IDTechEx examines status of 800V for EVs

The automotive industry is converging on 800V platforms for battery electric vehicles (BEVs), when earlier generations of vehicle were 400V.

While 400V will certainly have a part to play in the next decade, the advantages of 800V platforms are undeniable, and in most cases worth the re-engineering of the powertrain to accommodate this.

IDTechEx examines these trends in its new report, 'Power Electronics for Electric Vehicles 2026-2036: Technologies, Markets, and Forecasts', and uses them to forecast the adoption of wide bandgap semiconductors SiC and GaN, as well as the entire power electronics market for electric vehicles (EV).

Moving to a higher voltage means that the battery can charge at greater power while using less current. For consumers that want charging to be as quick as refueling an internal combustion engine (ICE) vehicle, 800V vehicles can deliver greater average and peak rates of power. While this is generally the case, other parameters in the vehicle and also in the charger will determine the actual charging speed.

Finally, since less current runs through the wiring harnesses in the vehicle, the diameter of the wiring harness can be significantly reduced. Copper is heavy and expensive, so a theoretical halving of the wiring harness diameter (excluding insulation and cooling requirements) delivers a compounded cost and weight saving. Even though BEVs are much more efficient than ICE vehicles, squeezing out extra efficiency at lower cost is beneficial to the consumer, but also to the OEM, many of which have struggled with the profitability of their BEVs.

Different ways to achieve 400V to 800V compatibility

One glaring issue accompanies 800V platform EVs: the majority of DC chargers in the world are 400V, meaning that there needs to be an onboard system to convert the 400V DC from the charger to 800V DC to charge the high voltage battery.

Without such a system, the majority of DC chargers cannot be used. Mercedes controversially did not include an 800V booster in its announcement for the Mercedes CLA EV earlier in 2025, although this has since been reversed.

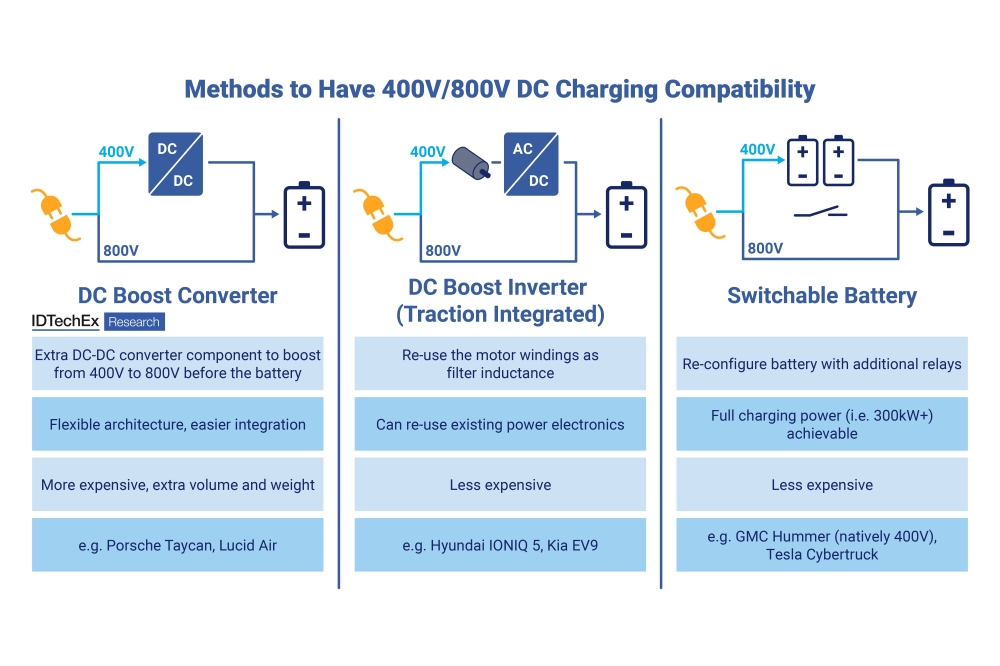

IDTechEx has identified three key ways to achieve 400V to 800V charging compatibility, each with its own advantages and disadvantages. While each system is complex, IDTechEx has found that battery switching, DC boost converters, and traction integrated onboard chargers are the three main approaches from OEMs and tier-one suppliers to achieve 800V compatibility.

Boost converters are the simplest method, whereby an extra DC-DC converter is installed onto the vehicle to boost the voltage from 400V to 800V before feeding into the high voltage battery. While this is simple, it is also costly to add this extra unit, especially when space in a vehicle is limited to begin with. This is the method used in the Porsche Taycan.

By switching the configuration of cells in charging, the battery pack can be charged as a mix of series and parallel connections to match the incoming voltage from the DC charger. The GMC Hummer and Tesla Cybertruck run variants of this technique to ensure charging compatibility.

Finally, traction integrated onboard chargers are a unique way to boost the voltage without the need for a separate DC-DC converter. The windings in the electric motor act as filter inductance, and are used to boost the voltage of the incoming DC from the charger without requiring a separate DC-DC converter unit. This is the approach used by Hyundai and Kia, and multiple tier-one suppliers have similar methods to boost voltage.