Lynred launches advanced thermal imaging modules

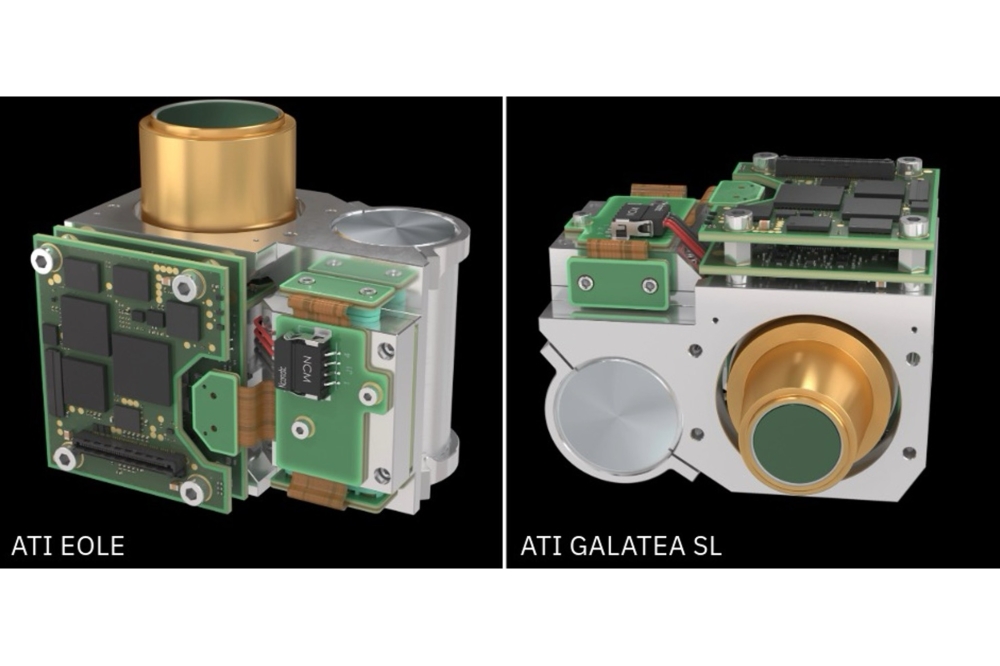

Lynred, a provider of infrared sensors, has announces the launch of ATI EOLE and ATI GALATEA SL, two III-V-based Advanced Thermal Imaging (ATI) modules that Lynred has designed to simplify integration of high-performance IR sensing in vision systems.

ATI EOLE is suited for gas detection, delivering the thermal sensitivity that transmission system or distribution system operators in the oil & gas sector require to better comply with new regulations for tightening methane leak monitoring.

ATI GALATEA SL targets fast-evolving Unmanned Aerial Vehicles (UAVs), to assist gimbal manufacturers in accelerating time to market.

Both ATI EOLE and ATI GALATEA SL modules produce a high-quality video output that is ready for immediate analysis by users.

“Lynred is thrilled to launch its brand-new suite of cooled infrared sensor-based ATI modules. These products greatly ease and accelerate the integration of cooled infrared technology for newcomers to thermal imaging or for more experienced customers wishing to quickly go to market,” said Hervé Bouaziz, executive president of Lynred. “There has been growing interest in ATI EOLE and ATI GALATEA due to their high-performance and compactness, combined with this ready-to-use concept.”

Each ATI module comes with an additional processing board, stacked onto the proximity board. This new board is light (15 grams), small and the same form factor as the proximity board. Both modules have a low power consumption, adding only 1Wdc compared to the power consumed by a sensor.

ATI EOLE operates in the 3.2-3.55µm spectral band and has a high thermal sensitivity, allowing it to detect a leak rate as low as 1.4g/h. ATI GALATEA SL operates in the 3.6-4.2µm, mid-wave blue band, which makes it suitable for long-range applications such as tactical UAVs.

Both modules are designed with Lynred’s PlugUp standardised platform that maintains the same form factor and identical interfaces (mechanical, optical and electrical) across designs. “This means vision system integrators can switch between camera types (OGI or Surveillance) with very little effort,” said Adrien Bertrand, product manager at Lynred.