HRL Labs to Offer GaN MMIC Foundry Service

Custom integrated circuits for specific applications can be designed and fabricated at much lower cost

HRL Laboratories, - a corporate research lab owned by Boeing and General Motors in the US- has announced a new shared foundry service, offering advanced millimetre-wave (mmW) GaN technology for fabrication of monolithic microwave integrated circuits (MMICs) through multi-project wafer (MPW) runs.

"Eligible customers will be able to design into our world-class, state-of-the-art mmW T3-GaN fabrication process and receive custom, tailored circuits for their specific applications at a price much lower than a dedicated foundry run," said Shawn Burnham, the HRL scientist in charge of the GaN foundry service. "They will be given access to a process design kit, which has already been used to demonstrate world-record power amplifier and low-noise amplifier performance."

HRL T3-GaN is a leading-edge mmW HEMT technology for applications such as next-generation high-data-rate wireless communications and high-resolution radar imaging.

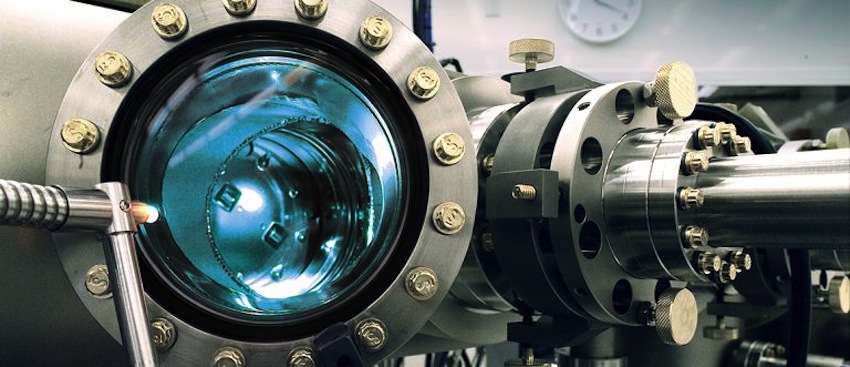

HRL processes GaN wafers in a 10,000-square-foot ISO Class 4 cleanroom, and is a US Department of Defense Trusted Foundry. HRL will begin an open subscription period soon for customers with verified US government end-use of the foundry product.

For customers that do not want to perform custom MMIC designs themselves, HRL also continues to offer related T3-GaN MMIC design services to US Government customers, which could then be used on MPW runs.

HRL has over 25 years of experience designing MMICs from UHF to mmW, including low-noise amplifiers, power amplifiers, mixers, switches, attenuators, and phase shifters, and the expertise to package the fabricated MMICs.