AlInN layers could boost LD and SLED performance

Swiss team develops new approach to manufacturing highly efficient blue-green laser diodes and superluminescent diodes

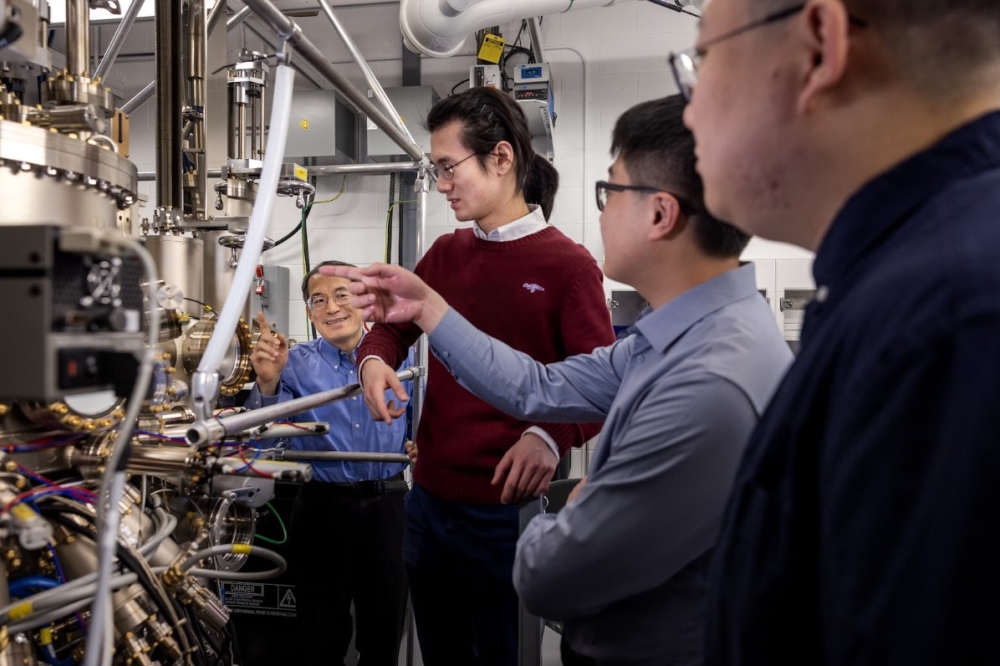

A study conducted by M. Malinverni and colleagues at the company Exalos in Switzerland has shown the potential of a novel epitaxial design featuring indium-aluminum-nitride layers (InAlN).

