Allos GaN-on-Si tech used for brain/machine interface

Collaboration with Toyohashi University of Technology develops nitride-based micro LED chips for novel in-vivo application

Hiroto Sekiguchi's team at Toyohashi University of Technology and Allos Semiconductors have collaborated to develop high efficiency nitride-based micro LED chips for novel in-vivo neutral application.

Since their evolution in the 1990s, nitride LEDs have made inroads into our daily lives, saving energy and enabling many new applications. They are known for their ubiquitous use in numerous illumination applications and the emerging micro LEDs are famous in particular for use in super large TVs or groundbreaking augmented reality displays as well as robust automotive displays.

Beyond the obvious illumination applications, nitride LEDs are also increasingly proving helpful in medical applications. For example, nitride LEDs emitting UV light are employed to fight viruses like COVID-19 by disinfecting surfaces.

Another example is Toyohashi University of Technology, Japan using nitride micro LED technology to build medical brain/machine interfaces. Hiroto Sekiguchi’s group has developed a neural probe to study brain functions using Allos’ micro LED epiwafer. To avoid brain damage, high-efficiency of micro LEDs are key in order to reduce harmful impact from heat coming from conversion losses. Furthermore, for micro LEDs extreme precision is needed.

GaN-on-Si to overcome manufacturing challenges

For this novel medical application, manufacturing challenges had to been overcome, where Allos’ GaN-on-Si technology plays a key role. In particular, it was important to integrate nitride LED technology with mature and precise silicon industry processes in order to achieve highest accuracy and reliability standards.

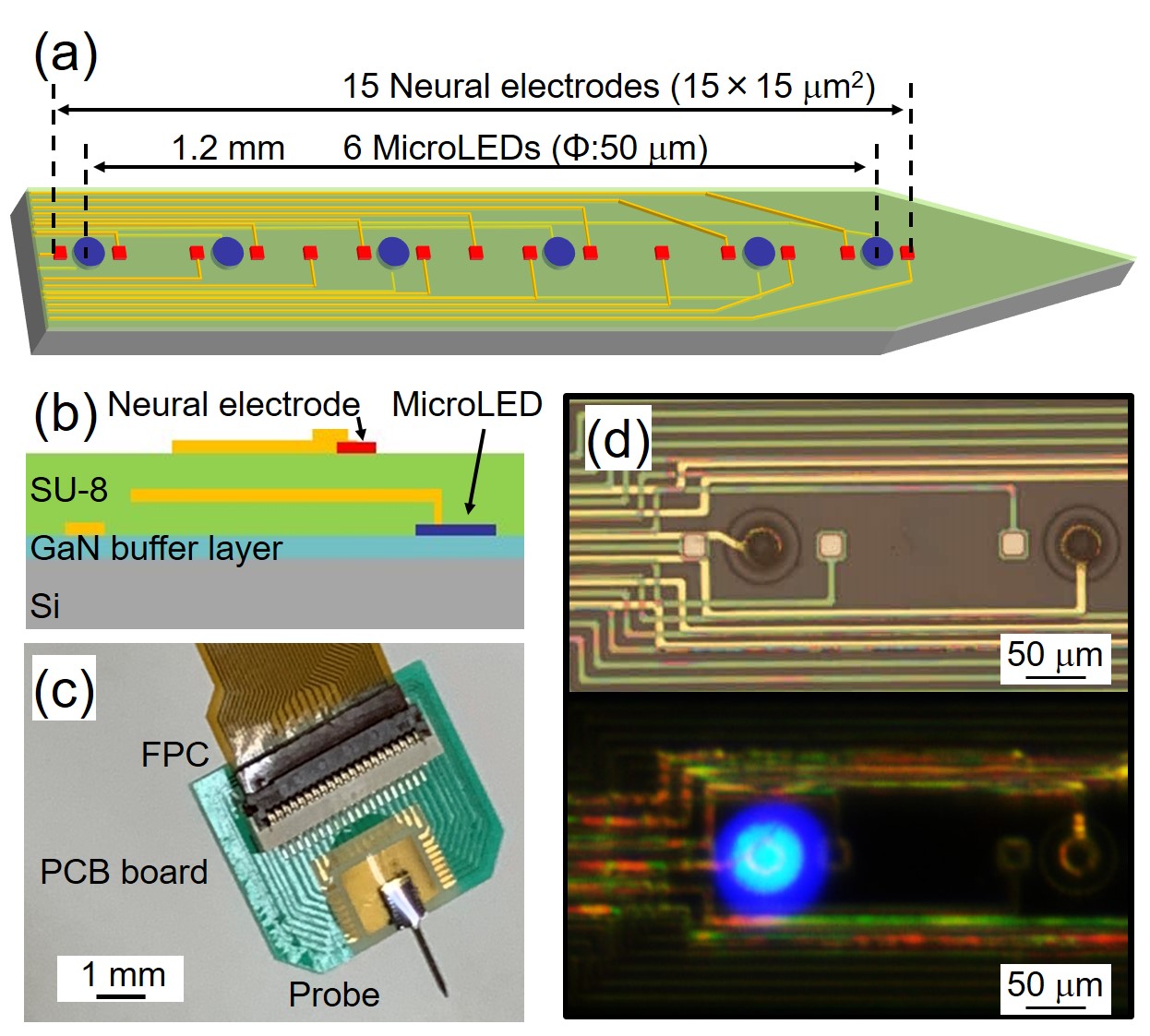

Figure 1 above shows Micro LED neural electrode probe fabricated by Sekiguchi’s group integrating Allos’ high crystal quality and strain-engineering epiwafer technologies.

Commenting on the challenges, Sekiguchi said: “We need to achieve extreme precision and reliable results. Only industry-grade silicon processing equipment – as we fortunately have at our university – can deliver such processing results. Thus, using Allos’ GaN-on-Si epiwafers which can be processed on silicon lines was the right choice.”

Atsushi Nishikawa, CTO of Allos said: “With our CMOS line ready GaN-on-Si technologies we unlock the benefits those silicon lines bring – including scalability to 200 and 300 mm for low cost and the exceptionally high reliability and yield levels required for all micro LED applications.”

'Development of a neural probe integrated with high-efficiency MicroLEDs for in vivo application' by Hiroki Yasunaga et al; 'Applied Physics (Jpn. J. Appl. Phys. 60, 016503 (2021))