Veeco installs 100th automated MBE system

GEN10 MBE System at Silanna Semiconductor in Australia will be used for advanced oxide R&D for optoelectronic devices

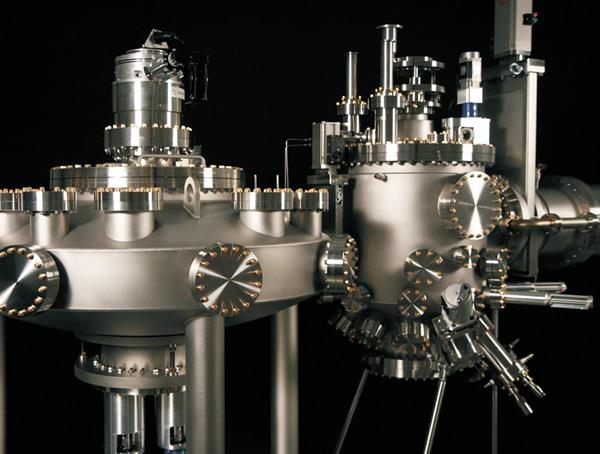

Veeco has completed installation of its 100th automated MBE system. The installation of Veeco's GEN10 MBE System last month at Silanna Semiconductor in Australia marks this significant company milestone. The company also operates a Veeco Dual GEN200® MBE System for production of advanced nitride compound semiconductor devices including UV-LEDs.

"Veeco has earned a reputation for consistently developing innovative and reliable MBE technology from research scale to production," said Petar Atanackovic, chief scientist of Silanna Semiconductor.

"The flexibility and deposition capability of the GEN10 system will enable us to develop new materials at the atomic level allowing us to exploit new quantum properties. Veeco's technology portfolio and leadership in MBE systems provides us with a clear path to easily scale to volume production in the future."

Silanna is using the GEN10 system for advanced oxide research and development for optoelectronic devices. The GEN10 is built upon almost 20 years of cumulative automation knowledge and derived from the company's proven production MBE systems.

Adopted by numerous leading corporations, institutions and universities for all major MBE applications, many customers choose the GEN10 because of its flexibility, which allows them to configure the system based on their application. This gives customers optimal performance with any material set, including those related to III-V group elements, oxides and nitrides.

"Silanna has achieved remarkable results on its previous MBE systems and Veeco is honored to celebrate this momentous accomplishment in our company history in partnership with Dr. Atanackovic and the Silanna team," said Gerry Blumenstock, vice president and general manager, Veeco MBE Products.

"As our customers explore novel materials and new applications, they can rely on Veeco to deliver innovative MBE systems, sources and components for use in complex R&D, as well as high-volume production environments."