BluGlass secures $10.2M funding

Funds will be used to scale product delivery and expand laser offering to address new markets

Semiconductor developer BluGlass has secured $10.2 million in commitments from international and Australian institutional and sophisticated investors via a strongly supported share placement at an issue price of $0.06 per share. BluGlass will also undertake a non-renounceable Entitlement Offer to raise up to a further $2.7 million, enabling the company’s shareholders to participate on the same terms as the Placement.

Funds will be used for additional fab equipment to scale and speed product delivery, and expand BluGlass’ product offering to increase market competitiveness.

BluGlass chair James Walker said: “The support of institutional and sophisticated investors provides confidence in our technical and commercial roadmaps, and we are pleased to welcome new and returning global funds to the register. The BluGlass team remains focused on growing market traction, generating recurring revenues, and delivering value for our customers and shareholders.”

BluGlass CEO Jim Haden added: “This funding will accelerate our commercialisation progress with advanced in- house capabilities enabling us to scale and speed our product delivery to meet significant unmet market needs. The market’s response to our initial products has been very encouraging, and we are looking to capitalise on this momentum to rapidly build our customer base and laser diode bookings.

“We’re also investing in our GaN laser offering to leverage our competitive advantages, address new markets and applications, and take market share. At the same time, we’re continuously improving the power and efficiency of our products toward world-class standards which will support growth in orders and revenue.

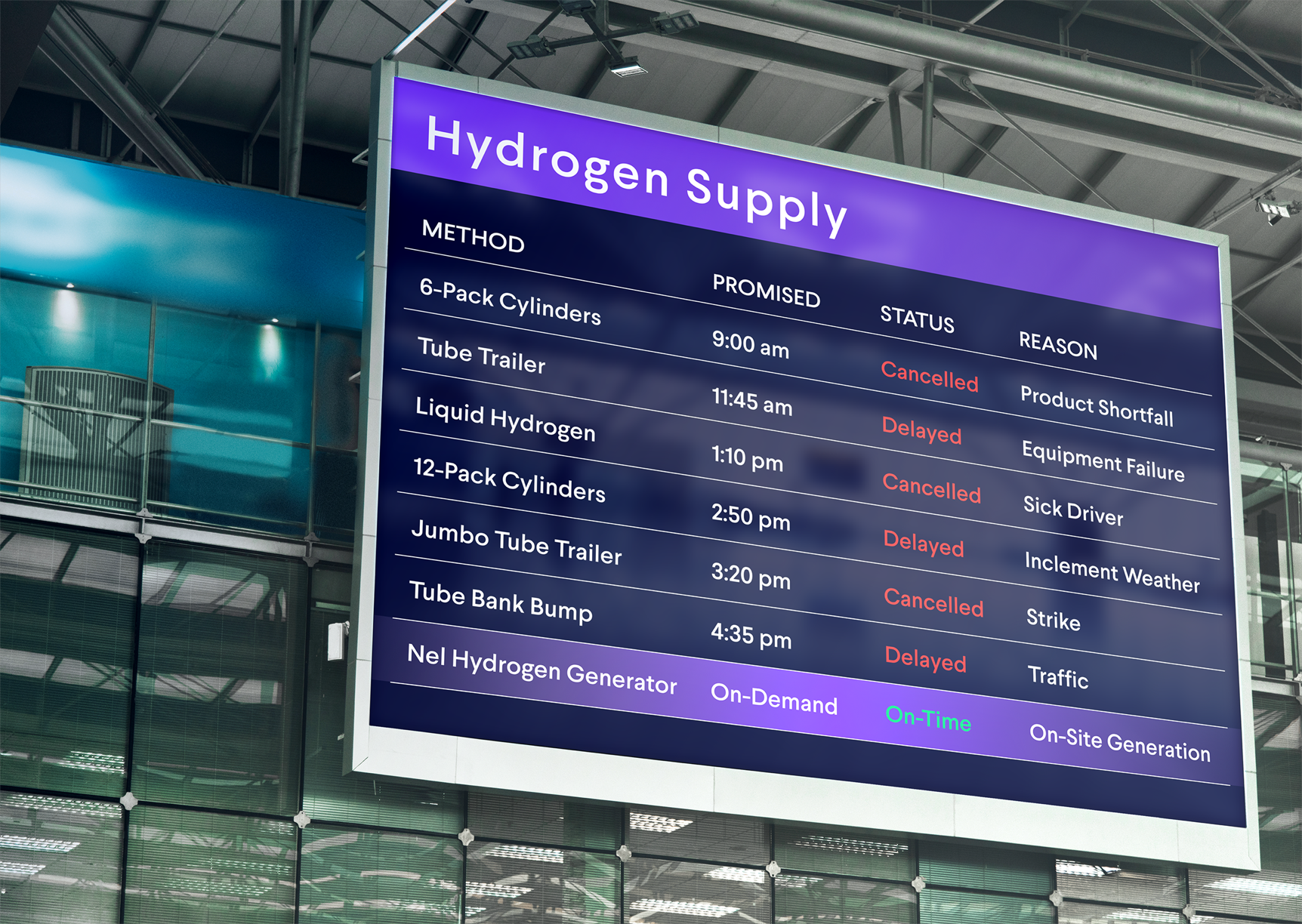

Secure Your Hydrogen Supply

A study supply of high-purity hydrogen is critical to semiconductor fabrication. Supply chain interruptions are challenging manufacturers, leading to production slowdowns and stoppages. On-site hydrogen generation offers a scalable alternative for new and existing fabs, freeing the operator from dependence on delivered gas.Plant managers understand the critical role that hydrogen plays in semiconductor fabrication. That important job includes crystal growth, carrier gas, wafer annealing, and in the emerging Extreme UV Lithography (EUV) that will enable new generations of devices. As the vast need for semiconductors grows across all sectors of world economies, so does the need for high-purity hydrogen.

Take control with Nel on-site hydrogen generation.

Read more

.jpeg)