Luminar to acquire laser chip firm Freedom Photonics

Luminar now vertically integrated across core lidar components

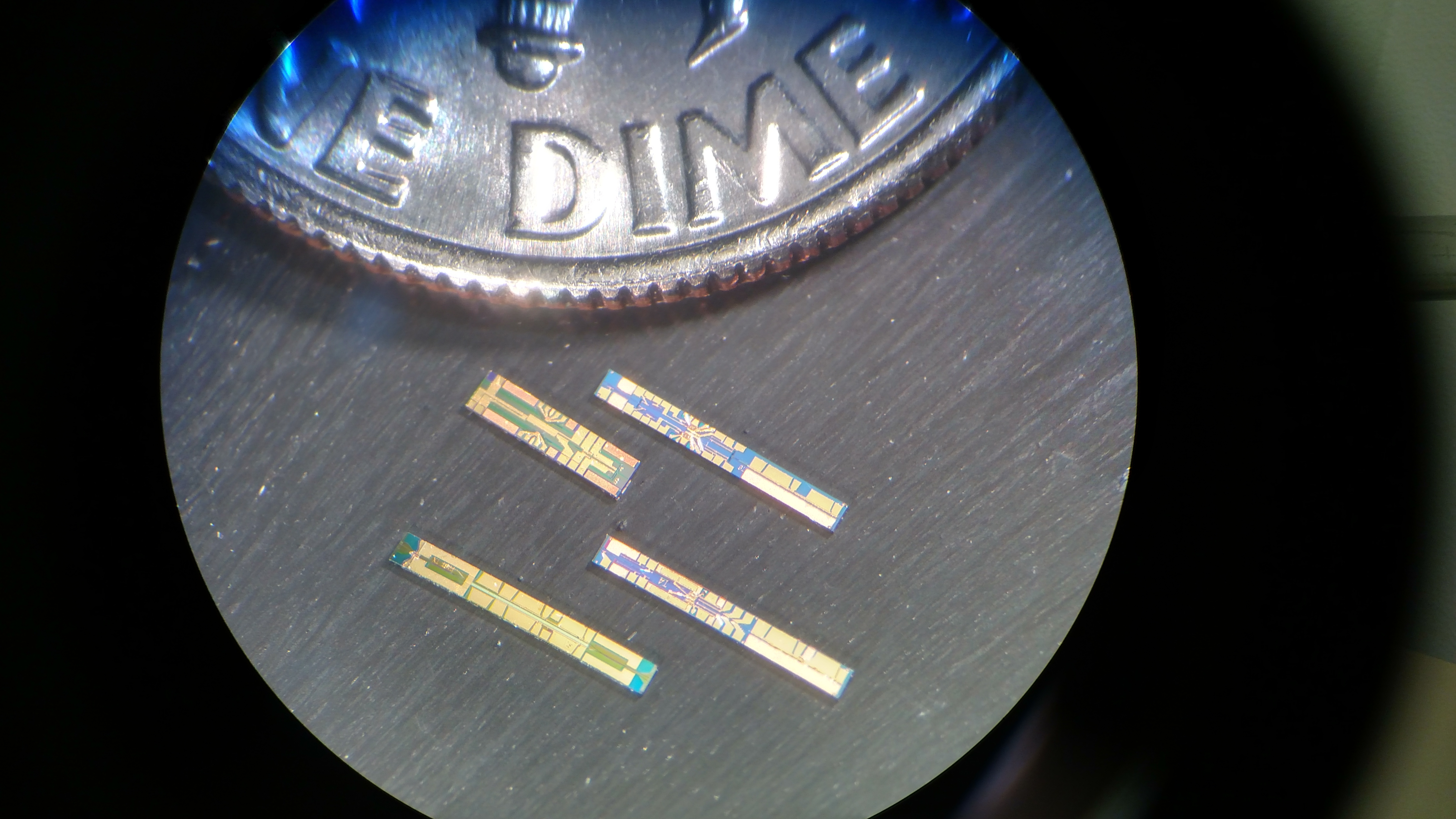

Luminar, a US-based automotive technology company, is acquiring laser manufacturer Freedom Photonics. This transaction follows a multi-year collaboration and brings fundamental next-generation chip-scale laser technology, IP, and production expertise in-house for Luminar lidar systems.

Luminar is vertically integrating across core lidar components that will enable low costs, supply chain security and improved performance. This transaction follows the acquisition of subsidiaries Black Forest Engineering for custom signal processing chips in 2017 and Optogration in 2021 for receiver chips.

“Component-level innovation and integration is critical to our performance, cost and continued automotive technology leadership. Bringing Freedom Photonics into Luminar enables a new level of economies of scale, deepens our competitive moat and strengthens our future technology roadmap,” said Jason Eichenholz, co-founder and CTO at Luminar.

“We’ve worked closely with the Freedom team for the past several years. They have proven to be the best in the world for breakthrough semiconductor laser chip technology, where both power and beam quality are needed simultaneously for true high resolution at long range.”

The Freedom Photonics executive team will continue to lead and expand the business upon close of the transaction, which is expected in the second quarter.

“Joining Luminar is the perfect opportunity for Freedom Photonics, providing us an accelerated path to at-scale commercialisation of our world-class diode laser technologies,” said Milan Mashanovitch, co-founder and CEO at Freedom Photonics. “In addition to helping extend Luminar’s automotive industry leadership, we will continue to serve and grow our broad customer base across other key markets.”