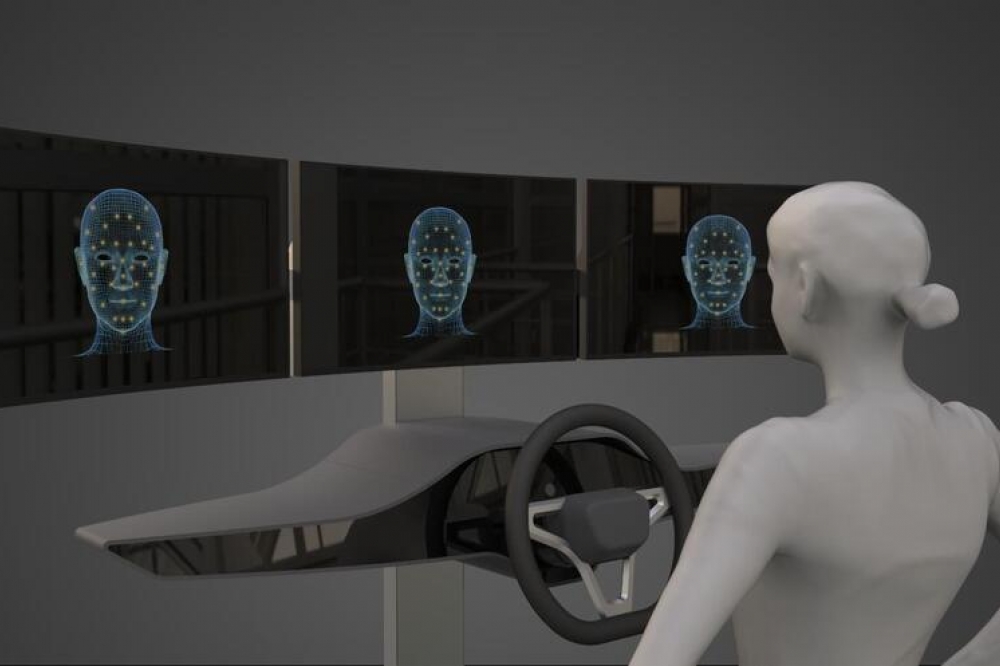

Ams Osram reveals 3D sensing proof-of-concept

Supports advanced driver monitoring features

Ams Osram has unveiled the ICARUS proof-of-concept which shows how to upgrade designs for Driver Monitoring Systems (DMS) to support valuable new features such as an augmented reality head-up display (AR-HuD), secure driver authentication, and advanced drowsiness detection.

Ams Osram exhibited the ICARUS system at the Automotive Engineering Exposition (Yokohama, Japan, 25-27 May 2022).

ICARUS is mounted in the instrument cluster or A-pillar. The Ams Osram 3D sensing system provides high-resolution depth maps (<±0.5 percent depth accuracy at a range of 45-70cm) using a structured light method. It uses an Ams Osram depth-extraction algorithm which offers scope for even higher performance in future for customers which support custom product development. The system is implemented with automotive VCSEL near infrared (NIR) flood and dot pattern projectors from Ams Osram.

Customers can deploy their DMS software in tandem with the accurate depth map of the driver’s face to determine the 3D position of the driver’s eyes and head pose. High-value driver monitoring functions such as AR-HuD and driver authentication can be based on this 3D position information.

The ICARUS system’s accurate measurement of the position of the driver’s head in 3D also supports the implementation of software to detect micro-sleeps and other advanced signs of drowsiness which pose a risk to road safety.

ICARUS shows automotive OEMs that there is a straightforward, low-cost upgrade path from DMS designs which use 2D NIR sensing to a full-featured, high-value 3D sensing system. The upgrade requires only the addition of an NIR dot pattern projector and supporting depth extraction software.

“Structured light sensing technology is proven in the consumer market, where it is used for instance for secure face authentication in mobile phones,” said Firat Sarialtun, Global Segment Manager for In-Cabin Sensing at Ams Osram.

“Previously in the automotive world, however, 3D sensing has only been implemented with dedicated indirect time-of-flight (iToF) cameras. The ICARUS system shows that the automotive industry can take advantage of the experience of 3D sensing which Ams Osram has gained in the consumer world, and apply it to upgrade existing 2D NIR-based DMS systems simply and at low cost, with the addition of just a single laser component.”

