Ready or not, AI is here to stay

The combination of AI and machine learning, in conjunction with automation, optimisation, and exception management, holds the key to improving the running of every compound semiconductor fab.

BY JON HERLOCKER FROM TIGNIS

In today’s world, everywhere we look we see claims of how Artificial Intelligence (AI) will disrupt our world. If you take these assertions at face value, you might start thinking that AI is some kind of magic that will solve almost all of humanity’s issues. However, that’s not the case. To ensure the successful application of AI, appropriate inputs and a level of creativity are mandatory. The reality is that the successful implementation of AI in a manufacturing environment is a combination of mathematics, science, and innovation.

While previous waves of AI enthusiasm have failed to deliver broad market benefits, today’s and tomorrow’s AI is certain to play a critical role in compound semiconductor manufacturing. Companies that successfully adopt either AI, machine learning (ML), or both of them before their peers will benefit from significant competitive advantages. According to management consultant McKinsey, AL/ML currently contributes between $5 billion and $8 billion to annual earnings at semiconductor companies – and that figure is forecast to increase ten-fold over the next two-to-three years.

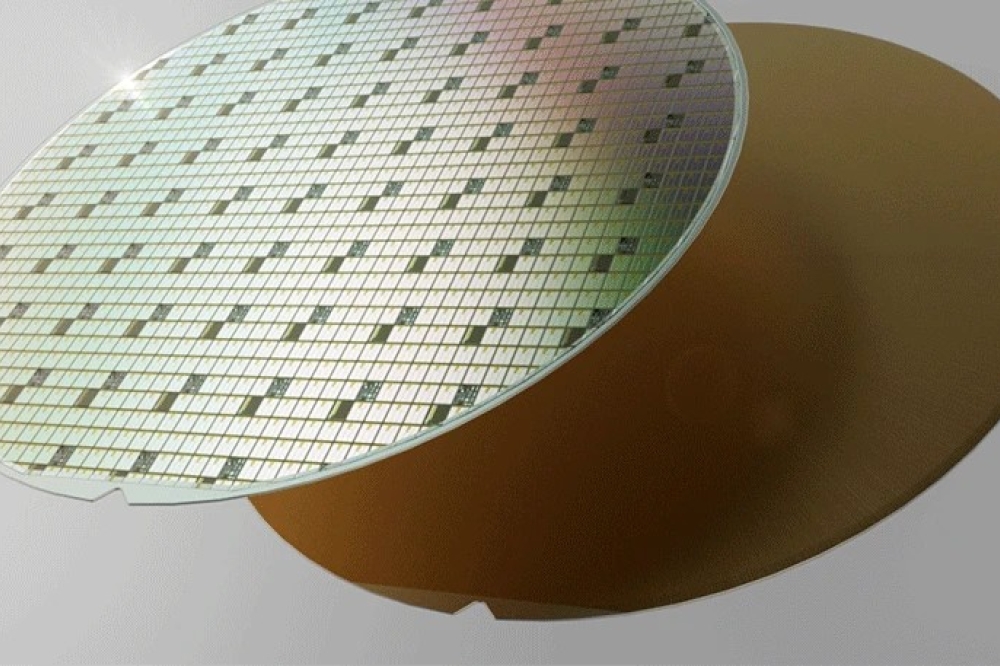

Leading-edge device makers manufacturing at 10 nm and below are already years into their journey of deploying AI. For these chipmakers, their revenue and market valuation are justifying investing billions of dollars into custom-built AI solutions for their state-of-the-art fabs.

