Showa Denko and Infineon sign SiC wafer agreement

Infineon increases supply security for SiC by expanding supplier base

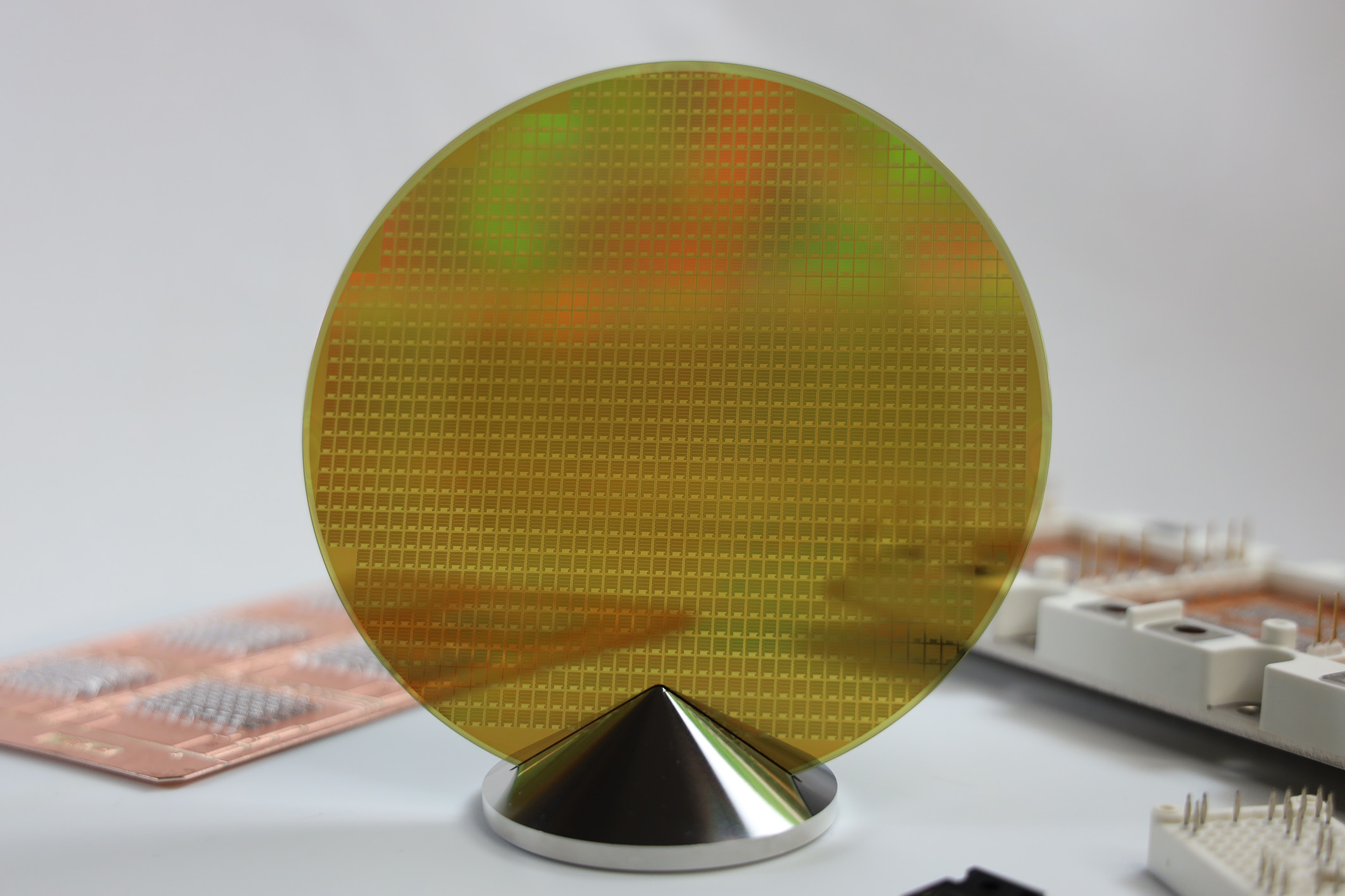

Infineon Technologies has concluded a supply contract with the Japanese wafer manufacturer Showa Denko K.K. for an extensive range of SiC material (SiC) including epitaxy.

The German semiconductor manufacturer has thus secured more base material for the growing demand for SiC-based products.

"Our broad and fast growing portfolio demonstrates Infineon's leading role in supporting and shaping the market for SiC-based semiconductors which is expected to grow 30 to 40 percent annually over the next five years," says Peter Wawer, president of the Industrial Power Control Division at Infineon.

"The expansion of our supplier base with Showa Denko for wafers in this growth market marks an important step in our multisourcing strategy. It will support us to reliably meet the growing demand mid to long term. Furthermore, we plan to collaborate with Showa Denko on the strategic development of the material to improve the quality while cutting costs at the same time."

"We are proud to be able to provide Infineon with Best-in-Class SiC material and our cutting-edge epitaxy technology," says Jiro Ishikawa, Senior Managing Corporate Officer from Showa Denko K.K. "Our aim is to continuously improve our SiC material and develop the next technology. We value Infineon as an excellent partner in this regard."

The contract between Infineon and Showa Denko K.K. has a two-year term with an extension option. Infineon has the industry's largest portfolio of SiC semiconductors for industrial applications.

SDK expects the contract will enable Infineon to apply SDK SiC materials to various power semiconductor products and the two companies to accelerate improvement in quality of products by bringing together the two companies' knowledge.

Due to the homogeneity in properties and low density of surface defects, SDK SiC epi-wafers materials, which were launched into the market in 2009, have been adopted by electronic device manufacturers as parts of various devices including power supply for servers of cloud computing systems, inverters for railcars and solar power generation systems, and converters installed in quick charging stands for EVs.