Pre-Well Structure Enhances Yellow LED Performance

WHU team improves performance by introducing InGaN/GaN pre-well structure beneath multiple quantum wells

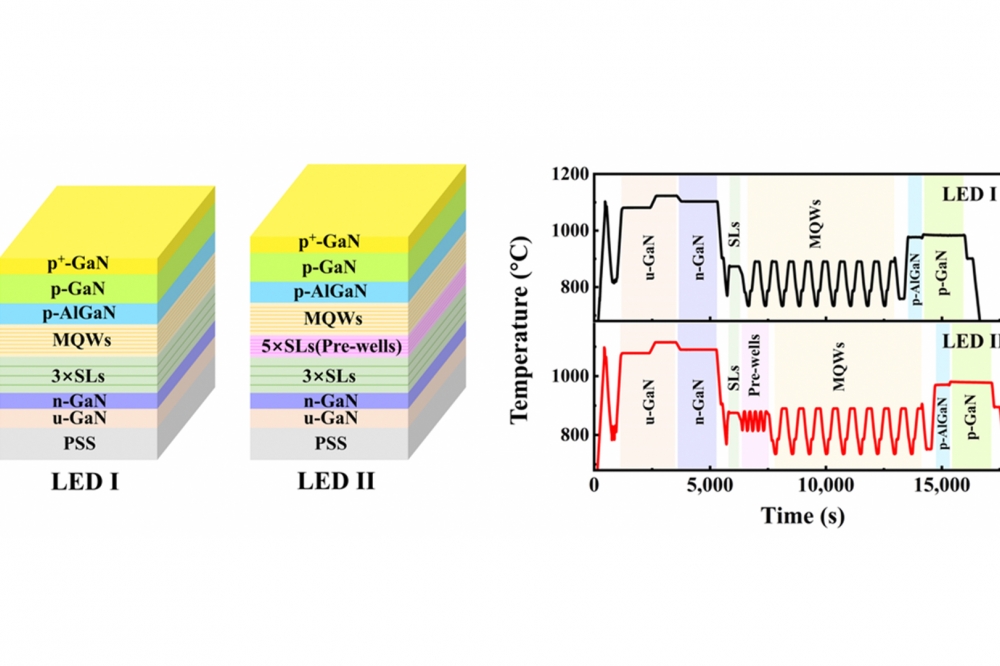

Researchers from Wuhan University in China have reported the adoption of InGaN/GaN pre-wells to improve the efficiency of yellow (~575 nm) light-emitting diodes (LEDs).

“We reveal that benefiting from the pre-well structure, in-plane compressive stress is reduced, which effectively suppresses the quantum confined stark effect (QCSE). Furthermore, the increased quantum efficiency is also related to deeper localised states with reduced non-radiative centres forming in multiple quantum wells (MQWs) grown on pre-wells.” said Shengjun Zhou, a professor at Wuhan University who directed the research.

III-nitride emitters have attracted a lot of attention due to their advantages of energy savings, high brightness, and long lifetime. With the wide and tunable band gap, InGaN-based LEDs find widespread applications in the solid-state lighting and full-colour display.

In recent years, the increasing need of flexible lighting devices motivates the manufacturing techniques development for deformable micro-LEDs and the progress of flexible micro-LEDs applications in the optogenetic biomedical field. Though blue LEDs achieving a high external quantum efficiency, the emission efficiency is still limited in the long-wavelength region, which is commonly known as “green-yellow gap” phenomenon.

The researchers introduce additional InGaN/GaN pre-wells in LED structure and investigate the influence on optoelectronic properties of yellow (~575 nm) LEDs. LED with pre-wells exhibits better optoelectronic properties, especially an increase in light output power of 13 mW, which is 2.2 times higher than that for LED without pre-wells at 20 mA. Experiment results reveal that this structure plays a vital role for stress relaxation. The performance enhancement is attributed to alleviated detrimental influence of QCSE and strengthened carrier localisation in MQWs grown on pre-wells.

'Enhanced Optoelectronic Performance of Yellow Light-Emitting Diodes Grown on InGaN/GaN Pre-Well Structure' by Xiaoyu Zhao et al; Nanomaterials 2021, 11(12), 3231.