Perovskite modules pass three critical stability tests

Results put perovskite thin film photovoltaic technology one step closer to commercialisation

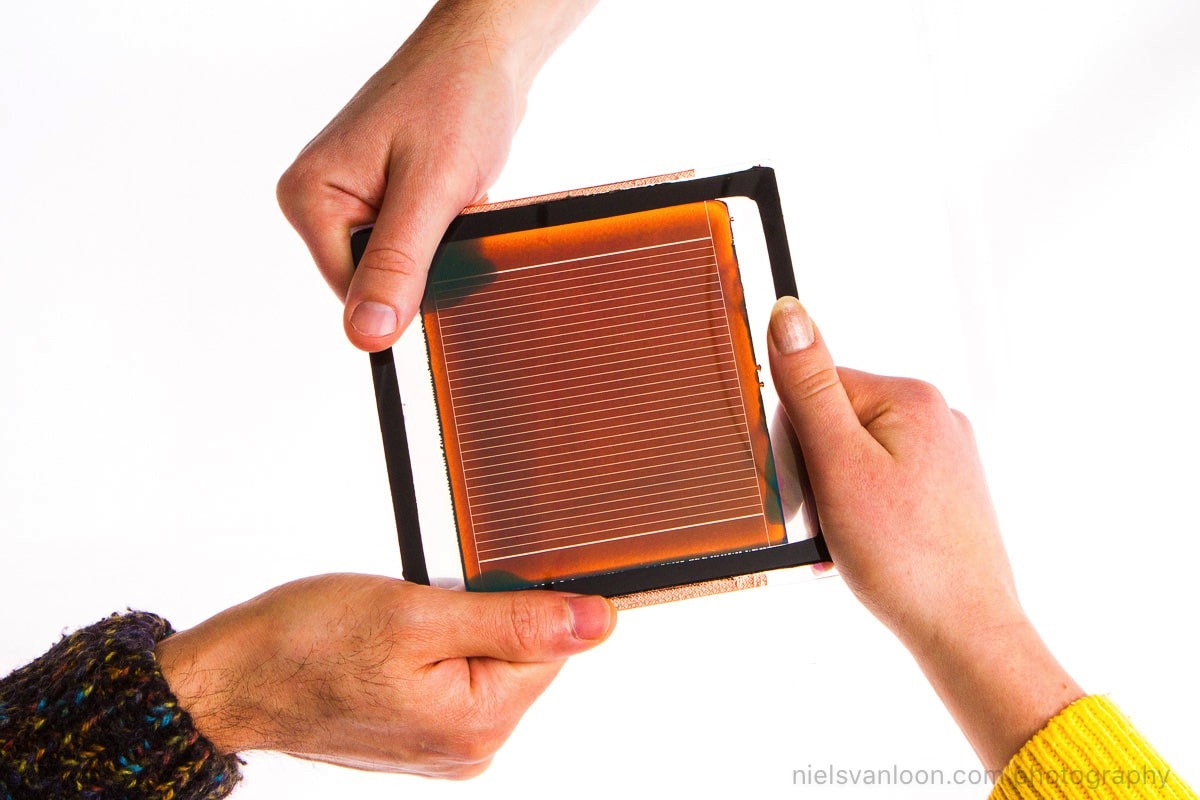

Solliance partners TNO, imec and the Eindhoven University of Technology, have demonstrated encapsulated perovskite solar modules fabricated using industrial processes that withstand three established lifetime tests, i.e. the light soak test, the damp-heat test and the thermal cycling test.

It is for the first time this milestone is passed with scaled perovskite solar modules prepared by research organisations.

Perovskite solar modules reported a decade ago, were only stable for minutes. By passing three tortuous ageing tests, Solliance and its industrial partners take a big step towards commercialisation of this novel solar technology.

The perovskite modules were prepared on 6x6 inch2 glass substrates using industrial processes (sputter coating, slot die coating, atomic layer deposition and laser based interconnection) and glass/glass encapsulated. The aperture area of these modules is 100 cm2. The initial performance of the modules is above 10 percent (aperture area efficiency).

The applied stress tests include 1000 hours continuous illumination at an intensity equal to one sun (light soak test); 1000 hours exposure to a high humidity (relative humidity of 85 percent) combined with exposure to a temperature of 85 degC (damp-heat test); 50 thermal cycles from -40 degC to 85 degC (thermal cycling test).

During the light soak test the performance increased in the first 100 hours after which the performance stabilised. After the damp-heat test the perovskite module performance retained 95 percent of its initial performance, thus within the restricted efficiency loss limit to achieve a successful damp-heat test. The thermal cycling test did not impose any efficiency loss, indicating the excellent stability of the processed modules and the encapsulation strategy to withstand these harsh conditions.

These encouraging results put the perovskite thin film photovoltaic technology one step closer to commercialisation, and puts Solliance in a leading position to achieve this target.

Perovskite solar cells and modules are nowadays widely acknowledged for their high efficiency values of up to 25.2 percent for the current latest record lab solar cell. In the future, it is hoped that perovskite modules can be integrated in windows, roof tiles, facades, roads, noise barriers, car roofs - and in fact in on any surface which receives light. Additionally, tandem solar modules consisting of a semitransparent perovskite module stacked on top of a conventional CIGS or silicon solar module can boost the overall efficiency to new record values.