General approach to making perovskite solar cells

TU Dresden researchers identify fundamental processes that occur during the perovskite film formation strongly influence reproducibility

Researchers from the Emerging Electronic Technologies Group of Yana Vaynzof at the Institute for Applied Physics (IAP) and the Center for Advancing Electronics Dresden (cfaed) at TU Dresden have developed a general methodology for the reproducible fabrication of high efficiency perovskite solar cells. Their study has been published in Nature Communications.

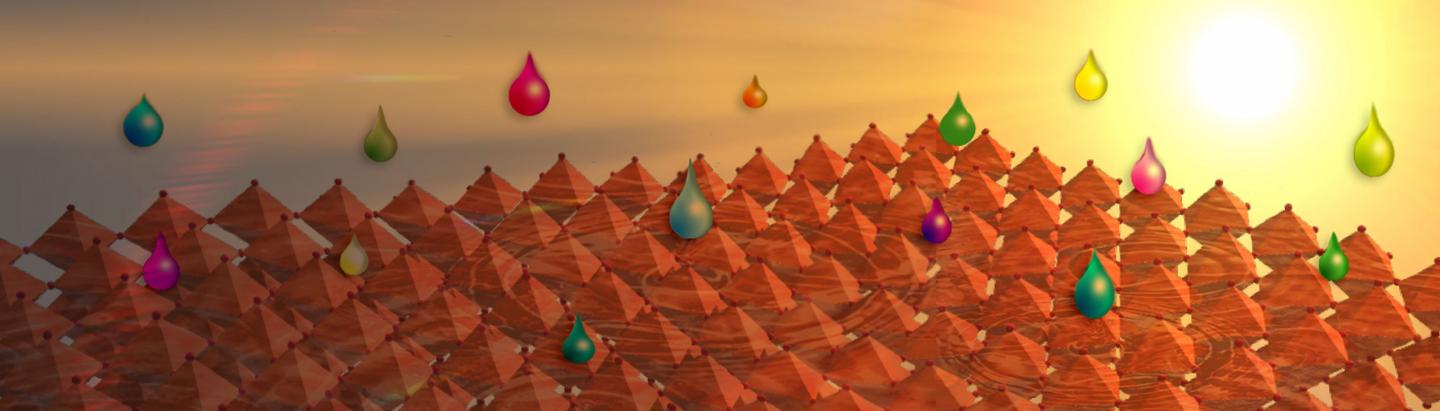

The team has identified that fundamental processes that occur during the perovskite film formation strongly influence the reproducibility of the photovoltaic devices. When depositing the perovskite layer from solution, an antisolvent is dripped onto the perovskite solution to trigger its crystallisation.

"We found that the duration for which the perovskite was exposed to the antisolvent had a dramatic impact on the final device performance, a variable which had, until now, gone unnoticed in the field." says Alexander Taylor, a postdoctoral research associate in the Vaynzof group and the first author on the study. "This is related to the fact that certain antisolvents may at least partly dissolve the precursors of the perovskite layer, thus altering its final composition. Additionally, the miscibility of antisolvents with the perovskite solution solvents influences their efficacy in triggering crystallization."

These results reveal that, as researchers fabricate their PV devices, differences in this antisolvent step could cause the observed irreproducibility in performance. Going further, the authors tested a wide range of potential antisolvents, and showed that by controlling for these phenomena, they could obtain cutting-edge performance from nearly every candidate tested. "By identifying the key antisolvent characteristics that influence the quality of the perovskite active layers, we are also able to predict the optimal processing for new antisolvents, thus eliminating the need for the tedious trial-and-error optimization so common in the field." adds Fabian Paulus, leader of the Transport in Hybrid Materials Group at cfaed and a contributor to the study.

"Another important aspect of our study is the fact that we demonstrate how an optimal application of an antisolvent can significantly widen the processibility window of perovskite photovoltaic devices" notes Prof. Vaynzof, who led the work. "Our results offer the perovskite research community valuable insights necessary for the advancement of this promising technology into a commercial product."

'A general approach to high-efficiency perovskite solar cells by any antisolvent' by Alexander D. Taylor et al; Nature Communications volume 12 (2021)