ZSW to fast track perovskite tandem solar cells

Two new high-performance coating plants now up-and-running to drive development towards market maturity

The Centre for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW) now aims to fast-track tandem perovoskite solar technology’s time to market. To this end, its researchers have put two new high-performance coating plants into operation.

These systems produce tandem solar cells consisting of a perovskite solar cell that can be combined with other types of solar cells. The various layers are deposited under ultra-clean conditions. Companies in the solar sec-tor can take advantage of these capabilities to optimise their developments in the area of tandem solar cells.

Propelled by advances in research and manufacturing, solar modules’ performance is on the rise. However, further increases in individual solar cells’ efficiency are becoming a progressively challenging and expensive proposition. What’s more, the efficiency of silicon cells that currently dominate the market is gradually approaching the practical limit of around 27 percent.

Tandem solar cells offer a way out of this dilemma. “They consist of different solar cells layered on top of one another,” says Jan-Philipp Becker, the new head of the ZSW's Photovoltaics: Materials Research department. “Together, the layers make better use of the width of the solar spectrum than each single solar cell.”

The top solar cell converts light in the visible region of the solar spectrum into electricity; the bottom cell converts light in the near-infrared spectrum. This combination is the reason why tandem solar cells have a higher potential efficiency, which is expected to rise well over the 30 percent mark in the years ahead. Several variants of tandem cells are now available.

Highly efficient, light and flexible

A particularly interesting variant of tandem solar cells uses layers of perovskite as the light-absorbing material. For the second absorbing layer, ZSW researchers have opted to use cells made of CIGS, silicon, or another perovskite with a modified spectral sensitivity range. Combinations of different cell types – that is, perovskite and CIGS, perovskite and silicon, or perovskite and perovskite – hold great promise as a means of significantly boosting efficiency.

Tandem solar cells that pair perovskite with perovskite or perovskite with CIGS have benefits beyond high efficiency. As a thin-film technology, they can also be deposited on plastic or steel films to make light, flexible modules that are perfect for mounting overhead orchards, in vehicle roofs and integrated into building façades or roofs.

Up and running research plants

The ZSW now has two plants up and running to drive this development towards market maturity. One makes perovskite thin-film solar cells and the other CIGS thin-film solar cells. Tandem solar cells with silicon semiconductors can be produced on various silicon cells sourced from external partners.

“Excellent conditions are now in place in the institute to develop tandem solar cells, particularly in terms of the process tech-nology for manufacturing solar cells in a vacuum under ultra-clean lab conditions. We want to use these assets to explore the technology’s physical boundaries,” says Becker. An extensive set of material analy-sis tools helps with that. The in-house Solab test laboratory and field-testing facilities are able to rigorously analyze and assess the manufac-tured solar cells and modules for long-term stability. The new plants will serve to develop innovative processes for the solar industry, which will then be able to bring to market more efficient and cost-effective solar modules.

The ZSW draws on more than 30 years’ experience with CIGS technology. The institute’s experts developed, optimised and ramped up thin-film photovoltaics systems for mass manufacturing. Now they want to continue that achievement with tandem solar cells where they have already achieved very good efficiency values.

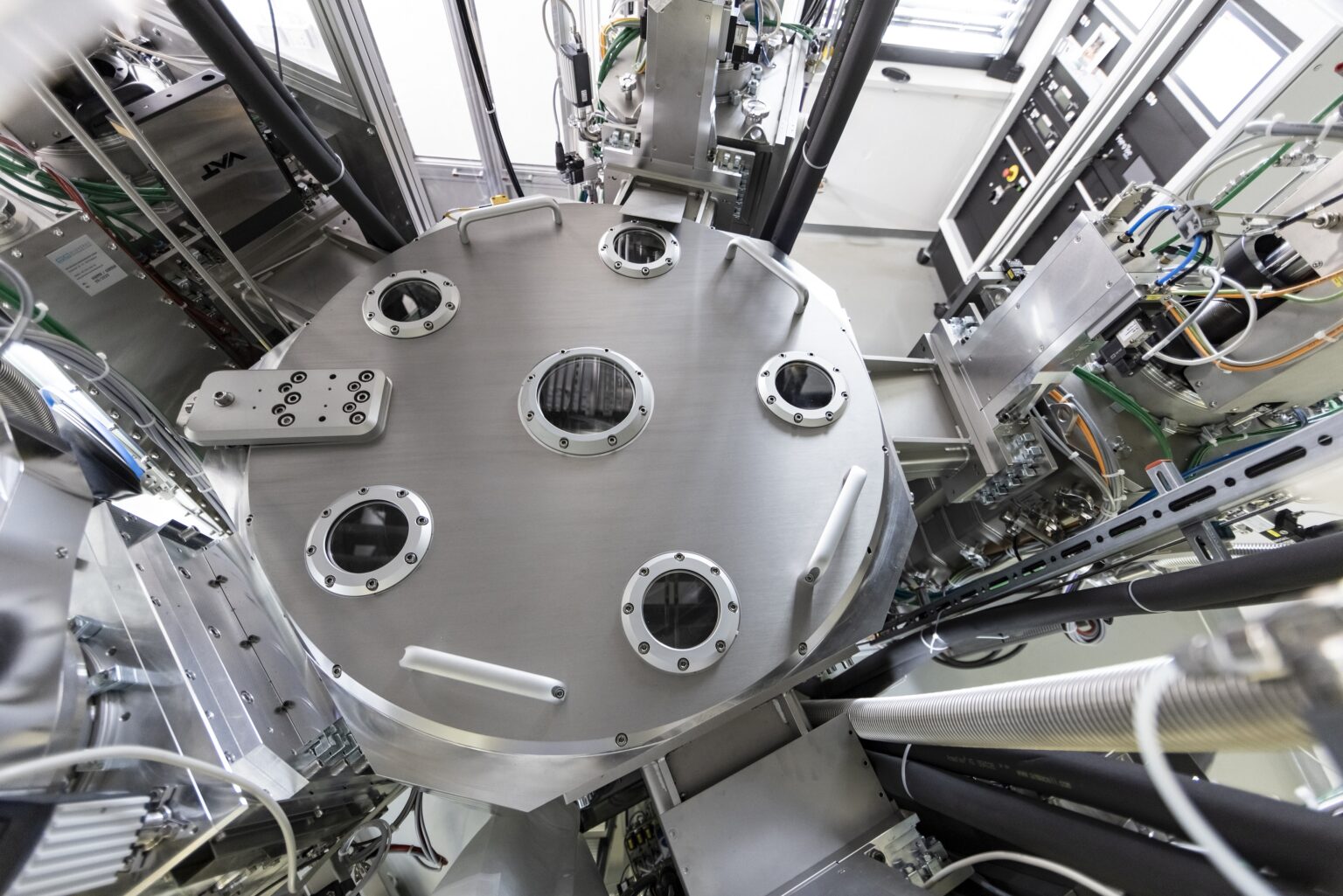

Arrayed around a central robot, the perovskite cluster’s four coating chambers can produce a wide variety of solar cells with sputtered transparent layers and with evaporated metallic or organic layers. A vacuum chamber provides optimised means of vacuum-coating perovskites. The system will be able to create very homogenous and highly reproducible multi-component perovskite layers. Even at this early stage, the ZSW has already made great strides in optimising the cell structure with vapor-deposited organic electron conductor layers.

The German Federal Ministry of Economic Affairs and Climate Action (BMWK) funded the two plants as part of the CAPITANO and CIGS-Cluster projects.