EPC announces ToF board with Ultra-fast eGaN FETs

Time-of-Flight demo board drives lasers with currents up to 28A with 1.2ns using automotive qualified eGaN technology

EPC has announced the availability of the EPC9144, a 15V, 28A high current pulsed laser diode driver demonstration board.

In time-of-flight systems, speed and accuracy of object detection is critical. As demonstrated on this board, the rapid transition capability of the AEC Q101-qualified EPC2216 provides power pulses to drive laser diodes, VCSELs or LEDs up to ten times faster than an equivalent MOSFET, in a small fraction of the area, energy, and cost

eGaN FETs and integrated circuits provide the high current pulses, extremely narrow pulse widths, and small size that make affordable, high performance lidar possible. The short pulse width lead to higher resolution, and the tiny size and low cost make eGaN FETs ideal for time-of-flight applications from automotive to industrial, healthcare to smart advertising, gaming, and security.

The EPC9144 ships with an interposer board. The interposer board is a collection of break-away 5 mm x 5 mm square interposer PCBs with footprints to accommodate different lasers, RF connectors, and a collection of other footprints designed for experimentation with different loads. The use of the interposers allows many different lasers or other loads to be mounted, allowing users to test the performance with the load requirements that are appropriate to their application.

EPC says the use of GaN is a critical factor making affordable, high performance lidar possible. Thus, the use of GaN components further expands the number of applications where increased accuracy is vital. These applications include self-driving cars and other time-of-flight applications such as facial recognition, warehouse automation, drones and topological mapping. The EPC9144 can also be used for applications requiring a ground-referenced eGaN FET; for example, in class E or similar circuits.

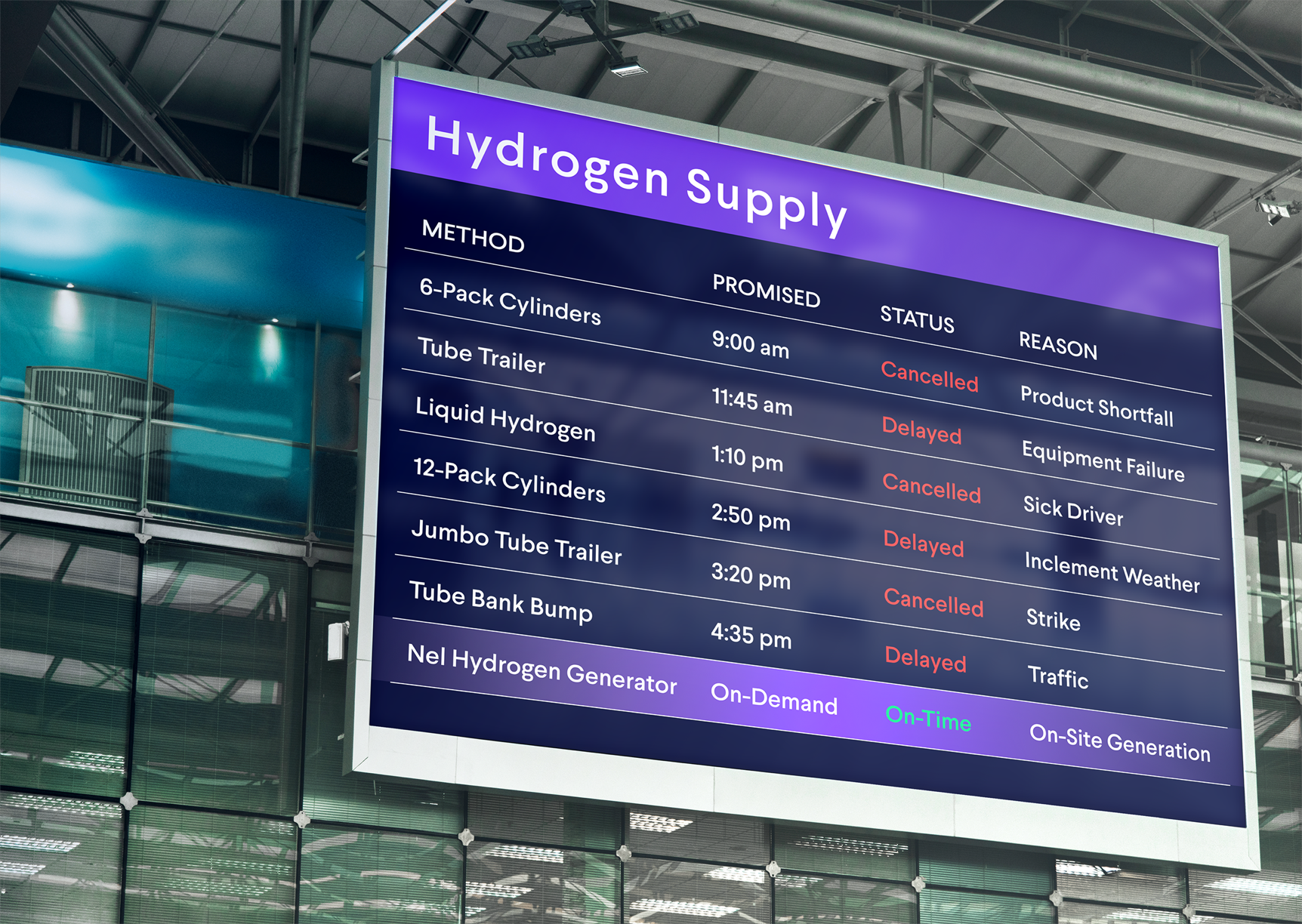

Secure Your Hydrogen Supply

A study supply of high-purity hydrogen is critical to semiconductor fabrication. Supply chain interruptions are challenging manufacturers, leading to production slowdowns and stoppages. On-site hydrogen generation offers a scalable alternative for new and existing fabs, freeing the operator from dependence on delivered gas.Plant managers understand the critical role that hydrogen plays in semiconductor fabrication. That important job includes crystal growth, carrier gas, wafer annealing, and in the emerging Extreme UV Lithography (EUV) that will enable new generations of devices. As the vast need for semiconductors grows across all sectors of world economies, so does the need for high-purity hydrogen.

Take control with Nel on-site hydrogen generation.

Read more

.jpeg)