Toshiba launches 650V SiC Schottky barrier diodes

New devices use 3rd generation process technology to enhance efficiency

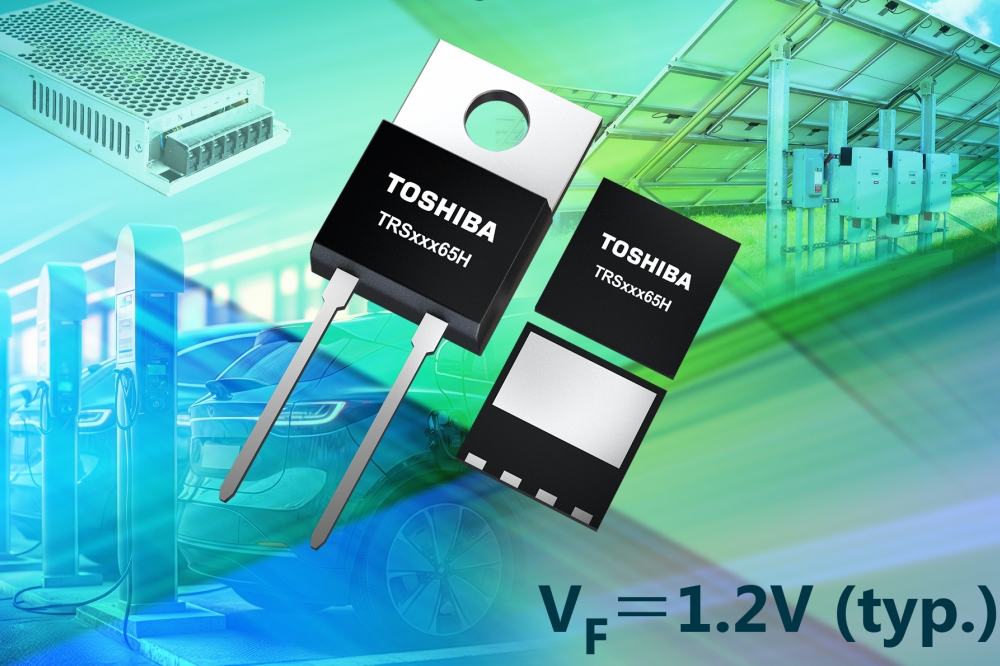

Toshiba has announced the launch of twelve 650V SiC Schottky barrier diode (SBDs) based upon the latest 3rd generation technology. The new devices are for use in efficiency-critical industrial equipment applications including switching power supplies, electric vehicle (EV) charging stations and photovoltaic (PV) inverters.

Known as the TRSxxx65H series, the new devices use new Schottky metal. The 3rd generation SiC SBDs chip optimises the junction barrier Schottky (JBS) structure of the 2nd generation products, thereby lowering the electric field at the Schottky interface and reducing leakage current – delivering enhanced efficiency.

The 3rd generation devices achieve excellent low forward voltage (VF) of 1.2V (typ.). This represents a 17 percent reduction when compared to 2nd generation products. The new 3rd generation products have improved the trade-offs between VF and total capacitive charge (QC) which is typically 17nC for the TRS6E65H.

Also, the VF and reverse current (IR) ratio is improved compared to 2nd generation products with the TRS6E65H achieving a typical IR value of 1.1µA. All of these improvements reduce power dissipation and contribute to higher levels of efficiency within end equipment.

Devices within the TRSxxx65H series are capable of forward DC currents (IF(DC)) up to 12A and square wave non-repetitive surge currents IFSM up to 640A. Seven of the new devices are housed in TO-220-2L packages while the remaining five are provided in compact and flat DFN8×8 SMD packages.