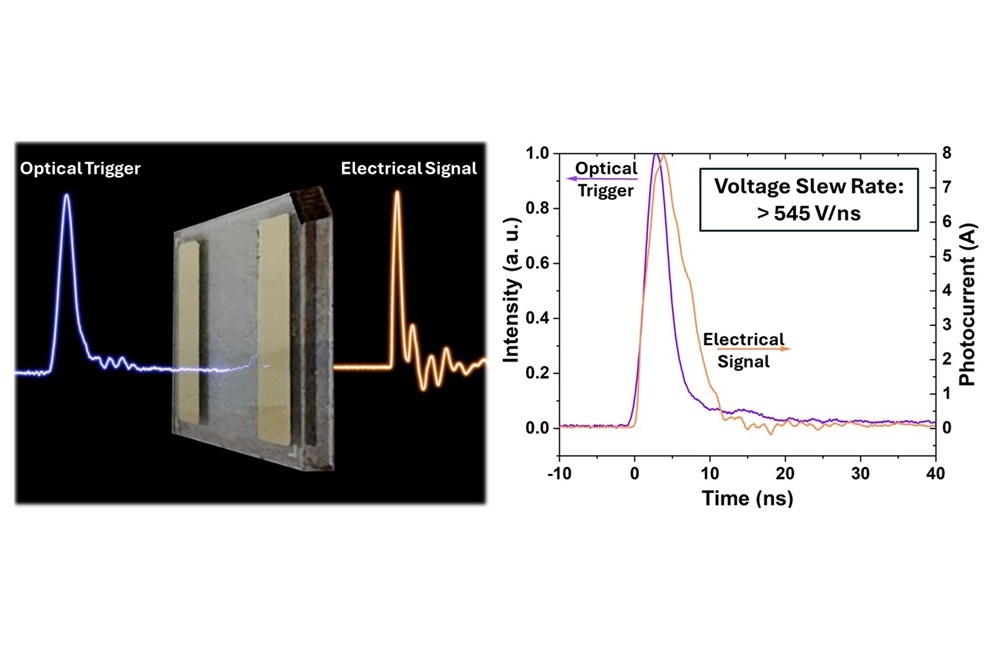

The researchers believe this approach holds the key to manufacturing highly efficient blue-green laser diodes (LDs) and superluminescent diodes (SLEDs).

“This breakthrough paves the way for the widespread adoption of InAlN in the manufacturing of next-generation optoelectronic devices and unlocks a path towards the development of efficient emission at longer wavelengths” said Malinverni.

The work, published in two recent journal articles and presented at the recent SPIE Photonics West conference, takes advantage of the properties of InAlN.

