Powering the exploration of Jupiter

The instruments on-board the latest mission to Jupiter are drawing energy from a vast array of solar cells produced by Azur Space Solar Power

BY RICHARD STEVENSON, EDITOR, CS MAGAZINE

Think of solar cells and you probably picture devices operating in sunny climes, where they convert intense rays into lots of renewable energy. But that’s not their only task. Photovoltaics are also deployed on extra-terrestrial missions, where the intensity of sunlight can be far lower than it is on Earth.

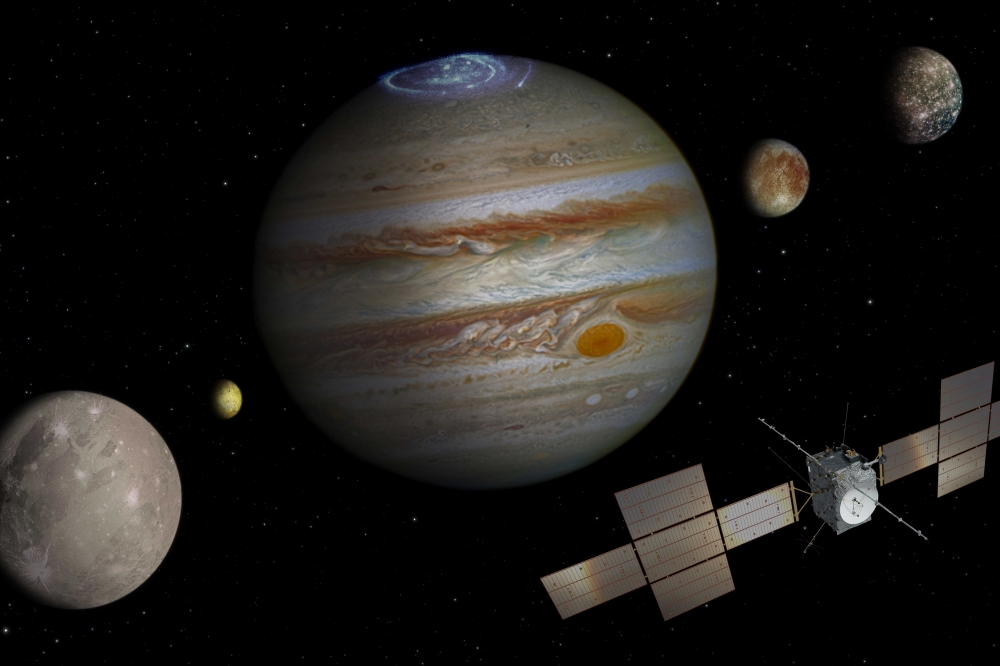

Right now, a spacecraft equipped with solar panels is hurtling through space on a mission to Jupiter, where it will study this planet and its moons. On this voyage, operated by the European Space Agency, detailed observations will be made of this planet and its three ocean-bearing moons by scientific instruments powered by photovoltaic panels, which will receive solar radiation with an intensity around just 3.5 percent of that experienced by satellites orbiting the Earth.

Providing power for this latest mission to Jupiter, known as JUICE – JUpiter Icy Moons Explorer – is a vast array of triple-junction solar cells, produced by Azur Space Solar Power, now a subsidiary of 5N Plus. These cells are considerably more efficient than those made from silicon, as well as being more robust to bombardment from high energy particles.

Having cells that excel in converting the Sun’s rays into electricity is particularly important at low levels of incident solar radiation, because when the intensity falls, there’s a linear reduction in current and a logarithmic decline in voltage. “So just by having a lower intensity, you get a lower efficiency of the solar cell,” explains Wolfgang Guter, Director of Marketing at Azur.

Another challenge facing these solar cells that are on a mission to Jupiter is that they face particularly heavy bombardment from high-energy electron and proton radiation under continuously low temperatures. This fluence is more than an order of magnitude higher than that for a cell orbiting the earth, and roughly equal in value to that facing a solar array travelling by electrically powered propulsion to a geostationary orbit.

“However, the damage to solar cells at Jupiter is much more severe than the damage caused by the same fluence in an orbit around Earth,” remarks Guter. He says that the damage is about 20 percent greater, due to the removal of self-annealing that stems from the lower temperature.

Fortunately, the lower temperature found on the JUICE mission, typically around -120 °C in the sun, also has an upside. As temperature falls, cell efficiency rises to 35 percent, a value considerably higher than that for a satellite orbiting the Earth.

A colossal undertaking

Azur’s contribution to the JUICE program is the supply of around 24,000 high-efficiency cells that form a 85 m2 solar array, which produces just enough power for the complete duration of the mission. To put that size in context, arrays on commercial constellation satellites typically cover just 10 m2, while those on large geo-stationary communication satellites, producing around 27 kW of power, are up to 70 m2.

For all satellites, every cell is tested before it is deployed. However, for the mission to Jupiter cells are subjected to greater scrutiny, with additional testing covering low light operation conditions.

Fabrication of the cells involves the growth of complex heterostructures on substrates, prior to the processing of these epiwafers into devices. The latter steps include metallisation and the addition of an anti-reflection coating. For the JUICE programme, once testing identified the cells with sufficient performance, they were sent to Leonardo, which added glass and interconnects to create solar panels. These panels were integrated to the spacecraft by Airbus.

Given the extensive prelaunch work, it is not that surprising that the development of the cells for this spacecraft, which set off for Jupiter this April, began ten years ago. Back then solar cells with an area of 30 cm² used for JUICE were considered state of the art.

Comprehensive testing of this product determined that it is free from specific thermally activated defects within this heterostructure, even at temperatures as low at around -120 °C. That’s a major asset, at it ensures a low resistivity, crucial for high-performance in space. The power bus on satellites typically requires 50-100 V to operate, while the open voltage produced by each cell is around 3.5 V, so they are wired in series. This scales the voltage, but current is limited by the cell with the lowest current.

The voyage to Jupiter is rather complex, exploiting multiple gravitational slingshots to reduce the time of the journey with a route that includes a flyby of Venus. Near that planet close to the Sun the cell temperature could reach 160 °C, so to prevent cells from overheating, the panels are orientated at an angle to the Sun’s rays.

As it will be 2031 by the time the spacecraft reaches Jupiter, those at Azur will have to wait several years before claiming that this mission confirms the capability of their cells. However, that lack of practical validation is not stopping them from winning contracts on other demanding space exploration missions, including NASA’s Europa Clipper mission, which will investigate whether Jupiter’s icy moon could have conditions suitable for life. Guter attributes securing that contract to a thorough understanding of the performance and the degradation mechanisms of their solar cells under low intensity, low-temperatures conditions.