Swiss team produces purest green LED

Chemical engineers from ETH Zurich have succeeded in generating ultra-pure green light for the first time. The new LED, which is made from 2D perovksite using a room-temperature processe, could pave the way for visibly improved colour quality in a new generation of ultra-high definition displays for TVs and smartphones.

The device shows a maximum current efficiency (ηCE) of 13.02 cd A"“1 and the CIE 1931 colour coordinates of (0.168, 0.773). The colour gamut covers 97 percent and 99 percent of the Rec. 2020 standard in the CIE 1931 and the CIE 1976 colour space, respectively, representing the 'greenest' LEDs ever reported. By comparison, the purest colour TV displays currently available on the market cover on average only 73.11 to 77.72 percent; none exceeds 80 percent.

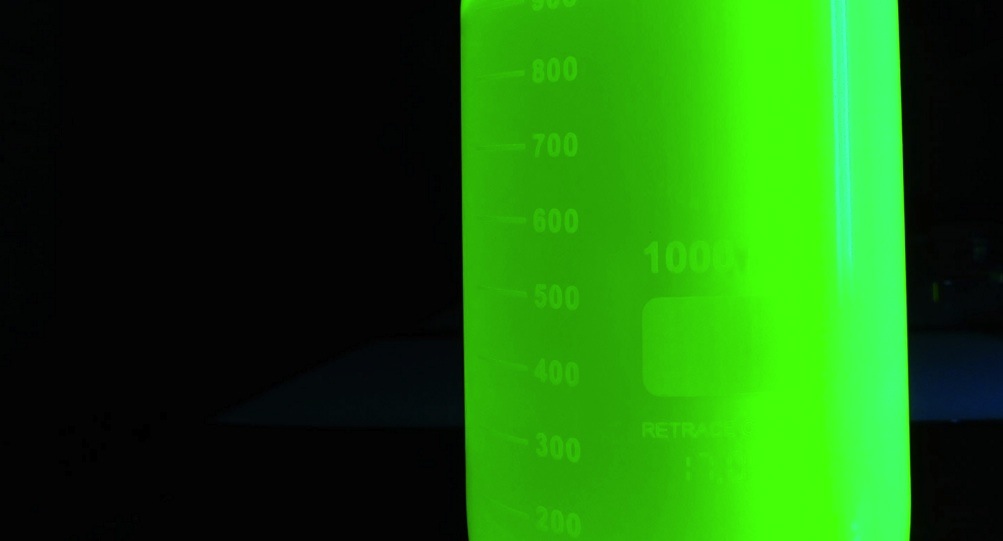

Moreover, the device shows only a ∼10 percent roll-off in ηCE (11.3 cd A"“1) at 1000 cd m"“2. The team has also demonstrated large-area (3 cm2) and ultraflexible (bending radius of 2 mm) LEDs based on these 2D perovskites.

This is due mainly to human perception, since the eye is able to distinguish between more intermediary green hues than red or blue ones. "This makes the technical production of ultra-pure green very complex, which creates challenges for us when it comes to developing technology and materials," says Sudhir Kumar, co-lead author of the report.

It becomes clear from reference to the Rec.2020 standard just how much progress the ultra-green light has made in the development of the next generation of displays. The international standard defines the technical requirements for ultra-high resolution (known as Ultra HD) displays and provides a framework for further research and development. The requirements also include an improvement in colour quality visible to the naked eye. The standard provides the colour scale that a display can reproduce and therefore a broader range of colour hues.

Ultra-pure green plays a key role in extending the colour range, or gamut. Ultimately, new hues are created through the technical mixture of three base colours: red, blue and green. The purer the base colours, the broader the range of hues a screen can display.

Wendelin Stark, ETH Professor of Functional Materials Engineering, along with researchers from South Korea and Taiwan, also contributed to the project results, which have been published in the scientific journal Nano Letters.

'Ultrapure Green Light-Emitting Diodes Using Two-Dimensional Formamidinium Perovskites: Achieving Recommendation 2020 Color Coordinates', by Kumar S, Jagielski J, Kallikounis N, Kim Y-H, Wolf C, Jenny F, Tian T, Hofer CJ, Yu-Cheng Chiu Y-C, Wendelin JS, Lee T-W, Shih C-J: Nano Letters, 3 August 2017.