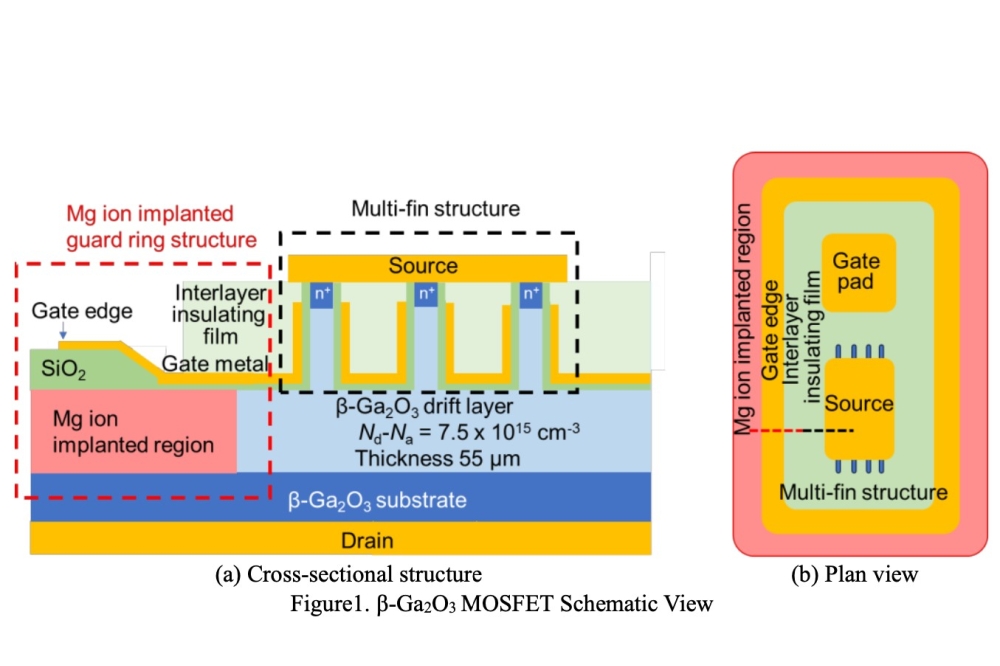

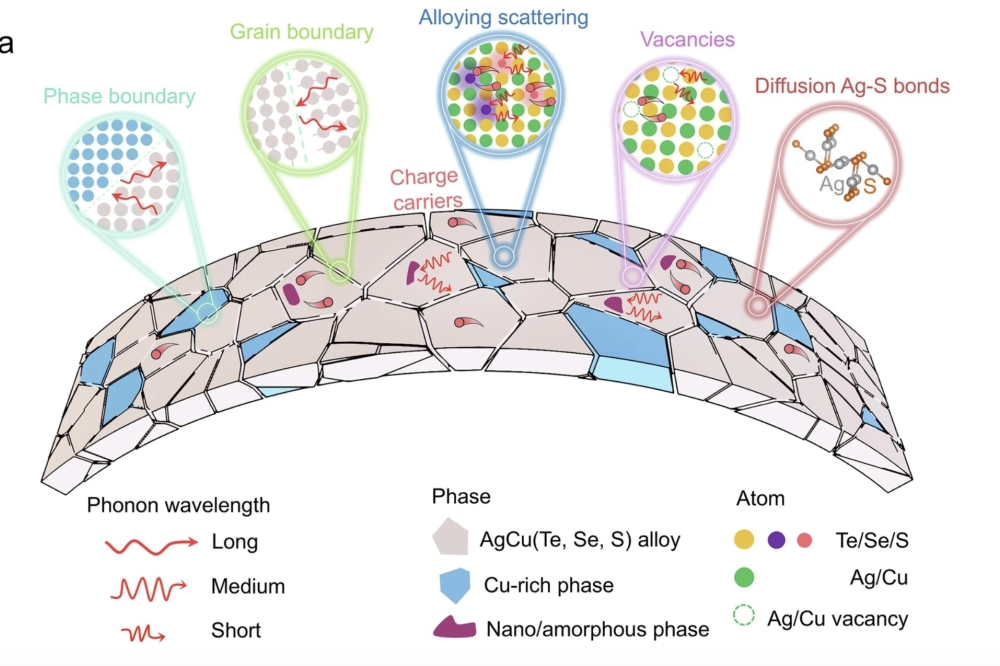

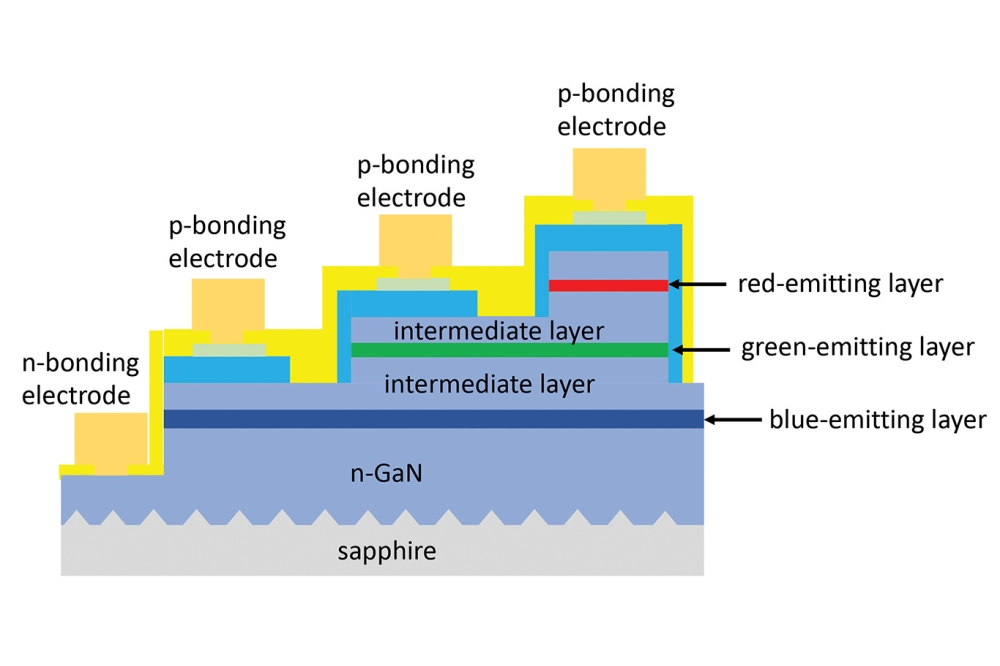

With an 18 percent indium composition, InAlN is lattice-matched to GaN and offers a fourfold increase in refractive index contrast to waveguiding layers when compared to conventional AlGaN. This feature positions InAlN as an ideal cladding candidate for LDs and SLEDs.

Despite being proposed two decades ago, the implementation of InAlN in commercial devices faced challenges, particularly in terms of rapid morphological degradation when growing thick layers, and also electrical transport issues through the interface of InAlN with the surrounding layers.