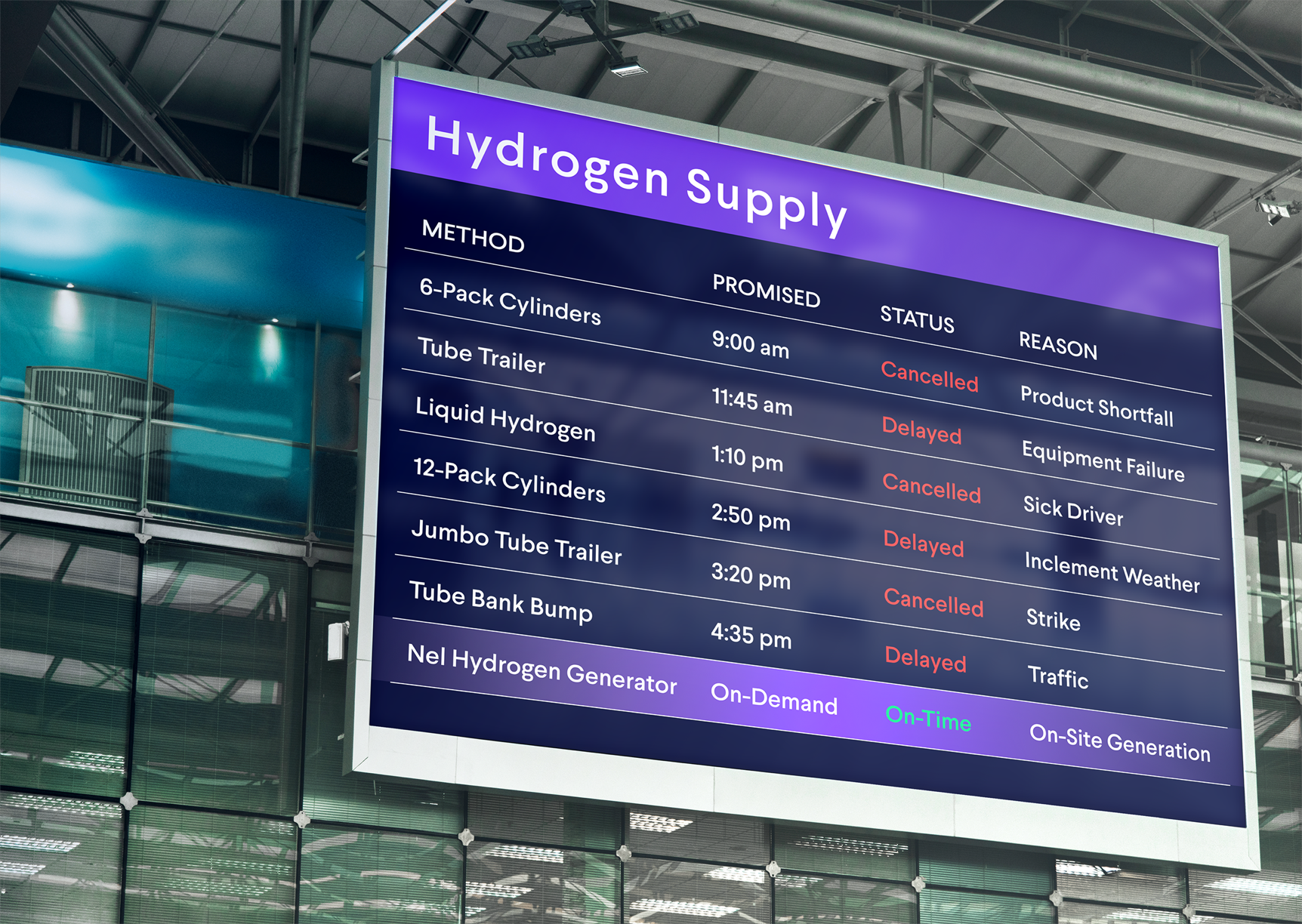

Secure Your Hydrogen Supply

A study supply of high-purity hydrogen is critical to semiconductor fabrication. Supply chain interruptions are challenging manufacturers, leading to production slowdowns and stoppages. On-site hydrogen generation offers a scalable alternative for new and existing fabs, freeing the operator from dependence on delivered gas.Plant managers understand the critical role that hydrogen plays in semiconductor fabrication. That important job includes crystal growth, carrier gas, wafer annealing, and in the emerging Extreme UV Lithography (EUV) that will enable new generations of devices. As the vast need for semiconductors grows across all sectors of world economies, so does the need for high-purity hydrogen.

Take control with Nel on-site hydrogen generation.

Read more

.jpeg)