KAUST team heats up MOCVD

A chemical reactor that operates at extremely high temperatures is being developed by KAUST (King Abdullah University of Science and Technology) and could improve the efficiency and economy of a commonly used process in the semiconductor industry, with flow-on benefits for Saudi Arabia's chemical industry. They published the latest results in the Journal of Crystal Growth.

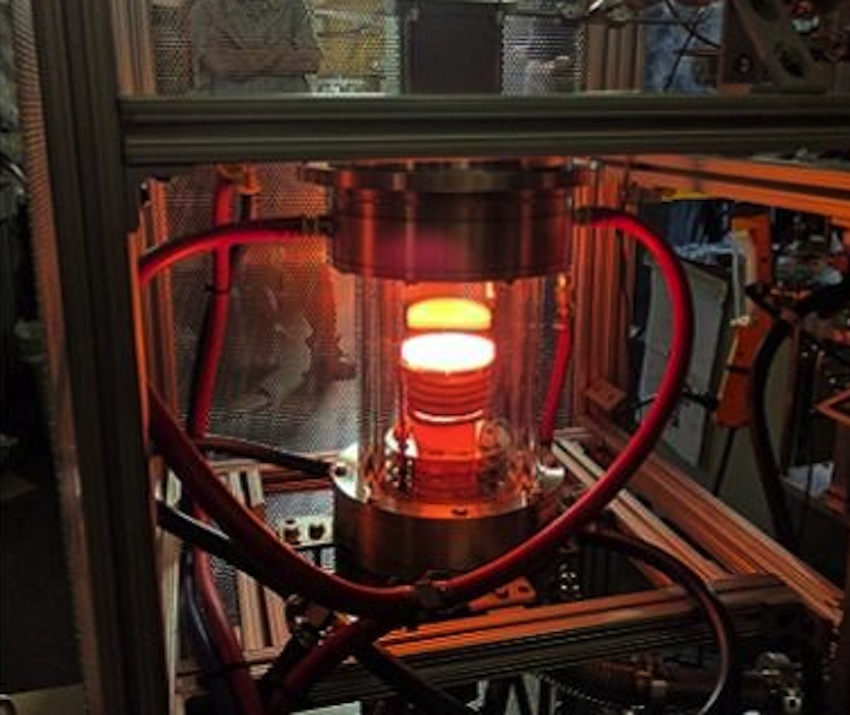

Kuang-Hui Li and a team led by Xiaohang Li at KAUST are developing an MOCVD reactor that can efficiently operate at extremely high temperatures to create high-quality BN and AlN materials and devices particularly promising for flexible electronics, ultraviolet optoelectronics and power electronics.

The epitaxy of high-quality BN and AlN have been a huge challenge for the conventional MOCVD process, which usually operates below 1200deg. Epitaxy of these materials responds best to temperatures over 1600 degC; however, the most common resistant heaters are not reliable at these temperatures.

Although induction heaters can reach these temperatures, the heating efficiency of the conventional design is low. Because the wasted energy can overheat the gas inlet, it must be placed far away from the wafer, which is problematic for high-quality BN and AlN due to particle generation and low use of organic molecules.

The KAUST team has developed an innovative and low-cost induction heating structure to solve these problems. "Our design can help greatly improve uniformity for up to 12-inch wafers and reduce particle generation, which is crucial for high-quality material and device fabrication," says Kuang-Hui. "It also allows us to discover new materials."

The results show significant increase in heating efficiency and reduction in wasted energy, according to the team. "This equipment research involves many disciplines and is highly complex. However, history has shown that equipment innovation is the key to scientific breakthroughs and industrial revolution," says Xiaohang Li. "A goal of the research is to set up MOCVD manufacturing activities that can be integrated into the huge chemical industry of Saudi Arabia."

'Induction-heating MOCVD reactor with significantly improved heating efficiency and reduced harmful magnetic coupling,' by Kuang-Hui Li et al; Journal of Crystal Growth, Volume 488, 15 April 2018