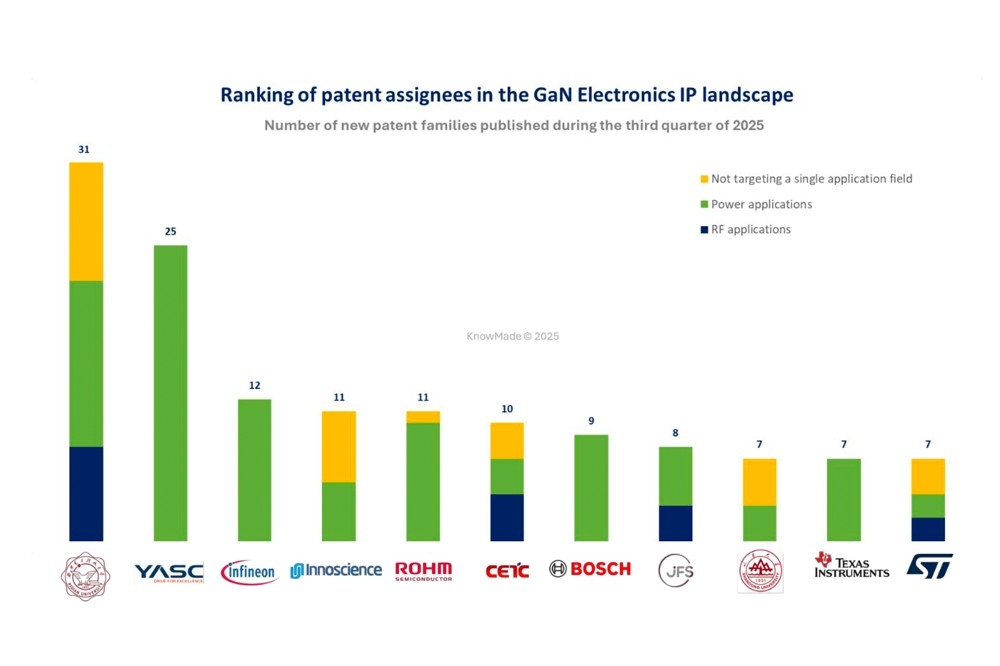

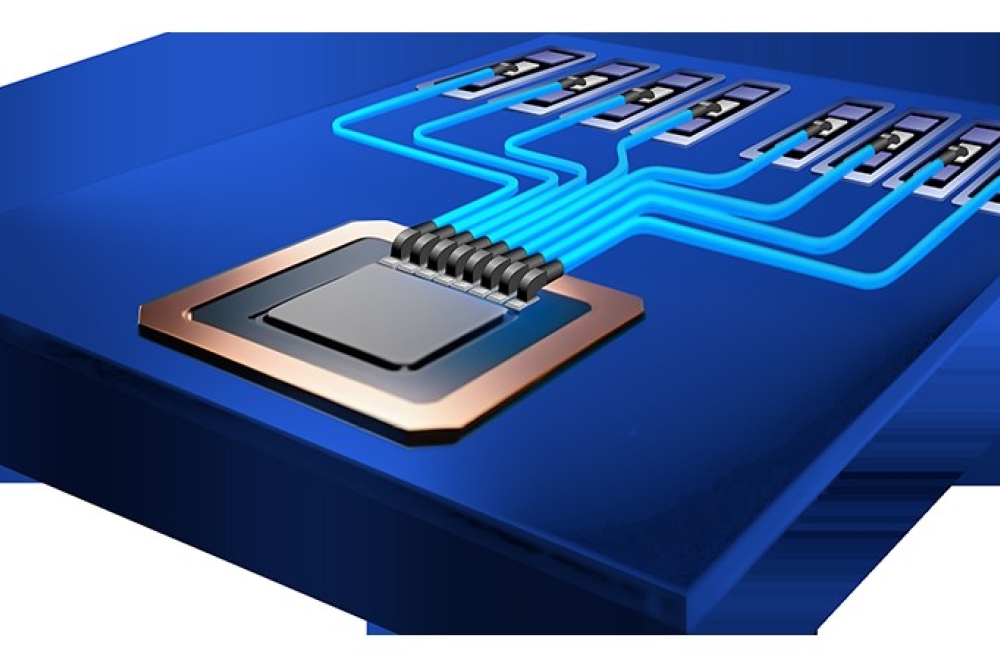

Despite manufacturing at mature process nodes, compound semiconductor fabs have much to gain from AI and ML (see Figure 1). That’s because successful AI/ML projects focus on business value metrics that matter.

