Siltectra expands HQ in Dresden

Pilot line for laser-thinning advanced SiC, GaN, and sapphire wafers already processing customer substrates

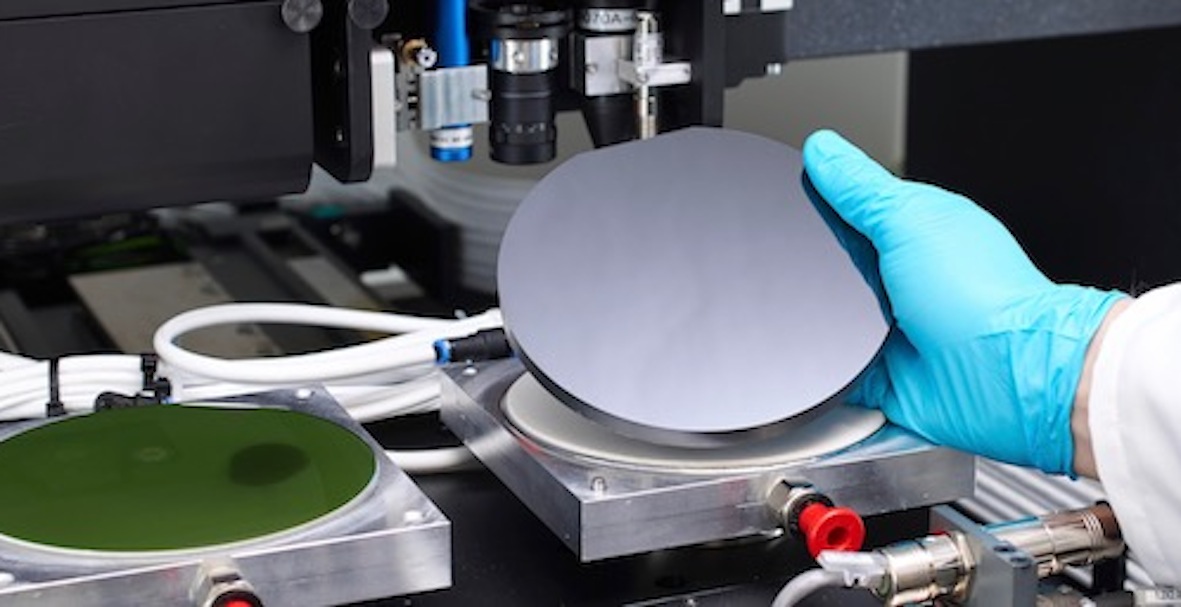

In a move that marks its shift to production, Siltectra has announced that it recently expanded its headquarters in Dresden's Technologie Park Nord and added a state-of-the-art pilot production line to the larger 900 square metre facility.

At the heart of the pilot line is the company's Cold Split laser-based wafer thinning technology, designed to cut costs for makers of devices based on advanced substrates like SiC, GaN, and sapphire, as well as silicon.

The new pilot line, which is already processing customers' substrates, is a central piece of Siltectra's growth strategy, says the company's CEO, Harald Binder.

"With the industry steadily transitioning to advanced substrates to build devices like power electronics, there is soaring interest in new technologies that can improve performance and contain costs. We're hearing daily from leading integrated device manufacturers (IDMs) who are eyeing advanced wafering technologies, in particular, to exact cost-reductions in their mass-production fabs.

This has generated high interest in our Cold Split technology. We're very pleased now to have advanced capabilities to cater to these customers."

Siltectra'S CTO, Jan Richter, added: "The pilot line gives us the critical infrastructure to accelerate our path to production and expand R&D to hit aggressive milestones on our technology roadmap. Cold Split is already out-performing traditional grinding methods by thinning wafers to 100 microns and below in minutes, with virtually no material loss.

Now, we're in final-phase testing of extended capabilities that exploit the technology's maximum potential. Results so far are very exciting. We believe that the additional innovations have the potential to deliver substantial cost savings to manufacturers of SiC-based devices."