Reverse polarization invigorates the green LED

Switching to a p-down architecture produces a near-theoretical operating voltage for the green LED.

BY

SHEIKH IFATUR RAHMAN, ZANE JAMAL EDDINE, AGNES XAVIER AND SIDDHARTH

RAJAN FROM OHIO STATE UNIVERSITY AND ROB ARMITAGE FROM LUMILEDS

The GaN-based LED has come an awfully long way since its invention in 1989. Initially emitting blue light, then white once combined with a phosphor, this device enjoyed its first killer application from backlighting the keypads and screens of mobile phones. Further success followed with the backlighting of larger screens, found on TVs, laptops and tablets; and today sales are even more substantial, thanks to the deployment of this device in general illumination, transport and horticulture. And that may not be the end of the line, as this device is now showing promise in microLED displays.

Yet despite all this great and varied success, there are weaknesses that need to be addressed. While the efficiency of emitters in the violet and blue is now exceptional, the value for this key figure of merit plummets at longer wavelengths. The issue is that when engineers stretch the emission wavelength to 500 nm or more by increasing the indium mole-fraction of the InGaN quantum wells, they come up against several challenges, all contributing to degradation in device performance and a decline in wall-plug efficiency.

Figure 1. (a), (b) Equilibrium band diagram of p-up and p-down

configuration showing a low hole-injection barrier for a p-down design

compared with a p-up variant; and a higher in-built electron barrier for

p-down, improving confinement of electrons in the quantum well compared

to p-up. (c) Simulated current density versus voltage (J-V) curve for

the p-up and p-down LED structures.

How does polarization impact LEDs?

InN, GaN, and AlN are all examples of group III-nitride wurtzite materials that are pyroelectric and display spontaneous and piezoelectric polarization. Due to these characteristics, heterostructures formed from different alloy compositions of III-nitrides have inherently large spontaneous and piezoelectric polarization sheet dipoles at their interfaces. When these materials form thin sandwich-like layers, such as quantum wells, this results in large electric fields within the wells, and depletion regions outside the wells.

To emit at wavelengths beyond 500 nm, the cusp of the green spectral domain, the average indium composition in the quantum well must exceed 20 percent. Adding this much indium or more pays the penalty of an increased electric field strength within the quantum wells, influencing the distribution and lifetime of free carriers in these light-emitting layers. Higher fields can diminish the performance of InGaN/GaN-based optoelectronic devices and increase their operating voltage.

In conventional LEDs, formed by growing the n-type region first, followed by the active region and then the p-type region – such structures may be known as simply p-up LEDs – the polarization sheet charges oppose the depletion region field across the p-n junction. This leads to higher electrostatic barriers that impede the injection of electrons and holes, and ultimately a higher forward-voltage drop (see Figure 1 (a)).

One interesting alternative architecture is formed by reversing the relative direction of the p-n junction. This is realized by placing the p-layer below the active region, rather than above it. With this geometry, the polarization field no longer opposes the depletion barrier field. Instead, these aligned fields are beneficial, helping to lower injection barriers for electrons and holes into the active region (see Figure 1 (b)).

For the indium-rich wells needed to realize longer-wavelength emission, such as the green, this carrier-assisting effect is particularly strong. According to simulations, there is a significant reduction in the injection barrier, leading to a tremendous reduction in the forward turn-on voltage for p-down LEDs compared with their traditional cousins (see Figure 1 (c)).

Why do we need tunnel junctions?

There are two options for reversing the relative orientations of the p-n junction and polarization. One is to maintain the conventional p-up architecture, but to switch substrate and grow along the –c or N-polar direction of the wurtzite crystal structure. The alternative is to grow a p-n junction with the p-type region below the active region, along the +c or Ga-polar direction.

Our collaboration between Ohio State University and Lumileds has been evaluating these approaches for many years. In 2012 we broke new ground, providing the first demonstration of the N-polar green LED. This work illustrated the benefits of reversed polarization, such as a lower turn-on voltage and a reduced overflow. But we found that the N-polar orientation is not a panacea – it can introduce challenges associated with a higher point defect incorporation, which diminishes the internal quantum efficiency.

It is preferable to produce LEDs with the same sense of polarization as the p-n diode, but with growth along the Ga-polar direction. For this particular design, the concern is that since the p-layer is at the bottom, the spreading resistance of the p-layer could lead to current crowding.

A team from Cornell has tackled this issue by inserting a tunnel junction below the p-layer. However, operating voltages for these p-down green LEDs were significantly higher than those of conventional variants.

We have had more success with this approach. This has led us to show, for the first time, that highly efficient tunnel junctions can be integrated within p-down LEDs to yield green-emitting sources with an extremely low operating voltage.

Figure 2. (a) Equilibrium band diagram of the p-down LED using a bottom tunnel junction. (b) The finished/processed device.

How did we demonstrate the result?

Fabrication of our novel LEDs began with the growth of an epitaxial structure by plasma-assisted MBE (see Figure 2). We prefer this growth technology to MOCVD for our novel LEDs: it enables the sharp doping profile and the high magnesium and silicon doping densities that are essential for good homojunction tunnel junctions.

