Horiba and Socrate Industrie partner on Vacuum Coating

Companies to work together on closed-loop process and control technologies that ensure coating thickness uniformity and composition

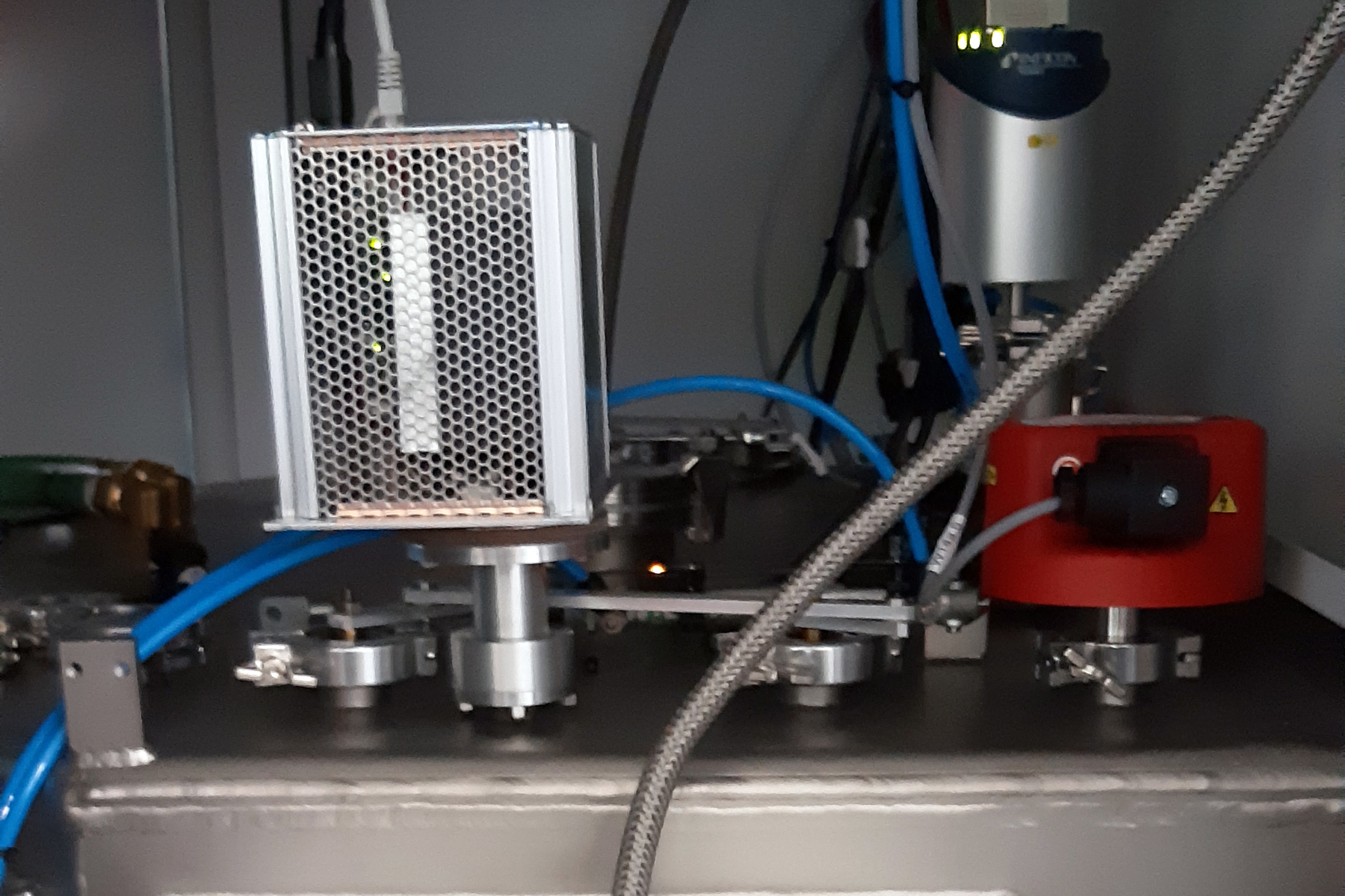

Horiba, a UK-based manufacturer of instruments and measurement systems, is collaborating with Socrate Industrie, a French firm, on process and control technologies that stand to improve quality and yield in vacuum coating applications that use PVD and plasma-enhanced chemical vapour deposition (PECVD).

Socrate Industrie supplies vacuum coating equipment for PVD and microwave enhanced plasma and hot-filament chemical vapour deposition and devices such as heaters and cathodes, as well as engineering services, into a variety of industrial sectors, including aerospace and medical.

Jean-Paul Gaston, product manager of Horiba Scientific, comments: “We’re working with Socrate Industrie on the development of a precision process control and analysis solution for metallic thin layer coating processes. The initial goal of the collaboration is to achieve optimum oxides coating stoichiometry and deposition rate, thickness and uniformity on 3D structures.”

Gaston goes on to explain that whilst the coating of flat surfaces, such as silicon wafers, still requires good control and monitoring to ensure coating quality in terms of uniformity and composition, deposition onto 3D objects is extremely challenging. He says: “Insufficient coating on the sides, for example, could reduce the end product’s efficiency and reduce its life. In contrast, more coating than necessary in other areas, say the top surface, is wasteful of materials and process gases. Our first task is to create a close loop control system that includes a mass flow controller and an optical spectrometer, both of which are Horiba products, for the stoichiometry monitoring of the coating.”

During PVD and PECVD, the light emission of the plasma is indicative of the materials present and the reactions taking place in the chamber. The inclusion of real-time signals representative of the chemical reactions taking place into the control of the materials and process gases going into the chamber provides a much-needed level of automation, will reduce waste and remove the risk of having to re-coat.

Gaston concludes: “There is a growing need for in-line / in-situ material analysis and characterisation in vacuum coating applications, but the metrology equipment needed is typically found in the scientific laboratory and was not designed for inclusion in manufacturing scenarios. Horiba, as an OEM of not only a wide range of industrial process control products, like mass flow controllers and residual gas analysers, but also world-leading scientific analysis equipment, is therefore the ideal partner to help create bespoke, well-engineered solutions.”