Mitsubishi Heavy Industries to collaborate on wafer bonding

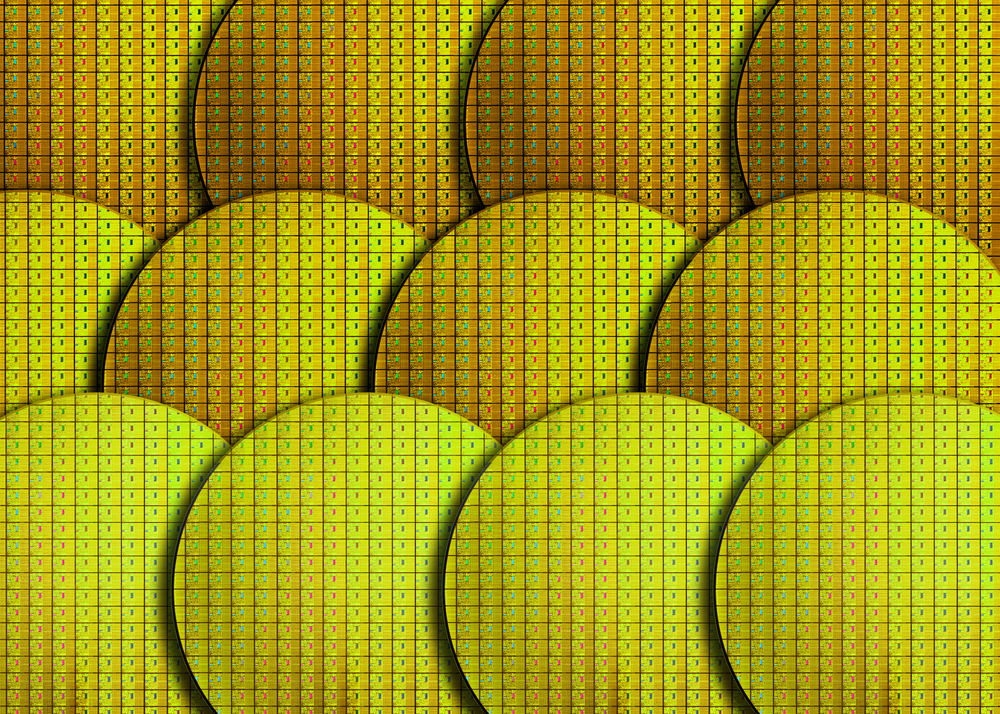

Mitsubishi Heavy Industries Machine Tools has concluded an agreement with D-process Inc, a chemical mechanical polishing company, to collaborate on bonding services performed using MHI's room-temperature wafer bonding machines.

Room-temperature bonding, which can be used on oxide dielectrics, compound semiconductors, glass, metals and ceramics, activates wafer surfaces by irradiating an ion or atom beam in a vacuum. Because no heat is applied, it is suited to bonding of materials having different coefficients of thermal expansion (CTE) as well as the manufacture of MEMS, which require very precise finishing, and biodevices, which cannot be heated.

The collaborative arrangement is aimed at putting in place an integrated service structure for polishing - including D-process's chemical mechanical polishing (CMP) - and room-temperature bonding as a way of advancing and expanding the company's semiconductor foundry operations.

The collaborative agreement calls for Mitsubishi Heavy Industries Machine Tool to perform bonding, using its own room-temperature bonding machines, of wafers that have undergone CMP and/or other surface smoothing processes at D-process on consignment from customers.

Mitsubishi Heavy Industries Machine Tool has offered room-temperature bonding services since 2014, including orders received from D-process. Going forward, further expansion can now be anticipated in the bonding foundry business.

The company will also strive to raise the level of bonding processes by engaging in close information exchanges with D-process, as a way of expanding sales of its room-temperature bonding machines.

Meanwhile D-process, which primarily deals in CMP services and is seeking to expand and improve its bonding services segment, will develop a customer base for room-temperature bonding.