XDC and Lumileds develop novel 140 ppi µLED display

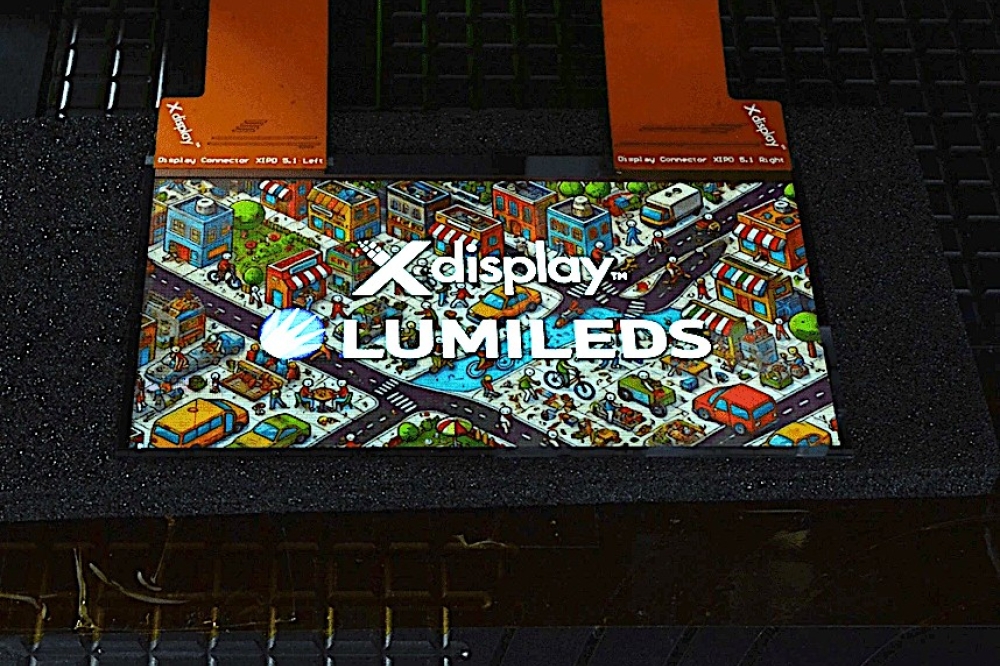

X Display Company (XDC), a developer of semiconductor devices for displays, and LED company Lumileds have developed a 140 pixels per inch (ppi) microIC-driven microLED prototype display.

MicroICs are an XDC innovation that integrate the display driver with the emitters, replacing the traditional TFT backplane to bring benefits in power consumption and visual performance.

The companies describe the novel display technology as marking milestone for microLED displays in mobile consumer applications including smartwatches, smartphones, tablets, and PCs.

“We see a lot of potential for microLED displays in mobile consumer electronic devices” said Ross Young, CEO of DSCC. “This XDC and Lumileds breakthrough will improve the cost, power, and brightness display profile significantly as to help accelerate adoption of these technologies.”

The new microLED display has an architecture based on a cluster drive system combined with microLEDs that measure 13x20 µm². The result is a peak brightness of 2360 cd/m². Notably, the mass transfer process employed in the development of these prototypes achieves 99.9998 percent microLED sub-pixel yield and a 99.992 percent percent microIC transfer yield, according to the partners. The processes used to manufacture the prototype are mass-production ready.

“XDC’s mass transfer, bonding, and display driving technologies have created new opportunities to transform the world of displays,” said Brendan Moran, senior director of Display Technology at Lumileds. “Lumileds has successfully implemented XDC’s transfer-ready microLED technology into our volume production LED fabrication facilities. Together, we are setting new standards in the microLED industry and advancing mobile display technology.”

“This milestone is made possible by Lumileds’s device expertise and manufacturing process discipline applied from the very start. The result is repeatable, high-quality microLED displays,” said Matt Meitl, EVP and co-founder of XDC. “Our long collaboration has resulted in microLED displays sought by customers in the mobile device space.”

The microICs, microLEDs, and the transfer equipment used in this prototype can be deployed for interested customers.