WIN Semi and University of Southern California partner on GaAs and GaN tech

MOSIS Service of Information Sciences Institute to accelerate the development of MMICs with WIN partnership

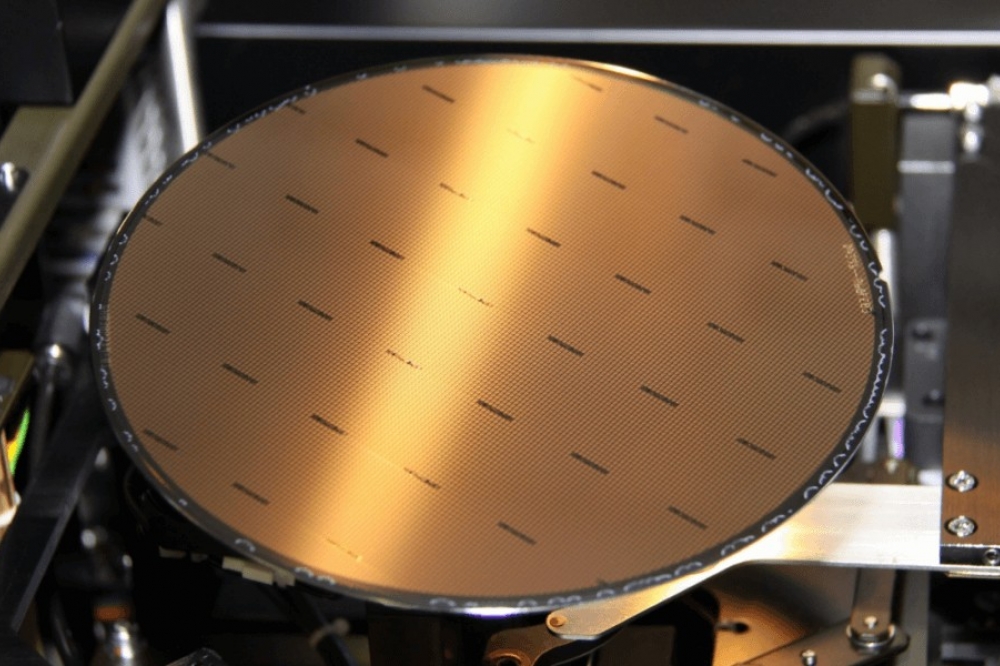

University of Southern California's MOSIS Service of Information Sciences Institute will use WIN Semiconductors’ GaAs and GaN process technologies to accelerate the development of Monolithic Microwave Integrated Circuits (MMICs).

The collaboration combines the MOSIS semiconductor design support and manufacturing expertise, including Multi-Project Wafer (MPW) runs, and WIN Semiconductors’ technologies for high-speed devices using III-V compound semiconductors including GaAs and GaN, and prototype packaging technologies.

With this collaboration universities, research organisations, and industry organisations will have access to an extensive portfolio of heterojunction bipolar transistor (HBT), pHEMT and RF GaN HEMT technology platforms to develop new high performance MMIC designs including amplifier designs and integrated front ends operating from 100 MHz to 175 GHz.

The collaboration lays the foundation for innovative, reliable, and efficient design and prototyping flows through the MPW projects with The MOSIS Service and WIN Semiconductors.

“This is a new and important capability for The MOSIS Service to provide access and support to non-silicon wafer fabrication processes with the microelectronics community.” said Craig Knoblock, executive director of Information Sciences Institute.

“For the first time, the US Government, R&D laboratories, companies, and academia will have access to WIN Semiconductors’ portfolio of III-V compound semiconductor processes with MOSIS’ legacy design and manufacturing service capabilities. We are confident that this collaboration will significantly advance microelectronics R&D and accelerate the development of advanced GaAs and GaN MMICs.”

“We are excited to launch this initiative with WIN Semiconductors” said Lifu Chang, director of The MOSIS Service. “WIN Semiconductors is the world leader in the pure-play compound semiconductor foundry space and offers a comprehensive portfolio of III-V technologies. These III-V foundry technologies require a higher level of design-technology interplay compared to silicon technologies. Our MOSIS experience provides a platform for tightly coupled and efficient design and manufacturing flows, to support universities and design companies interested in high-performance front-end applications.”

Knoblock echoed this statement, “There are serious concerns with the access to wide varieties of semiconductor processes and design support for universities and corporations in the US, in the context of worldwide competition and wafer supply constraints. The MOSIS Service is positioned to contribute to the resolution. The addition of GaAs and GaN technologies is necessary, and we will push hard in this direction.”

WIN Semiconductors’ SVP of Technology and Strategic Business Development, David Danzilio, said: “The collaboration between WIN Semiconductors and The MOSIS Service creates a new platform for many new users to access WIN’s market leading compound semiconductor technologies.” Danzilio pointed out, “We are building a robust project framework with MOSIS’ Team. I expect to attract and enable many customers that have been interested but need the level of technical support that MOSIS can provide. WIN is the largest pure-play compound semiconductor foundry, and we welcome the new customer engagements provided by The MOSIS Service”.