Getting GaN VCSELs to market

Mirrors formed by alternating conventional layers of GaN with

porous equivalents are set to drive the commercialisation of blue and

green VCSELs.

BY RICHARD STEVENSON, EDITOR, CS MAGAZINE

Over the last few years the GaN VCSEL has come on in leaps and bounds, enjoying substantial gains in lifetime, efficiency and output power. Thanks to all this great progress, blue and green VCSELs are now standing on the brink of commercialisation.

Taking this next step is far from easy, but the chances are now better than ever, thanks to a significant breakthrough from a little-known a start-up that’s located far away from the centre of the action. While much of the early running has come from big names in Japan, such as Nichia, Sony and Stanley Electric, the driver of GaN VCSEL commercialisation is Ganvix of Wilmington, DE.

What distinguishes this trailblazer from its peers is the approach it takes to form the bottom mirror of the VCSEL. Rather than making a distributed Bragg reflector (DBR) from interlacing layers of GaN and a ternary nitride – a pairing that is slow to grow, and, due to a lack of lattice-matching, introduces light-quenching defects into the active region – Ganvix combines conventional layers of GaN with porous variants, produced by electrochemical etching.

Company CEO John Fijol told Compound Semiconductor that the start-up is planning to sample VCSELs to its customers in early 2023, targeting output powers of 5 mW or more.

“We see a lot of nascent opportunities in markets like consumer electronics, communications, industrial devices, sensors,” says Fijol. “There's a lot of overlap with markets where the gallium arsenide VCSELs have seen success, but with applications in those markets that require blue or green wavelengths.”

Bringing together all three colours of VCSEL to form a light-engine for pico-projectors and other projection systems is another opportunity for these lasers, which are valued for their small size and colour purity.

Like their infrared cousins, blue and green VCSELs could also server in communication – but rather than transmitting through a glass fibre, light would be directed through a polymer fibre or free space.

For the next year or so, Ganvix intends to be very selective about the customers it works with, directing its focus on an initial product entry. “We're not in stealth mode by any means, but we're also not at the point where we want to do broad marketing activities and fish for customers,” says Fijol.

The output powers of today’s Ganvix VCSELs are not as high as the hero devices that have come out of Japan, such as the 22.2 mW laser from Stanley Electric. However, rather than seeing this shortfall as a gap to bridge, Fijol takes encouragement from these higher figures, showing what’s possible.

Right now, breaking power and efficiency records is not at the top of Ganvix’s agenda. “Our focus for the last year has been more on developing manufacturing,” remarks Fijol, revealing that the emphasis has been on improving production through the development of robust designs, advancing cost-effective processing and introducing superior metrology techniques.

Thanks to progress on all these fronts, Ganvix has what Fijol describes as “very solid processes for the building blocks”. There is proficiency for producing the DBR, the active region, and the optical cavity.

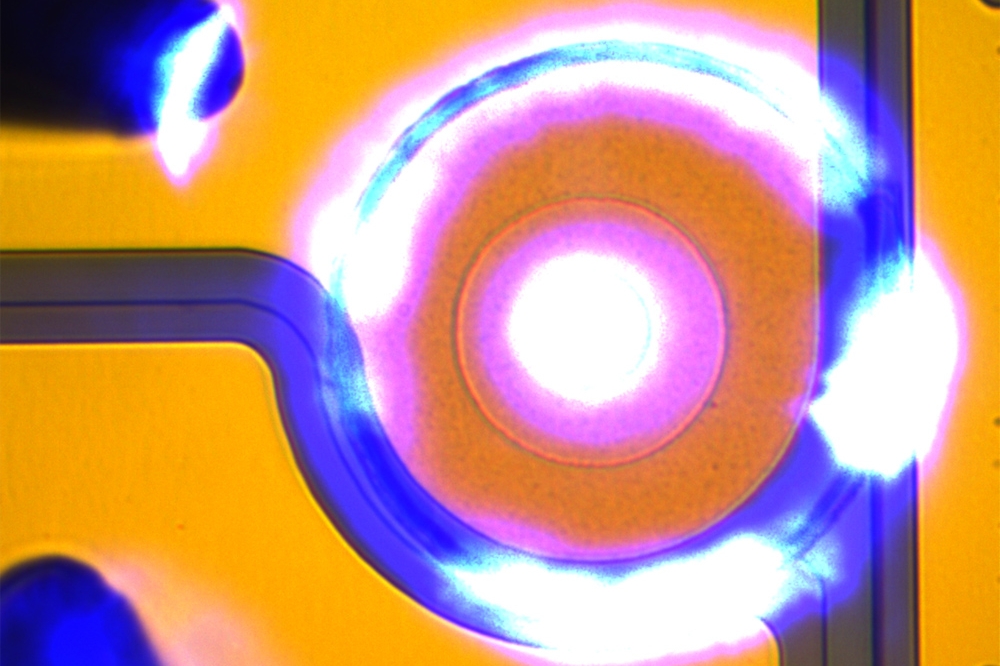

On-wafer measurements can be used to assess the quality of the VCSEL

To form the DBRs, engineers grow a GaN stack that features layers with different doping concentrations. A subsequent electrochemical etch that takes place after device fabrication introduces the porous structure that creates the mirrors.

“The density and size of the nanopores can be very precisely controlled, by adjusting current and voltage settings during the process,” reveals Fijol. “This allows us not only to create the porosity, but tailor the optical properties of those layers.”

Ganvix combines a partially porous GaN mirror, which typically needs fewer layer pairs than a traditional GaN-based mirror, with a dielectric top mirror. “We could create a very high quality top DBR [with our porous technology], but from a process standpoint it's easier for us to use the dielectric DBR.”

For those considering whether to adopt a Ganvix VCSEL, one possible concern might be the threat of contamination entering the porous structure. “But that doesn't happen because of the passivation,” explains Fijol, who points out that these structures are inherently stable. He says that another strength of the Ganvix design is that it eliminates the possibility of lower electrical and thermal connectivity near the active region.

Working with ITRI

Ganvix has teamed up with the Industrial Technology Research Institute (ITRI) in Taiwan to accelerate technology development and speed time to market. Fijol explains that the are many reasons why Ganvix has chosen to work with ITRI. Part of the motivation is the large, active electro-optics community in Taiwan; and another factor is the long-established relationship between ITRI and key personal at Ganvix. For example, independent board director of Ganvix, Jacob Tarn, previously launched Epistar through ITRI; and Ganvix founder and inventor Jung Han sits on ITRI’s technical advisory board.

(a), (b), (c) and (d) The architecture of the Ganvix VCSEL includes a nanoporous bottom DBR and a dielectric top DBR. (e) The measured reflectivity profile of the DBR is in excellent agreement with the results of simulation

To manufacture its VCSELs, Ganvix needs a line that has tools to produce the porous DBR and assess its quality. “But other than that, we've worked very hard to develop a process that is compatible with standard gallium nitride processing,” remarks Fisol.

This approach should help the US start-up expand from establishing an initial product to building a broad portfolio that will pave the way for a catalogue-type business.

Another possible goal for Ganvix is to bring light engines to market that are based on red, green and blue VCSELs. “We're working on building the partnerships with existing manufacturers of red devices that will enable us to provide a complete solution for customers.”

With a foundation for volume production in place, and a compelling roadmap for the VCSEL, there’s good reason to believe that commercial products based on this class of laser will soon be spanning the visible domain.