One famous formulation of business value in a manufacturing facility is based on Goldratt’s Rules of Flow, which postulates that the two most important metrics for any factory are throughput and cost. AI/ML can directly improve both. Impacts include enhancing throughput by increasing yield and uptime, and trimming operating costs by reducing scrap and increasing engineering productivity.

It is possible to significantly improve throughput and cost metrics via AI/ML without having to invest millions of dollars of capital on new hardware. And if you have a leadership role in a compound semiconductor fab, part of your job in the next decade will be deciding where and when to invest in ML.

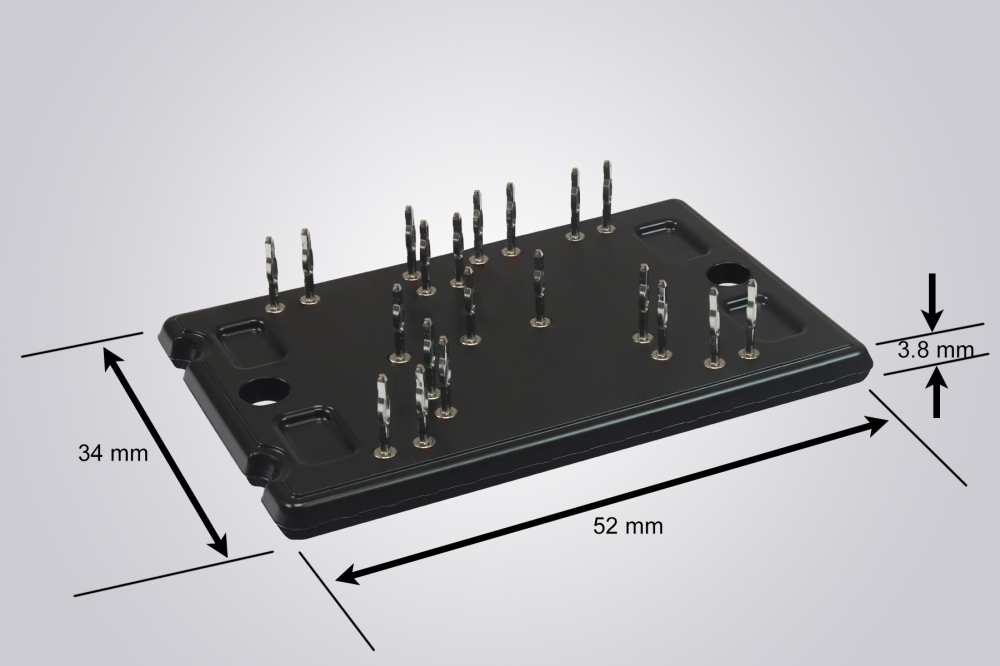

Figure 1. Decoding AI/ML terminology. A Venn diagram of the most popular ML tools.

In addition to the core business properties outlined

already, there are two additional business considerations of note: agility and

resiliency.