Our on-wafer measurements clearly show the benefit of reversed polarization. When driven at current densities of 20 A cm-2 and 100 A cm-2, the forward voltages for our LEDs are just 2.42 V and 2.75 V, respectively (see Figure 3 for a plot of the dependence of current density on voltage for these devices).

Figure 3. (a) Electrical characteristics of p-down tunnel-junction (TJ)

LEDs with different device areas (linear scale). The fitted lines (in

black) used to extract the turn-on voltage are shown in the linear plot.

(b) On-wafer electroluminescence spectra of a TJ-LED at a low current

density to high current densities. (c) Electroluminescence peak shift

plot showing the peak shift for current densities from 23 A cm-2 to 943 A

cm-2. Inset of (c) shows an optical micrograph of the device under

operation.

At the lowest current density where emission can be detected (23 A cm-2), peak electroluminescence is 548 nm, corresponding to a photon energy of 2.27 eV. As current density increases, emission shifts to 518 nm due to band filling and polarization charge screening.

To analyze voltage loss due to injection, we have plotted the operating voltage as a function of photon energy. This shows that our LEDs have operating voltages very close to their photon energies. When we compare this observation to previous accounts of green LEDs in the literature (see Figure 4), we find that our values are significantly lower than those previously reported. We therefore conclude that the lowered barriers from the reversed polarization deliver a significant reduction in the turn-on voltage.

Figure 4. Benchmark plot showing the forward-voltage drop at 20 A cm-2

or 35 A cm-2 for III-nitride LEDs from blue to yellow. The red line

represents the lowest theoretical voltage drop, Vf =hv1, where hv1 is the

photon energy and Vf is the forward voltage.

While the absolute external quantum efficiency of our LEDs is low, likely due to the impact of MBE growth conditions on the internal quantum efficiency of the wells, our work is still an important breakthrough – the measurements of the voltage drop provide convincing proof that the introduction of a reverse polarity p-down architecture improves the injection of carriers into an LED, and thereby reduces its operating voltage. We believe that this reduction to the operating voltage will have significant impact on future display and lighting applications employing longer wavelength emitters. What’s more, the switch to an n-type region above the LED could unleash several benefits associated with higher-level integration of other electronic devices, such as Schottky diodes and transistors. We view our design and demonstration of efficient tunneling-based, p-down LEDs as providing a framework for exploring other designs, including longer-wavelength LEDs and novel, multiple-active-region LEDs.

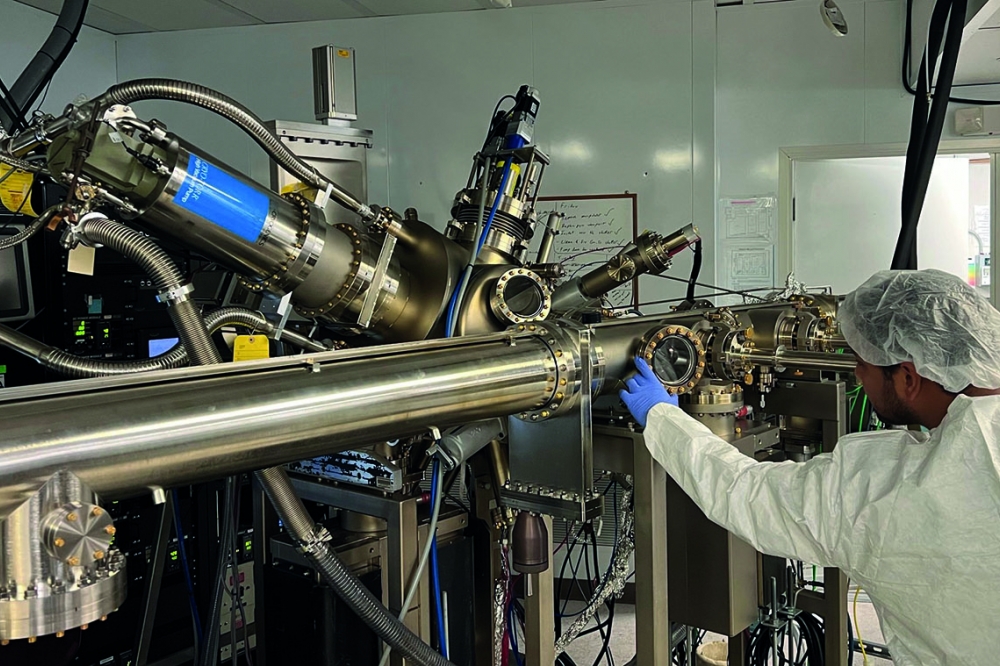

On-wafer LED measurement set up.

Further reading

† F. Akyol et al. “Suppression of electron overflow and efficiency droop in N-polar GaN green light emitting diodes” Appl. Phys. Lett. 100 111118 (2012)

† F.Akyol et al. “Low-resistance GaN tunnel homojunctions with 150 kA/cm2 current and repeatable negative differential resistance” Appl. Phys. Lett. 108 131103 (2016)

† S.I. Rahman et al. “III-Nitride p-down green (520 nm) light emitting diodes with near-ideal voltage drop” Appl. Phys. Lett. 121 021102 (2022)

† H Turski et al. “Polarization control in nitride quantum well light emitters enabled by bottom tunnel-junctions” J. Appl. Phys.125 203104 (2019)