UK spin-out to commercialise perovskite process

Aerosol-assisted solvent treatment promises lower defects, higher efficiency, and stability across various compositions, device structures, and areas

Aerosolar, a spin-out from Queen Mary University of London, aims to commercialise a new aerosol-based treatment for making perovskite solar cells more affordable and efficient.

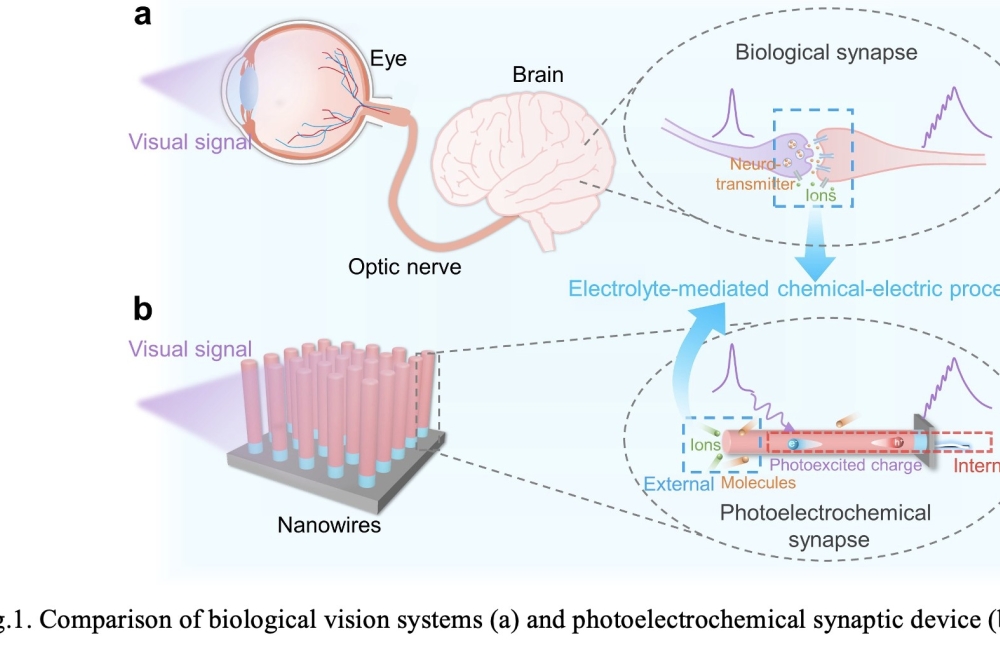

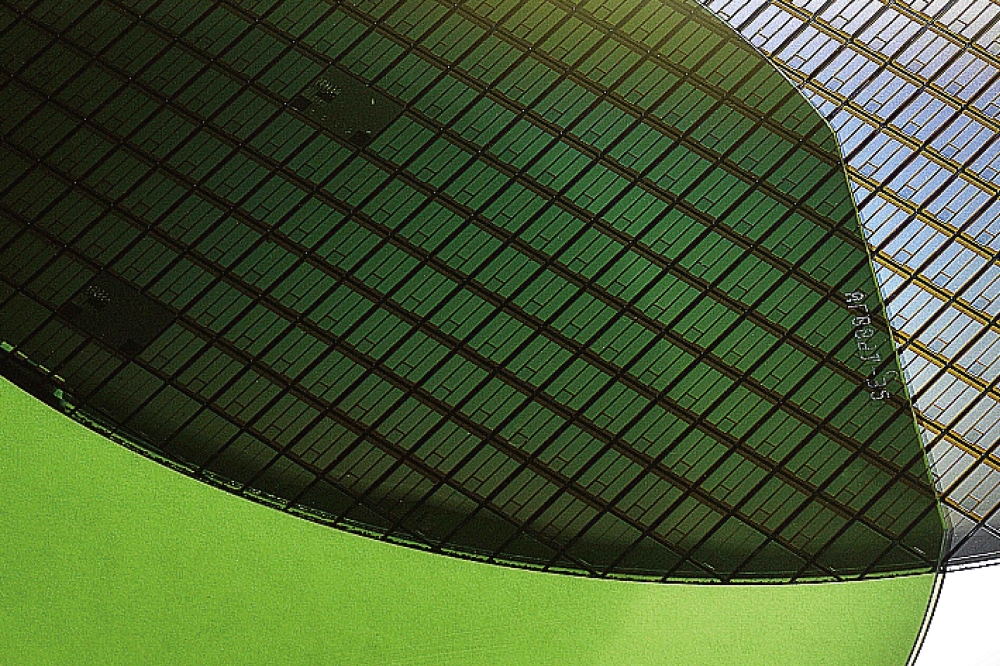

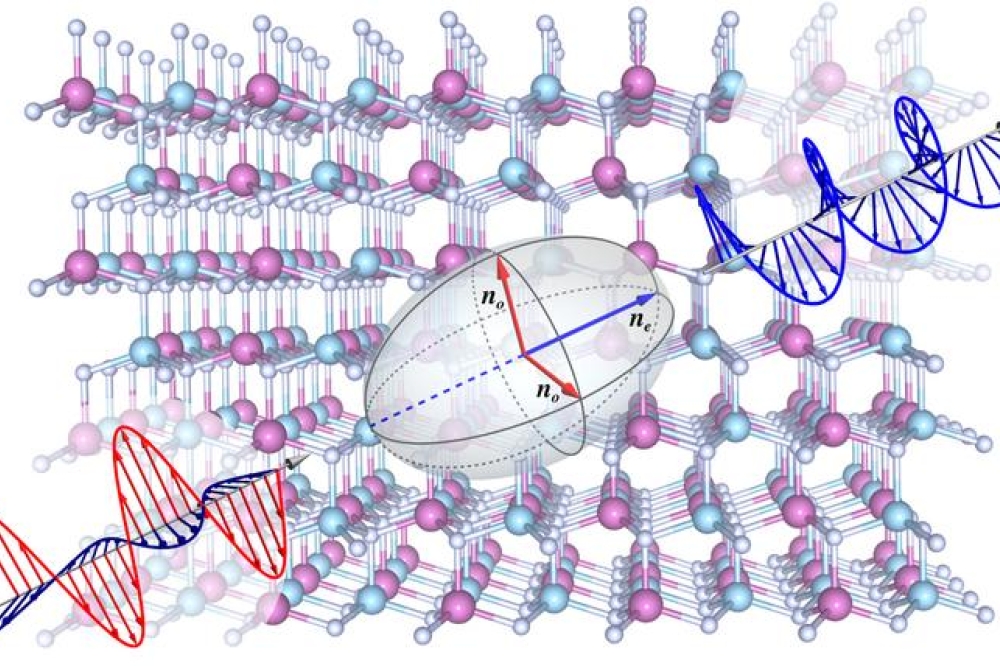

