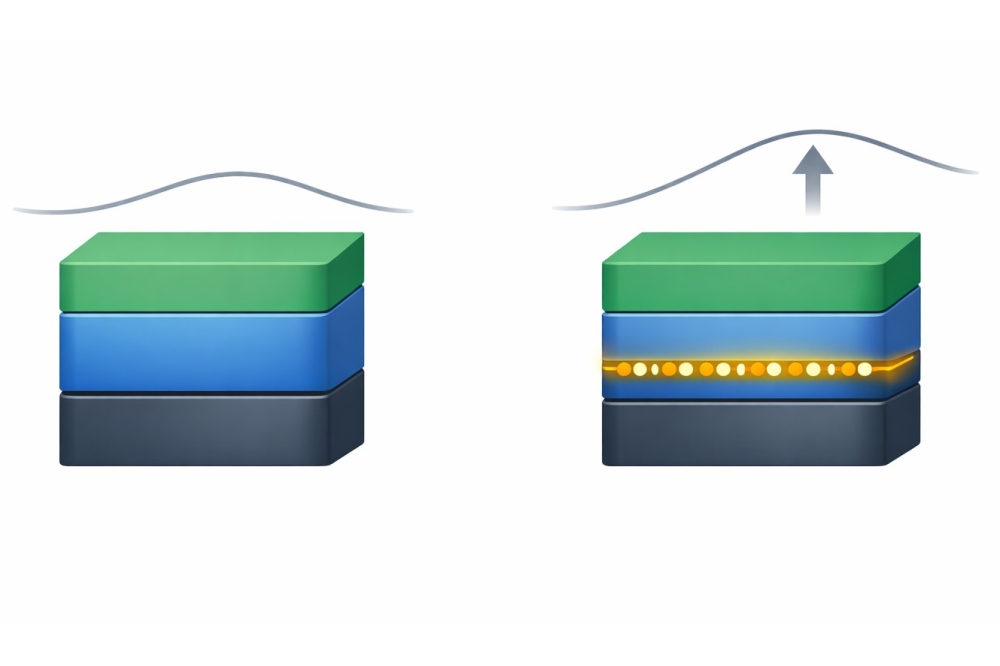

“We're using a cold bonding approach to hybridise, to put together gallium nitride LEDs with silicon CMOS,” says Martinovic. He explains that a bonding approach involving heating is not permitted, because slight differences in thermal expansion coefficients would lead to a misalignment that’s exceeds the pitch of the display.

This in-house modus operandi is unlikely to continue, as Martinovic and his colleagues are looking to start working with partners. “We're much more active right now and much more open to collaborations than we've ever been. That's part of that direction of going towards product. We're not going to do this ourselves.”

It’s a good mover, as more collaboration will be key to the driving success of microLEDs in a number of displays, where bright, miniature emitters that are free from etching look to shine.