UV-A LED has 75 percent higher power density

Luminus releases innovative surface mount device based on Gen5 die architecture

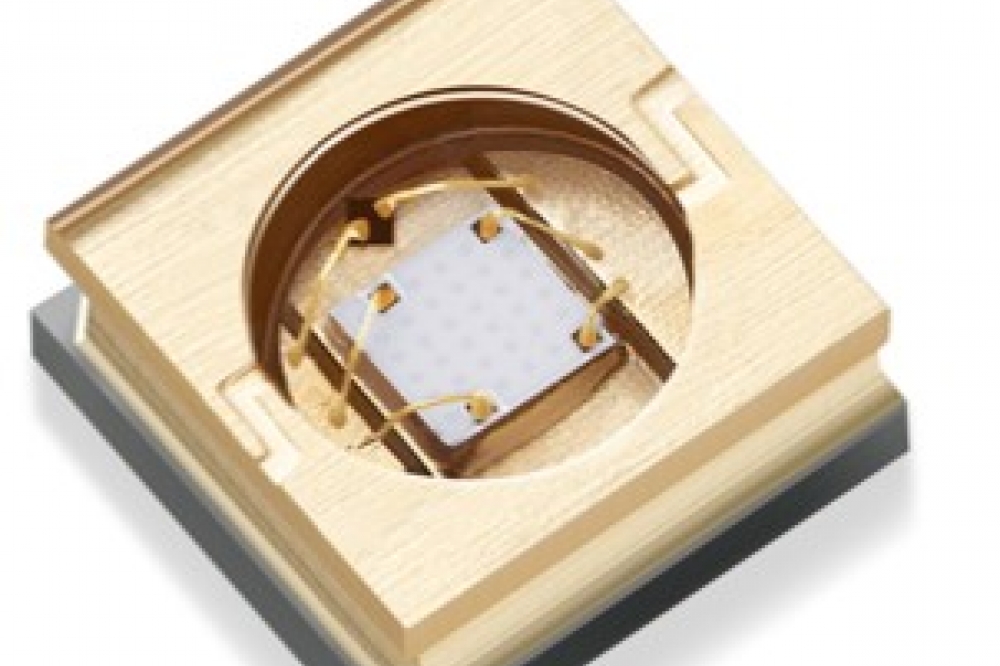

Luminus Devices has announced the release of the SBT-10X-UV LED series, an innovative surface mount device (SMD) that uses Luminus’ latest Gen5 die architecture.

Delivering up to 75 percent higher output than Luminus’ Gen4 die, the Gen5 technology achieves a high flux of up to 5W from a single 1 mm2 class chip. As such, it improves end-system performance for the most demanding curing applications including 3D printing, curing and maskless lithography, where maximum flux density directly translates to faster curing and higher productivity.

The Gen5 technology integrates know-how in very high intensity chip structures that Luminus has developed and improved for over 15 years. This technology achieves excellent reliability at drive conditions often 2x what the competition supports. It is available in 365nm, 385nm, 395nm, 405nm and 415nm wavelengths and comes in a compact 3.5 mm x 3.5 mm surface mount cavity package with a flat borosilicate cover helping maximise optical coupling efficiency into the end system.

David Nowak, senior marketing manager, comments, “The SBT-10X brings our Gen5 technology in its most compact form factor which will help accelerate adoption in a wide range of industrial systems that are starved for UV-A curing performance. We are especially excited to enable more compact, affordable high-resolution 3D printers that will help accelerate the adoption of the technology in prosumer segments thanks to affordable and compact printers that do not sacrifice quality.”

.jpeg)