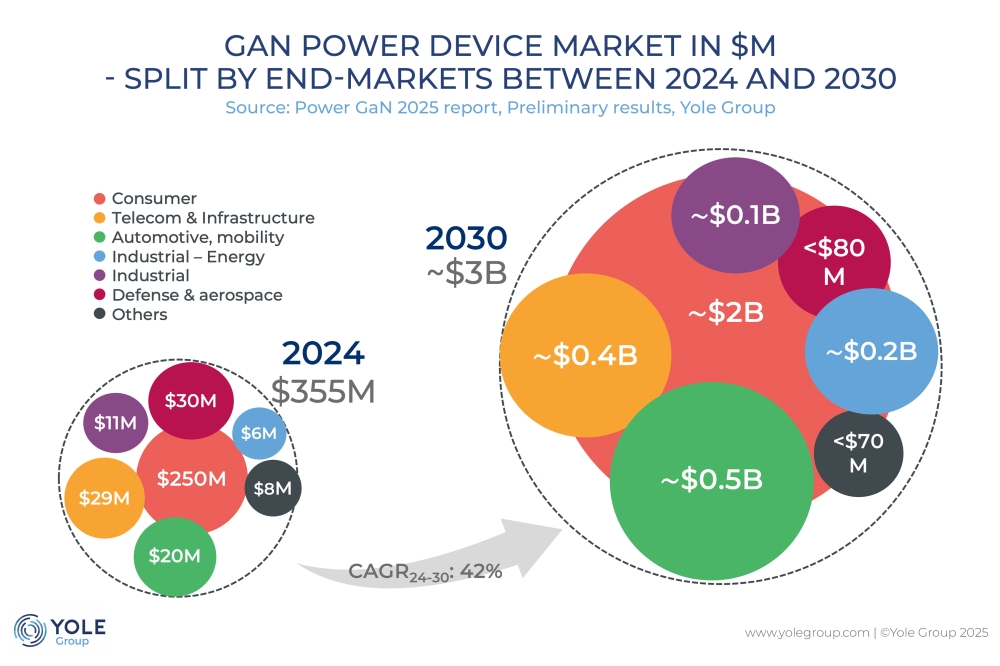

Agility is the ability of a business to adapt to changes more quickly. How fast can you respond to changes in raw materials due to obsolescence? Or a change in product mix due to a market shift? And what about a dramatic change in workforce availability? There could also be market changes – like we are seeing with the opportunity in electric vehicles for makers of SiC and GaN power electronics.

When it comes to resiliency, this reflects the ability of a business to survive or even thrive in the face of losses – those of key personnel, equipment, customers, and facilities.

To understand where you should be considering applying AI/ML to improve productivity, agility and resiliency, you need to think about automation, optimisation, and exception management.

The first of these three considerations, automation, is the reduction of human intervention in a process. Human intervention tends to take place when there is the need to make a decision, or there is a need for human dexterity. AI/ML is a great enabler of increased automation. Turn to automation when you have humans spending non-trivial time on repetitive tasks, from tweaking recipes all the way to updating spreadsheets.

Optimisation is about making the best possible decision from the available data. It becomes a true superpower when paired with automation, enabling the equipment in your fab to continuously adjust key parameters, so that it remains in an optimal range of operation. You should think about the times where you need to make human decisions regularly, and revisit the results of past decisions – for example, the parameters of your process recipes, your scheduling logic, or your preventative maintenance schedules.

The third consideration, exception management, is a core foundation of more advanced fabs (operationally, not by process node). While automation and optimisation are about creating increasingly predictable processes, even in the best fab environments, disturbances and exceptions happen. Equipment fails, software suffers from bugs, operators do unexpected things, material sometimes fails to meet specifications. As you automate more of your fab, how do you even know when something is wrong, or is about to go wrong? You should look to AI/ML to reduce exceptions, to better detect exceptions before they cause damage, and to diagnose and resolve exceptions more efficiently.

When we consider these three factors when applying AI/ML, one can sum it up as saying that more automation means less human intervention – lower cost, faster cycles, and more agility/resiliency. Meanwhile, optimising throughput and costs have direct and measurable business value, and exception management ensures that manufacturing processes remain stable and available, minimising exception cost. Automation, optimisation, and exception management all deliver direct revenue or cost benefits.

While AI is not magic, don’t dismiss it as a distraction. It will move the business needle. It will increase your wafer flow, it will reduce your operational costs, and it will also increase your fab’s agility and resiliency. There’s no doubt that AI and machine-learning will become a critical part of the compound semiconductor manufacturing world, with those successfully adopting AI early enjoying significant competitive advantages. For those that fail to appreciate AI, their oversight will be seen in inferior balance sheets.