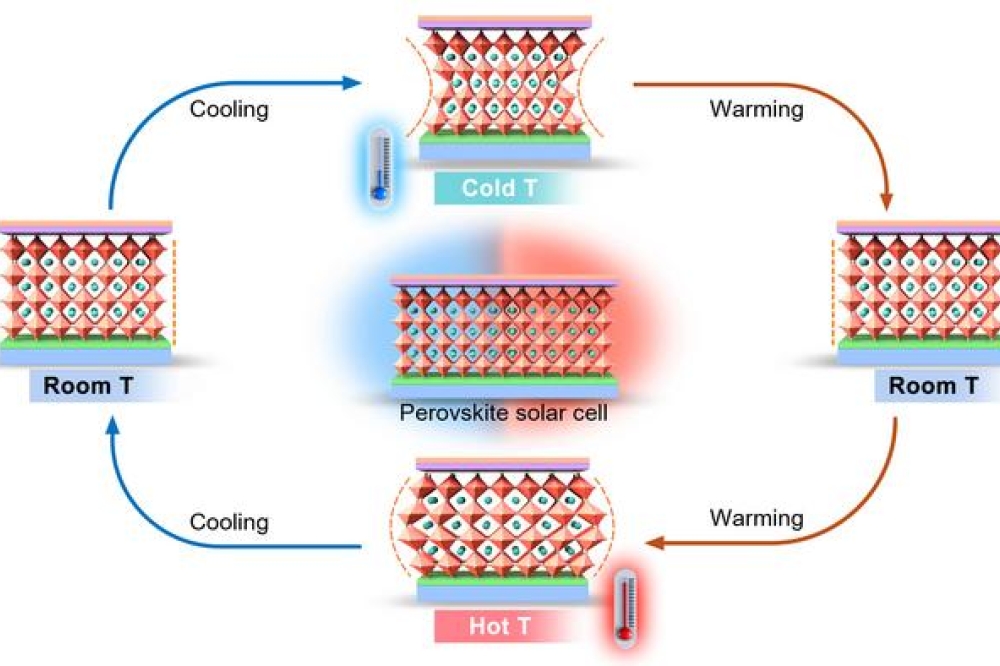

Perovskite solar cells now boast a solar energy conversion efficiency of over 25 percent. However, challenges persist. The low-temperature, solution-based nature of the manufacturing process leads to a high number of flaws in the material, especially when manufactured over large areas. The cells themselves are also susceptible to decomposition when exposed to moisture and oxygen, which severely limits perovskite’s commercial viability.

