II-VI Introduces Heated Ion Implantation for 150mm SiC Wafers

Ion implantation foundry process runs temperatures of up to 650 degC to anneal crystal structure dynamically and eliminate defects.

II‐VI, a provider of foundry ion implantation services, has introduced heated ion implantation foundry services for 150 mm SiC wafers.

Acccording to the comany, the process enables highly reliable power electronics by running at temperatures of up to 650degC to anneal the crystal structure dynamically and eliminate defects. The process aldo provides a high level of doping precision, both in terms of depth and concentration.

“To our knowledge, II-VI is the first foundry in the world to provide such advanced ion implantation services commercially for 150 mm SiC wafers and we plan to scale to 200 mm in the future,” said Sohail Khan, executive VP, New Ventures & Wide-Bandgap Electronics Technologies Business Unit.

“II-VI’s new ion implantation process is extremely versatile: It delivers a broad energy range from 10 keV to 1 MeV and can be heated or unheated for a wide range of compound semiconductor wafer materials and devices. This process is compatible with a vast array of materials, including silicon and diamond for special-purpose applications, as well as those that can be integrated into wafer-scale optics platforms.”

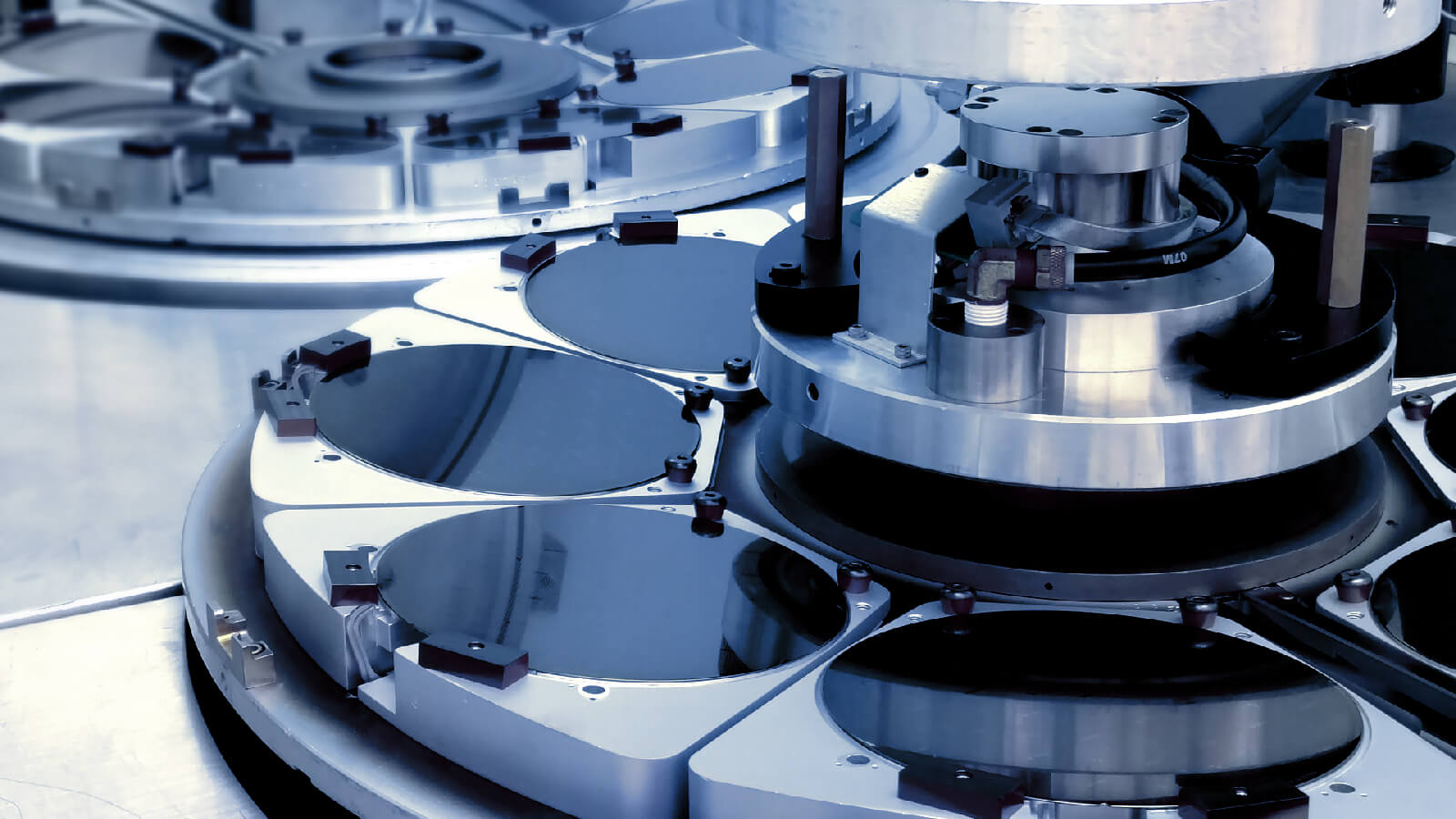

II-VI maintains a large complement of high- and medium-current and high-energy production implanters handling 2-inch to 12-inch substrates. II-VI’s broad range of wafer foundry services includes SiC, GaAs, and InP epitaxial growth. II-VI also provides ion implantation disk refurbishing and reconditioning services to maximise quality, uptime, and utilisation.