Microwave plasma CVD yields high-quality AlN

Ammonia-free growth of crystalline AlN results from high-temperature microwave plasma CVD

Engineers at Beijing University of Technology and Suzhou Institute of Nano-Tech and Nano-Bionics claim to have made substantial progress in growing AlN epilayers with a novel deposition technology.

According to the team, traditional approaches for depositing epilayers, namely MOCVD and MBE, struggle to reach the temperatures of 1400 degC of more that are ideal for the growth of crystalline AlN. Such high temperatures are preferred because they ensure sufficient mobility of aluminium adatoms.

By turning to microwave plasma CVD, the team from China has produced high-quality AlN films at elevated temperatures.

Microwave plasma CVD, which is primarily used for growing diamond, involves heating a substrate by a high-temperature plasma containing growth sources, with heat transferred by conduction and radiation.

One merit of microwave plasma CVD is that, unlike MOCVD and mainstream MBE, it does not use ammonia for the nitrogen source. Ammonia has many drawbacks: it is toxic and corrosive; it is harmful to the environment and the equipment chamber; and it undergoes pre-reactions with precursors, hampering material quality.

The Chinese collaboration is following in the footsteps of research in the 1990s on the growth of AlN by microwave plasma CVD. However, those efforts were restricted to temperatures of around 500degC, a limitation that impacted material quality.

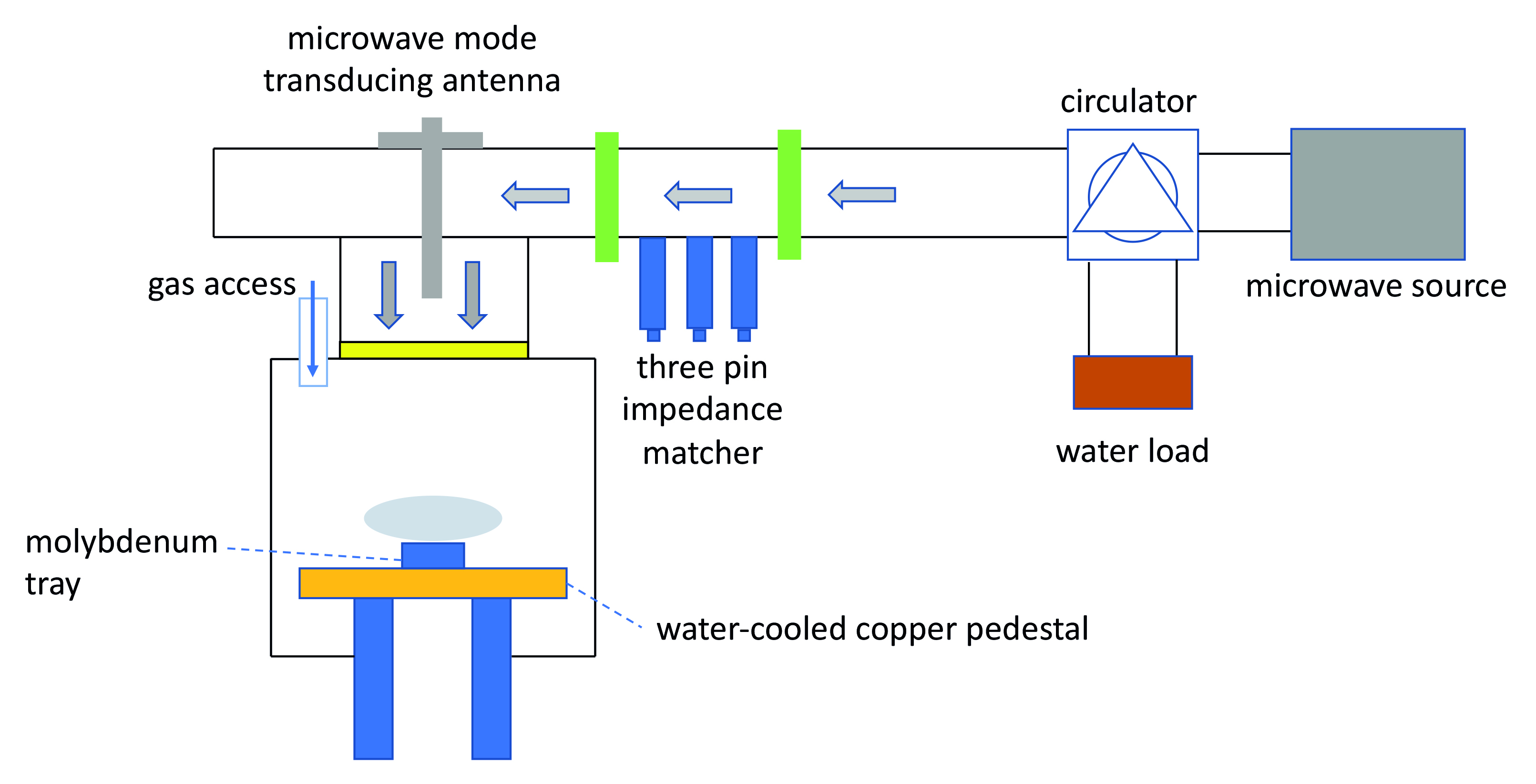

To grow AlN epilayers, the team began by loading 6H-SiC substrates into their home-built microwave plasma CVD system. A 5.6 kW source, emitting at 2.45 GHz, generated microwaves that travelled through the waveguide, entered the reaction chamber and concentrated in the upper regions of the molybdenum tray. These microwaves heated the substrate and activated the plasma of carrier gas and precursors.

Trimethylaluminium and nitrogen provided the group III and V sources, with the latter also acting as a carrier gas. Using flow rates for trimethylaluminium, nitrogen and hydrogen of 38.6 mmol min-1, 330 sccm and 165 sccm, respectively, the engineers deposited AlN films at a range of temperatures from 1200 degC to 1500degC. Even higher growth temperatures could be realised by turning to a higher chamber pressure and a more powerful source of microwaves.

An hour’s growth at temperatures of 1300degC, 1350degC, 1400 degC and 1450 degC produced AlN films with thicknesses of 540 nm, 520 nm, 510 nm and 490 nm, respectively. No growth occurred at 1200degC, because at this temperature the activity of nitrogen gas is insufficient to decompose and react with the group III source; and at 1500degC, excessive etching by hydrogen gas prevented deposition of an AlN film.

According to high-resolution X-ray diffraction spectra, higher growth temperatures led to better material quality. For an AlN epilayer grown at 1450degC, values for the full-width at half-maximum in the (0002) and (1012) directions were 142 arcsec and 350 arcsec, respectively.

The team attributed the superior crystal quality at higher growth temperatures to increased adatom mobility and greater etching by the hydrogen plasma. The etching is more prevalent in poorer quality domains, which are more amorphous and have a greater proportion of polycrystalline content.

Insights provided by X-ray photoelectron spectroscopy enabled an assessment of the stoichiometry of the epilayers. The ratio of aluminium-to-nitrogen is 1:0.95 in the AlN film grown at 1300degC, and equal in that formed at 1450degC. This finding supports the conclusion from X-ray diffraction measurements that higher growth temperatures ensure better material quality.

Higher growth temperatures also produce smoother films, according to atomic force microscopy. Epilayers grown at 1300degC have a root-mean-square surface roughness of 3.6 nm, compared with 0.6 nm and 0.8 nm for AlN layers grown at 1400degC and 1450degC, respectively.

The picture above shows using nitrogen and trimethylaluminum sources, microwave plasma CVD produces high-quality AlN films.

Reference

Y. Zhang et al. Appl. Phys. Express 14 055503 (2021)