Barcelona institute orders Corial PECVD system

IMB-CNM-CSIC has ordered a 300mm system for the research and development of advanced micro and nano integrated systems

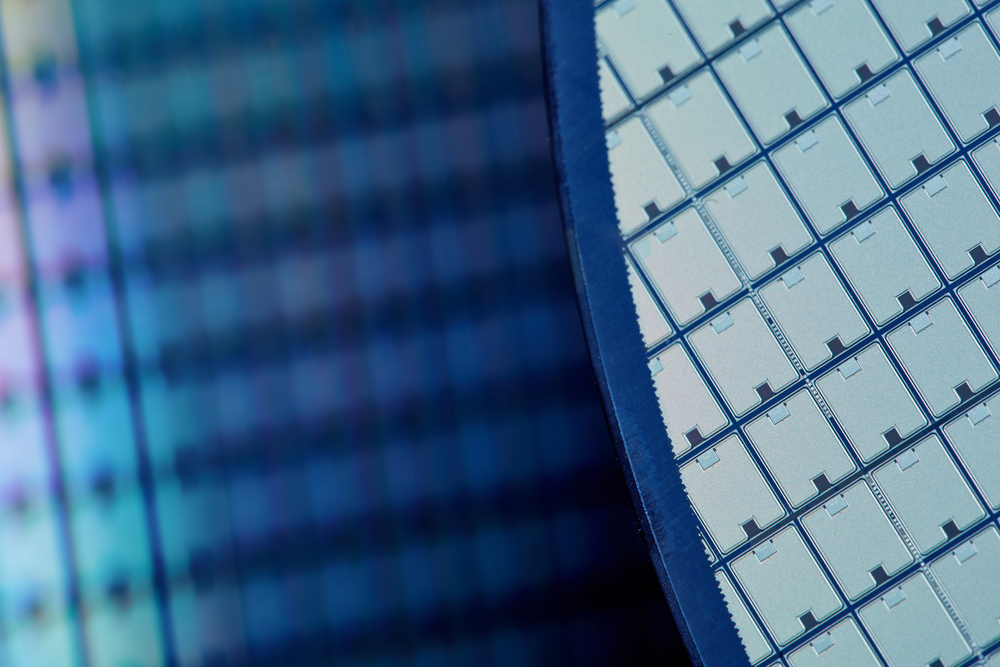

Corial, the plasma processing equipment manufacturer and plasma process developer, has announced that Institute of Microelectronics of Barcelona (IMB-CNM-CSIC) has ordered a 300 mm PECVD system (Corial D350L) for the research and development of advanced Micro/Nano integrated systems.

Headquartered in Barcelona, IMB-CNM-CSIC is a leading European research centre, founded 1985. The research activities of IMB-CNM-CSIC are dedicated to Micro/Nano Integrated Systems: miniaturised electronic systems which include sensing and/or actuating capabilities in addition to electronic information processing, power management and external interfaces.

"Corial D350L PECVD tool is uniquely positioned to provide a wide process window," said Elsa Bernard-Moulin, marketing manager of Corial. She also said that the addition of a flexible liquid source delivery module with capacity for up to three precursors achieves new levels of process flexibility towards two key applications: highly conformal deposition of oxide films; and deposition of silicon oxide doped with B or P for the formation of borophosphosilicate glass layers.

The Corial D350L is a production-ready PECVD system built on a 300 mm platform, with single wafer and multi-wafer batch capability. The PECVD system is based on Corial's proprietary technology featuring isothermal, pressurised reactor, which provides rapid and uniform thin film deposition on wafers up to 300mm in diameter.

Typical process performances for thick SiO2 film deposition on 100 mm Si wafer are: thickness up to 5 µm without intermediate plasma cleaning; high deposition rate up to 300 nm/min; and uniform WIW thickness (3 percent) and RI (0.005)

Based on a high temperature, dual pumped configuration, the Corial D350L PECVD system also offers efficient plasma cleaning at operating temperature, with no corrosion of mechanical parts. The system can operate for years without the need for manual cleaning.