Forvia Hella to use CoolSiC for next generation charging

Forvia Hella, an international automotive supplier, has selected Infineon's new CoolSiC automotive MOSFET 1200 V for its next generation 800 V DCDC charging solution.

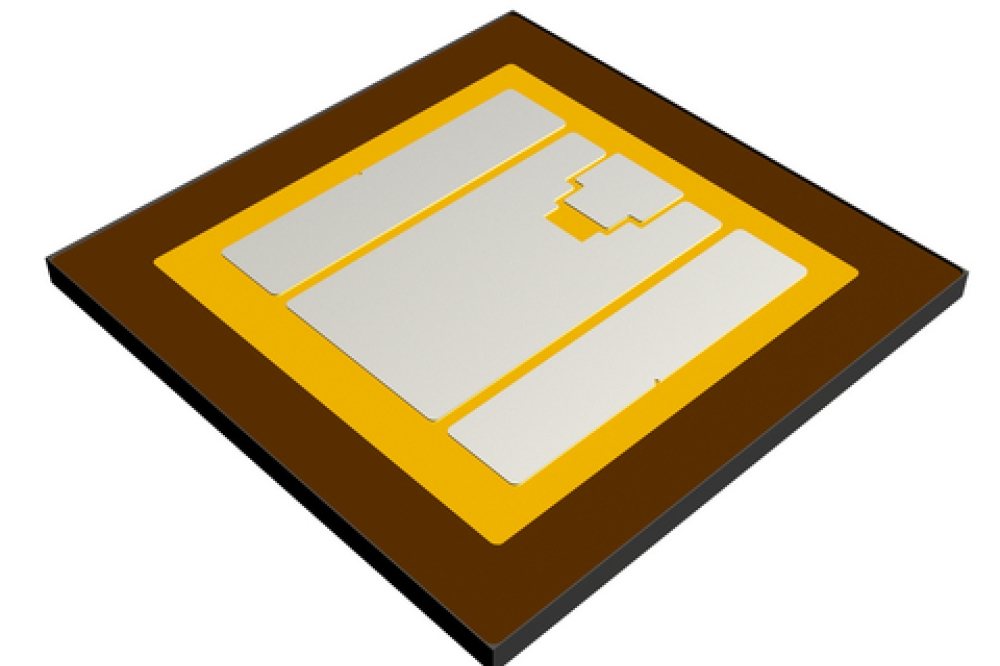

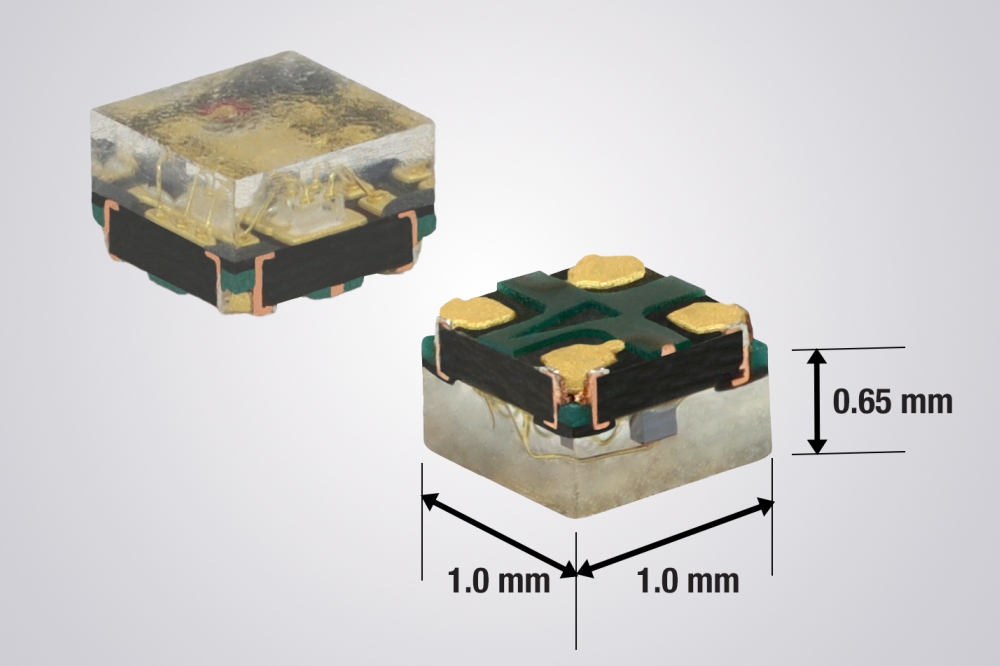

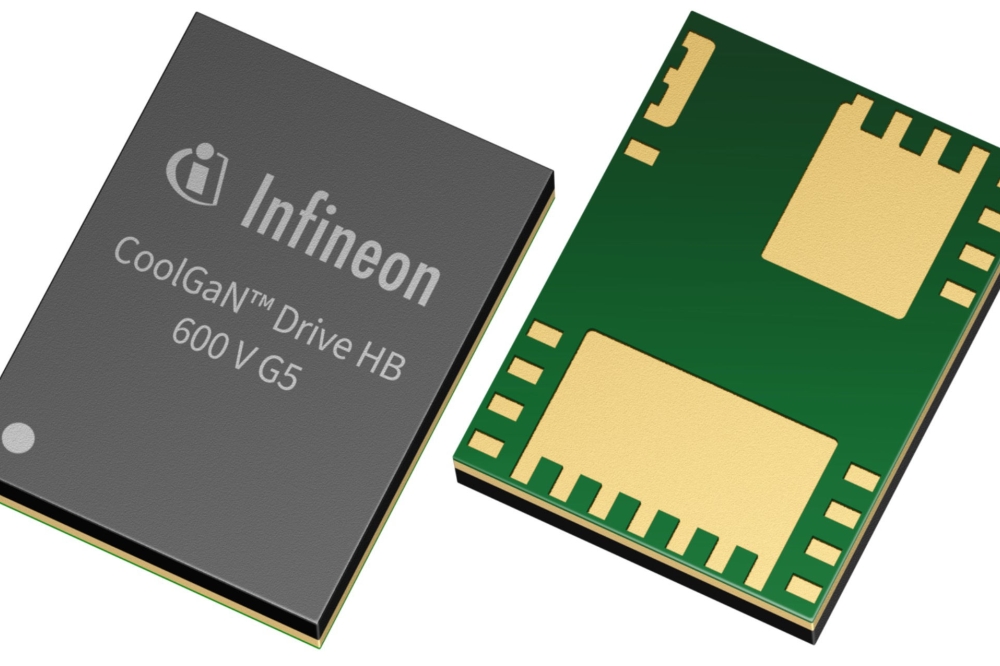

Designed for on-board charger and DCDC applications in 800 V automotive architectures, Infineon's CoolSiC MOSFET comes in a Q-DPAK package. The device uses top-side cooling (TSC) technology, which enables excellent thermal performance, easier assembly and lower system costs.

Infineon's new automotive MOSFET in the Q-DPAK package is based on Gen1p technology and offers a drive voltage in the range of V GS(off)= 0 V and V GS(on)= 20 V. The 0 V turn-off enables unipolar gate control, which simplifies design by reducing the number of components in the PCB.

With a creepage distance of 4.8 mm, the package achieves an operating voltage of over 900 V without the need for additional insulation coating. Compared to backside cooling, the TSC technology ensures optimised PCB assembly, reducing parasitic effects and resulting in significantly lower leakage inductances. As a result, customers benefit from lower package parasitics and lower switching losses. Heat dissipation is further improved by diffusion soldering the chip with .XT technology, according to Infineon.

The CoolSiC Automotive MOSFET 1200 V in a Q-DPAK package is available now.