However, the researchers overcame both obstacles. The challenges related to the growth of thick layers were tackled by introducing an n-type cladding design based on multiple GaN/InAlN pairs, resulting in devices with enhanced optical confinement factors and, consequently, improved power efficiency. Efficient current transport and low resistivity was achieved through the optimisation of doping and growth conditions at the GaN/InAlN interfaces. The study optimised vertical carrier transport across InAlN/GaN interfaces, leading to negligible voltage penalties compared to devices with conventional AlGaN claddings.

Through the new design, LDs with a low threshold currents of 3 mA in the blue spectral range and 12 mA in the green were achieved. Furthermore, a noteworthy 85 mA decrease in operating current was reported for state-of-the-art green SLEDs.

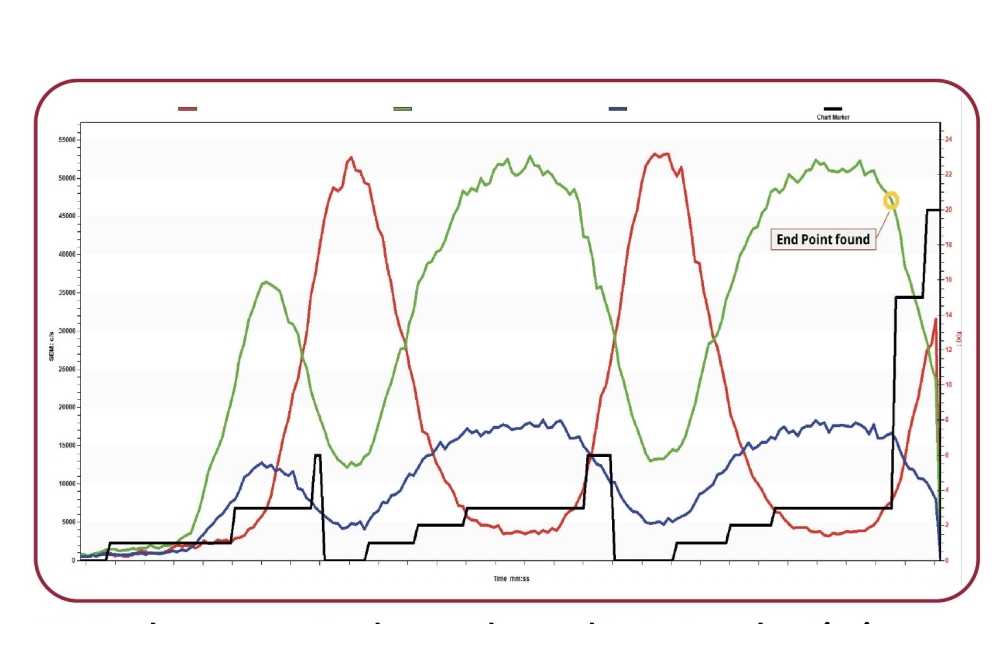

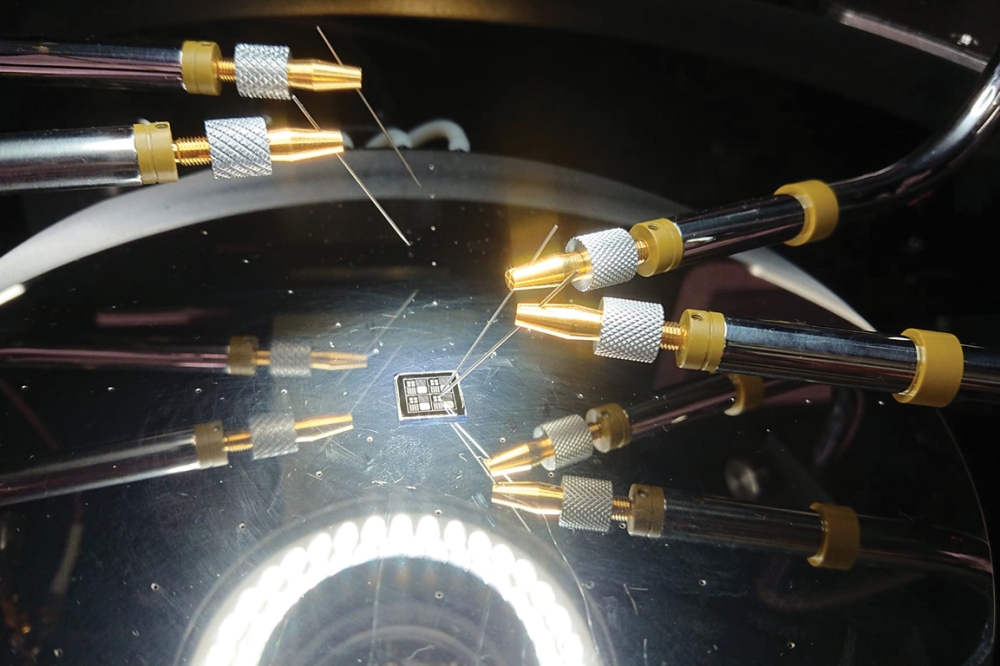

