GaN doped with beryllium - the way forward?

How to cut down energy loss in power electronics? The right kind of doping, according to researchers at Aalto University

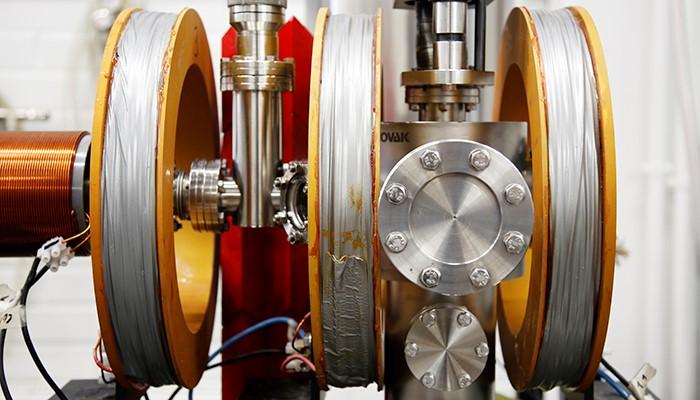

Working with scientists in Texas and Warsaw, researchers at Aalto University have managed to show - thanks to advances in computer modelling and experimental techniques - that beryllium can perform useful functions in GaN.

"There is growing demand for semiconducting GaN in the power electronics industry. To make electronic devices that can process the amounts of power required in, say, electric cars, we need structures based on large-area semi-insulating semiconductors with properties that allow minimising power loss and can dissipate heat efficiently. To achieve this, adding beryllium into GaN - or 'doping' it - shows great promise," explains Filip Tuomisto from Aalto University.

Experiments with beryllium doping were conducted in the late 1990s in the hope that beryllium would prove more efficient as a doping agent than the prevailing magnesium used in LED lights. The work proved unsuccessful, however, and research on beryllium was largely discarded.

The article published in Physical Review Letters shows that depending on whether the material is heated or cooled, beryllium atoms will switch positions, changing their nature of either donating or accepting electrons. "Our results provide valuable knowledge for experimental scientists about the fundamentals of how beryllium changes its behaviour during the manufacturing process. During it - while being subjected to high temperatures - the doped compound functions very differently than the end result," describes Tuomisto.

If the beryllium-doped GaN structures and their electronic properties can be fully controlled, power electronics could move to a whole new realm of energy efficiency, he says.

"The magnitude of the change in energy efficiency could as be similar as when we moved to LED lights from traditional incandescent light bulbs. It could be possible to cut down the global power consumption by up to ten per cent by cutting the energy losses in power distribution systems," says Tuomisto.