Riber delivers first MBE 8000 machine to IntelliEPI

Equipment to be used for epi wafer manufacturing for ultra-high performance VCSEL applications

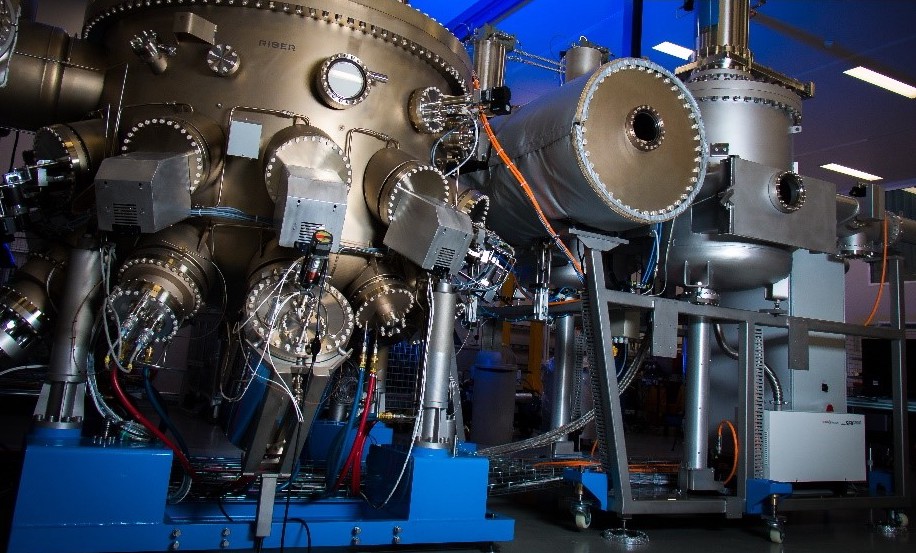

Riber, an MBE equipment company, has delivered the first MBE 8000 system, the world’s largest MBE machine, to IntelliEPI, a longstanding Riber client. This delivery is part of a sales agreement for the equipment to be used for epi wafer manufacturing for ultra-high performance VCSEL applications.

Because VCSEL-based devices emit via the substrate surface, they can be fabricated into devices with high-density arrays of emitters. These components are gradually replacing traditional lasers as the benchmark technology for a growing range of applications - e.g., 3D detection (facial recognition on smartphones) or movement control - across diverse sectors, from consumer electronics to healthcare, automotive and telecoms.

Riber says its MBE technology offers a range of benefits over other technologies. This ability to create very abrupt interfaces combined with very precise dosage control results in improved quality of deposited semiconductor films, enhanced conductivity properties and stronger performance for lasers. In order to address the need for a larger production throughput MBE platform for high performance epi wafer manufacturing with excellent wafer uniformity, Riber has developed the new MBE 8000 production system.

The fully automated MBE 8000 uses an ultra-high vacuum deposition technique. This machine is a multi-wafer reactor with the capacity to grow up to eight 150 mm wafers simultaneously and offers the possibility of transitioning to 200 mm wafers. The machine makes it possible to produce VCSELs and other device structures with precise control down to atomic monolayer precision and with film thickness uniformity well below 1 percent.

For IntelliEPI, the MBE 8000 system will further strengthen its epitaxy capabilities. Alongside its existing fleet of three MBE 49s, eight MBE 6000s, two MBE 7000s, one V90 and one VG100, this new MBE 8000 production platform will enable IntelliEPI to take on the expected increase in demand for its growing VCSEL and other markets, particularly for 6 inch GaAs products with flawless quality to better satisfy its clients.

“This delivery confirms Riber’s leadership on its MBE market and the outstanding features of its MBE 8000 multi-wafer machine, which offers production volumes aligned with the market’s demands. This machine shows that the MBE technology is perfectly optimized and provides additional value-added compared with alternative technologies, especially in terms of operations and output for manufacturing complex semiconductor structures. In addition, the MBE 8000 system presents strong prospects for business development in the future”, confirms Philippe Ley, chairman of Riber’s Executive Board.

"This state-of-the-art MBE 8000 technology platform, with increased throughput and enhanced performance, will enable IntelliEPI to better address the emerging high-performance markets, such as VCSELs for automotive LiDAR, as well as HEMT or HBT for 5G RF applications. One key improvement is the increase in material uniformity across a much larger reactor platform. With future deployment of these MBE 8000 reactors at our expanded manufacturing facilities located in Texas, USA, IntelliEPI will be able to provide even better value products and services to all of its customers" according to Yung-Chung Kao, IntelliEPI president and CEO.