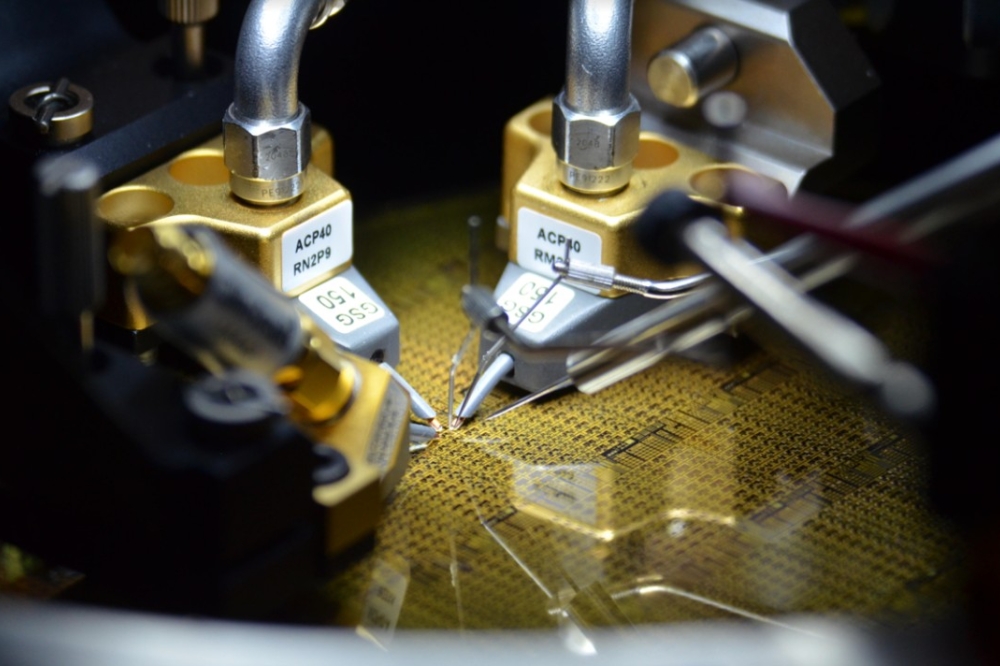

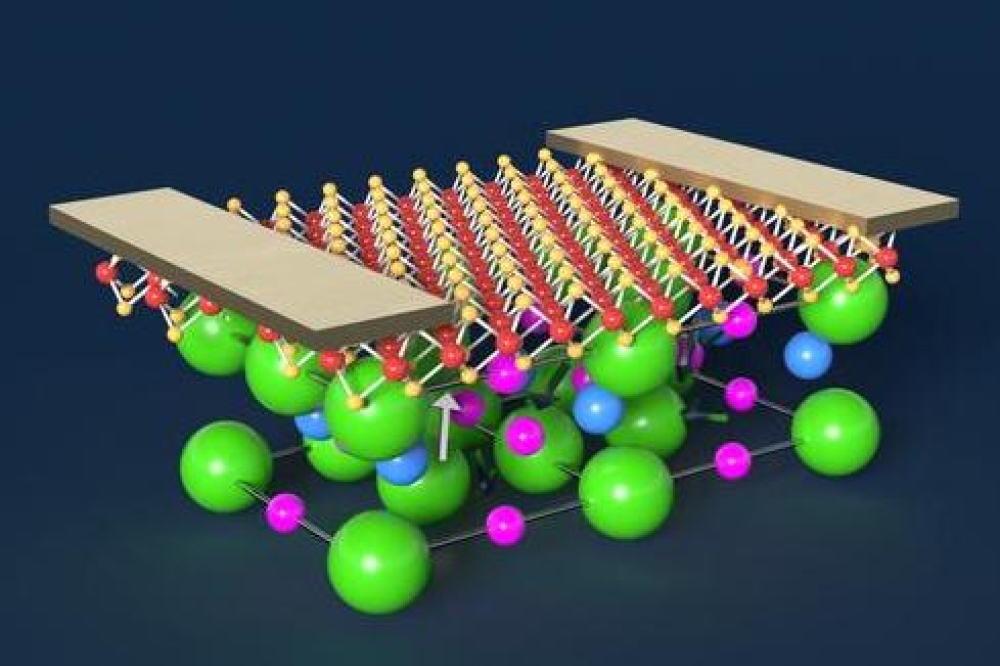

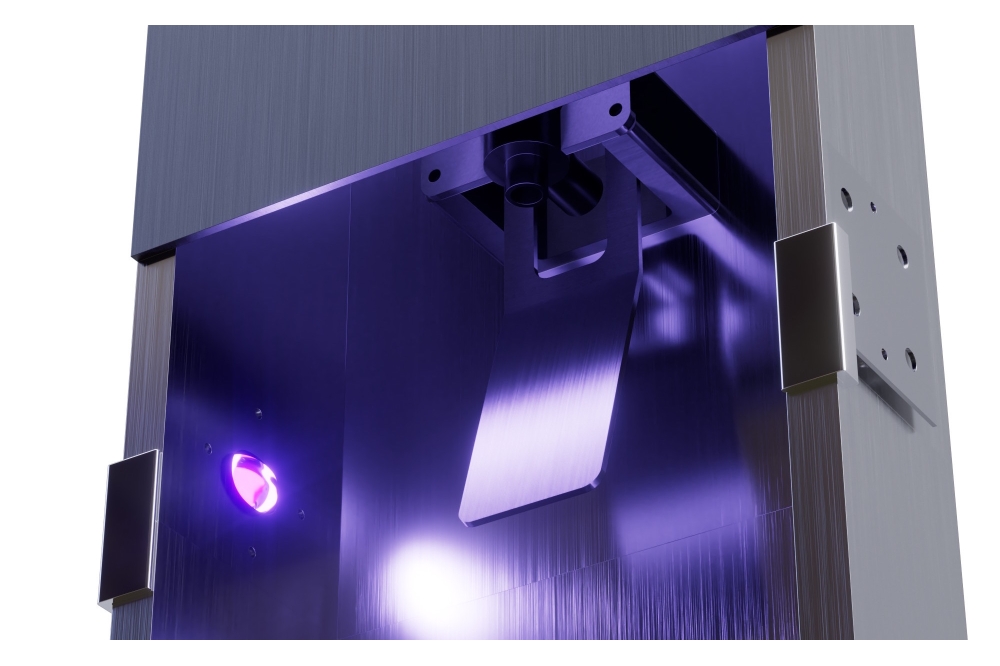

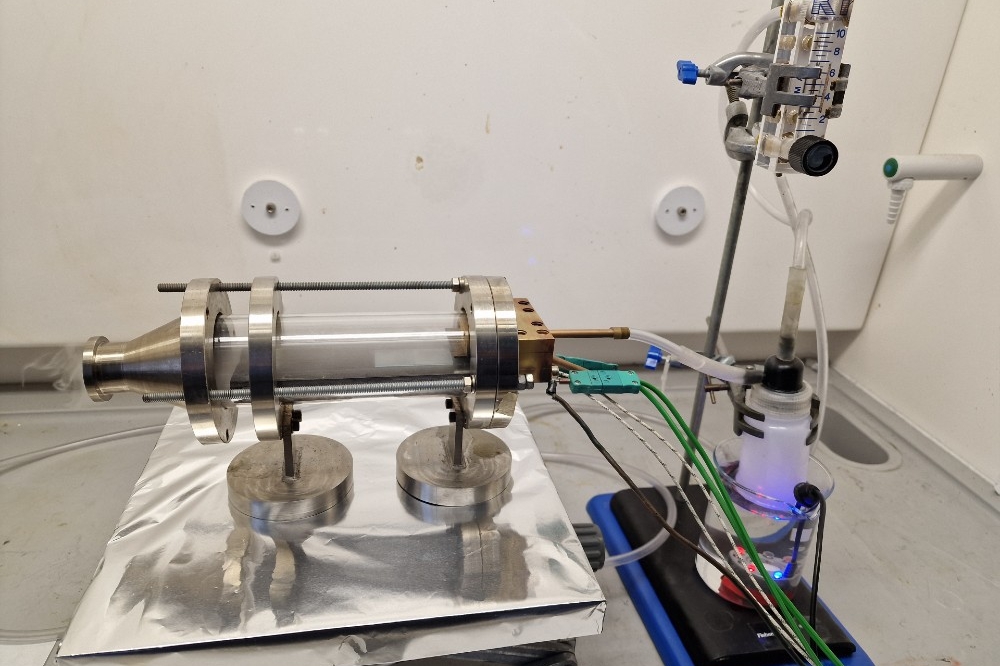

The aerosol-assisted solvent treatment has been developed by professor of Energy Materials and Devices at QMUL Joe Briscoe and his team. It involves passing dimethylformamide solution (alone or with added methylammonium chloride) over a surface in a controlled manner before passing through a reactor containing the heated perovskite sample. This takes no more than five minutes and can also facilitate processing at a lower temperature (100 degrees C) compared to direct thermal annealing.

According to Briscoe, this approach significantly enhances the grain growth of perovskite cells, reducing local defects and improving overall uniformity. The treated perovskite cells also exhibit remarkable performance improvements, with increased efficiency and stability across various compositions, device structures, and areas. It also makes these cells more affordable and easier to mass-manufacture.

Aerosol-enhanced perovskite cells can be printed onto plastic sheets, enabling these cells to be implemented in new ways, such as indoor locations, self-powered consumer electronics, car ports, building exteriors, and even integration into electric vehicles.

Beyond this, perovskites can be turned to absorb the blue end of the spectrum, where a lot of the energy loss comes from in silicon solar cells. These can then be stacked on top of silicon cells to make a ‘tandem’ design, boosting the overall efficiency of the solar panels to nearly 30 percent, according to Briscoe.

