CMOS competitor to InGaAs SWIR sensors?

Imec prototypes high-resolution image sensor with record small pixel pitch of 1.82 µm

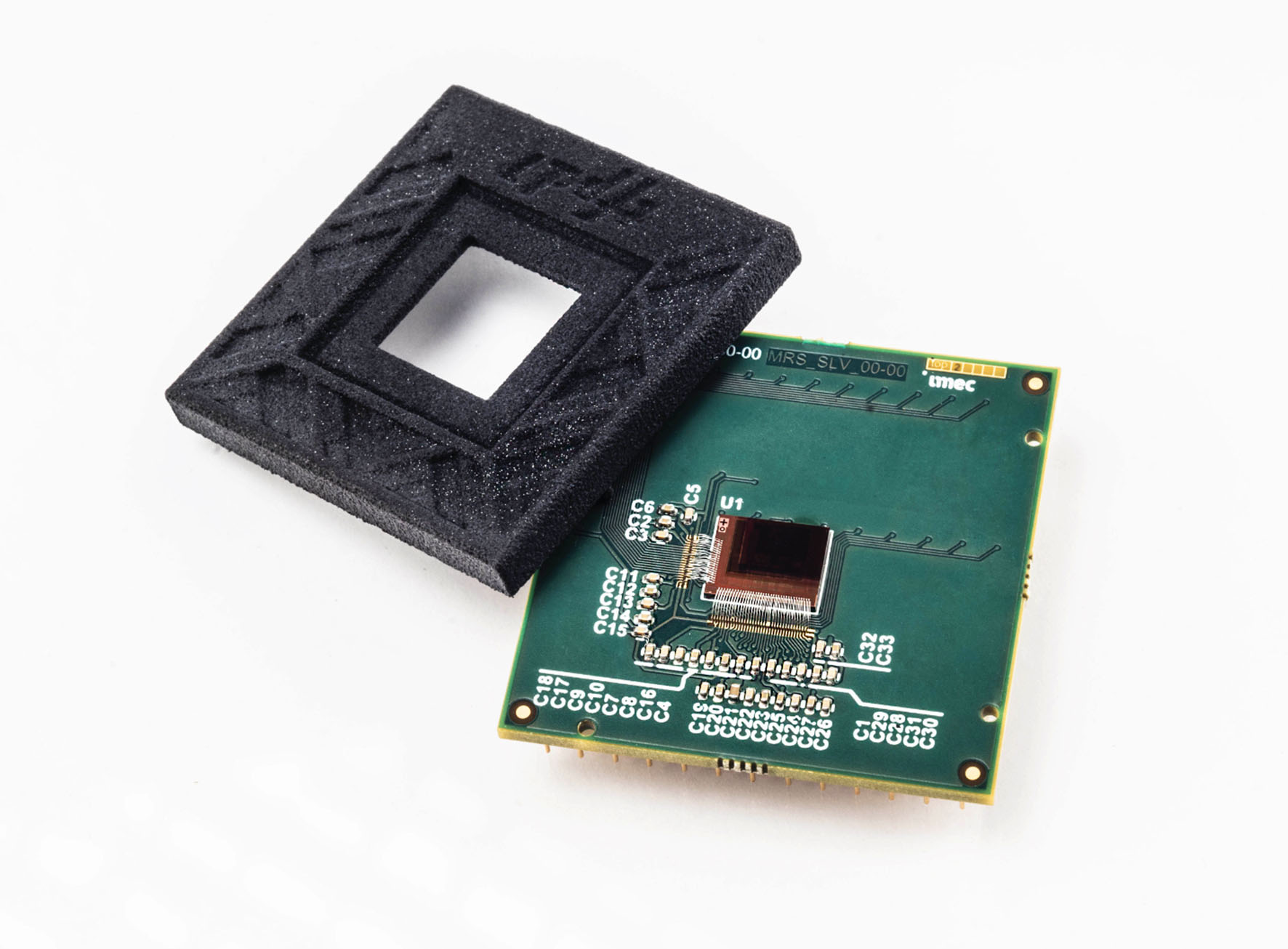

Imec has presented a prototype high-resolution short-wave-infrared (SWIR) image sensor with record small pixel pitch of 1.82 µm. It is based on a thin-film photodetector that is monolithically integrated on a custom Si-CMOS readout circuit.

A fab-compatible process flow paves the way to high-throughput, wafer-level manufacturing. The presented technology largely exceeds the capabilities of today’s InGaAs-based SWIR imagers in terms of pixel pitch and resolution, with disruptive cost and form factor potential. New applications are enabled even in cost-sensitive domains, such as in industrial machine vision, smart agriculture, automotive, surveillance, life sciences and consumer electronics. Imec will present these results at IEDM Conference 2020 in session 16.5.

Sensing in the short-wavelength infrared (SWIR) range (with wavelengths from around 1400 nm to above 2000 nm) offers advantages over the visible (VIS) and near-infrared (NIR) range for some applications. SWIR image sensors can, for example, see through smoke or fog, or even through silicon – which is especially relevant for inspection and industrial machine vision applications.

To date, SWIR image sensors are produced through a hybrid technology, in which a III-V-based photodetector (usually InGaAs-based) is flip-chip bonded to a silicon readout circuit. These sensors can be made extremely sensitive, but the technology is quite expensive for mass manufacturing and limited in size of pixel and number of pixels – hindering its adoption in markets for which cost, resolution and/or form factor are crucial.

Imec introduces an alternative solution that enables record small sub-2 µm pixel pitch, by monolithically integrating a thin-film photodetector stack with a Si-CMOS readout circuit. The photodetector pixel stack implements a thin absorber layer such as 5.5 nm PbS quantum dots – corresponding to peak absorption at 1400 nm wavelength. The peak absorption wavelength can be tuned by adjusting the nanocrystal size and is extendable to wavelengths even above 2000 nm.

At the peak SWIR wavelength, an external quantum efficiency (EQE) of 18 percent is obtained (and can be upgraded towards 50 percent with further improvements). The photodetector stack is monolithically integrated with a custom readout circuit, processed in 130 nm CMOS technology. In this readout circuit, the 3-transistor pixel design was optimized for the scaling of pixel size in the accessible 130 nm technology node, resulting in record small pitch of 1.82 µm for the prototype SWIR imager.

Pawel Malinowski, Imec’s thin-film imagers program manager: “With our compact, high resolution SWIR image sensor technology, we offer our customers a path to affordable low-volume manufacturing within imec’s 200 mm facility. These image sensors can be deployed in industrial machine vision (e.g. photovoltaic panel monitoring), smart agriculture (e.g. inspection and sorting), automotive, surveillance, life sciences (e.g. lens-free imaging) and many more. Due to their small form factor, they can potentially be integrated in small cameras, such as in smartphones or AR/VR glasses – with eye-safe SWIR light sources. Some of exciting future developments include increasing of the EQE (which currently is already at 50 percent in SWIR on test samples), reducing the sensor noise and introducing multispectral arrays with customized patterning approach.”

The prototype SWIR image sensor was developed in Imec’s Pixel Technology Explore research program. In this activity, imec collaborates with material companies, image sensor companies, equipment suppliers and technology integrators to develop accessible innovative and customized CMOS imaging technologies.