The study employed a combination of experimental data and simulations to delve into the strengths and challenges of InAlN claddings. The investigation proves a significant modal gain increase through the analysis of laser chips with multiple cavity lengths and various facet coatings. This aligns with the expected rise in optical confinement factor obtained through optical mode simulations.

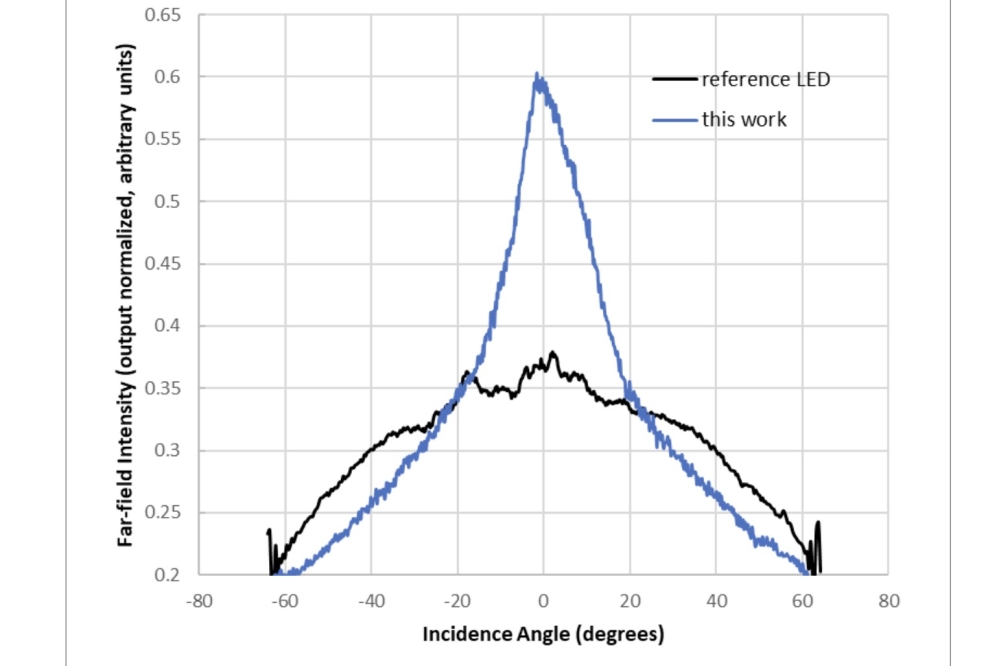

The research also explores the reduction of optical mode leakage towards the substrate that typically afflicts conventional devices with AlGaN claddings, resulting in a remarkable improvement in far-field light emission patterns when using an InAlN bottom cladding.

References

'InAlN cladding implementation in green superluminescent diodes and lasers' by M. Malinverni et al; Appl. Phys. Lett. 122 (20) (2023)

'Blue and Green Low Threshold Laser Diodes With InAlN Claddings' by M. Malinverni et al; IEEE Photonics Technology Letters, vol. 35, no. 24, pp. 1303-1306, (2023).

'The crucial role of InAlN for blue and green LDs and SLEDs with low power consumption' by M. Malinverni et al, submitted for publication in Gallium Nitride Materials and Devices XIX, SPIE. (2024).