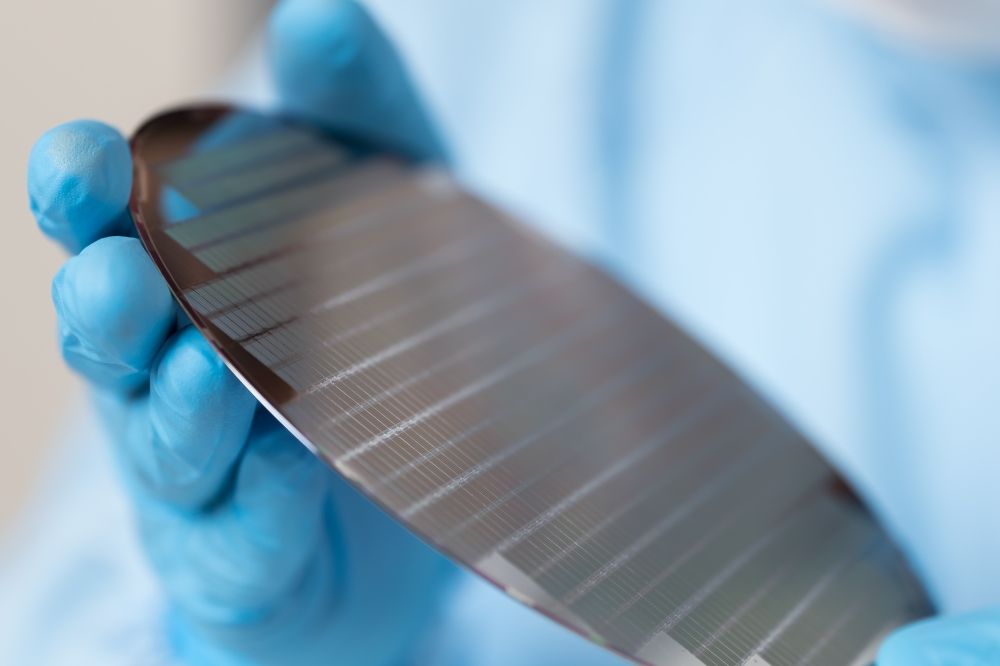

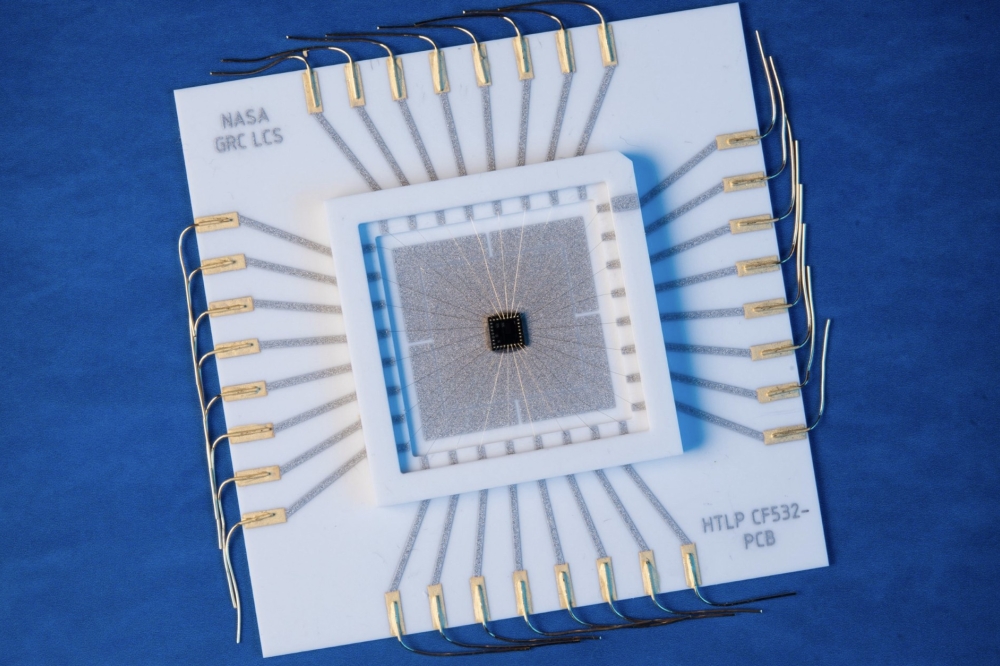

Looking ahead, Briscoe's team is conducting further tests to assess the long-term effectiveness of this process and its scalability for commercial applications. The plan is to optimise the aerosol-assisted solvent treatment in a large-area reactor, paving the way for the development of cost-effective, lightweight, and flexible solar cells at a commercial scale.

To this end, the spin-out AeroSolar has received £50,000 from Innovate UK to build a large-scale reactor, which has now been completed and is undergoing testing. Th team is collaborating with perovskite solar cell manufacturers and attracting interest from investors.